Flexible Perovskite Solar Cells: The Future of Wearable Solar Technology?

Technical Analysis | 21-03-2023 | By Liam Critchley

Perovskite solar cells have been gaining a lot of interest in recent years and are seen as one of the front-running technologies that could displace traditional silicon-based solar cell architectures. Perovskite solar cells are being developed in many forms, from using perovskites on their own in the photovoltaic (PV) junction to being used in a hybrid form alongside other materials, as well as in nanoscale thin-film forms.

One of the main reasons for the interest in perovskite solar cells is that they can achieve very high-power conversion efficiencies (PCEs) of over 25% as a single junction cell (and around 30% PCE currently for tandem solar cells). They are also lightweight, are relatively low cost, and there are a number of different materials within the material class which can be exploited to meet the demands of various applications. The main application focus for perovskite cells has been in traditional bulkier solar cell architectures, and there are now perovskite-based solar farms being trialled.

Another application that has recently gathered interest is to use of perovskite solar cells in wearable technologies, and because thin films can be made of perovskite materials, they can be made to be more flexible compared to when they’re used in bulkier solar cell architectures. While there’s a lot of potential for perovskite solar cells on all fronts, there are still several challenges that need to be ironed out before they can displace silicon as the go-to PV technology.

Each type of perovskite PV architecture and application has different challenges based on how the materials are integrated and used, and for perovskite-based PVs in wearables, one of the main challenges is their long-term reliability and operational stability due to the presence of defects that accumulate at the interfaces between the different materials. Researchers have now attempted to overcome these defect challenges and create more effective and stable perovskite solar cell devices that are compatible with wearable technologies.

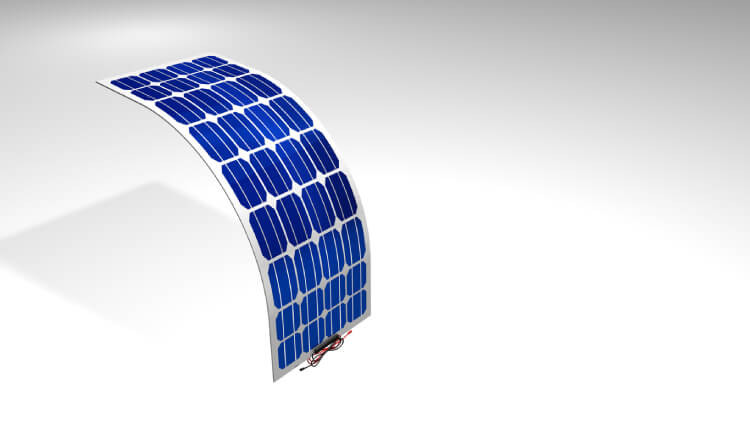

3D model of a flexible solar panel with black and red connection cables, set against a white background

Issues with Interfacial Defects

In any PV technology, there is a junction that is composed of an electron-rich material on one side of the junction and a hole-rich material on the other side. In some cases, this can be the same material (e.g., silicon) but doped in different ways to give each side different charge carrier properties, or it can be different materials altogether that have different charge carrier properties. At the junction, the holes and electrons recombine to form a depletion zone that stops the PV from producing energy when there’s no solar stimulus (and when sunlight hits the PV, the energy is transferred to the different charge carriers that gain enough energy to overcome the depletion zone).

At this junction, there are a number of interfaces where defects can arise. The recombination of charge carriers from the charge transport layers can increase the interfacial area between the perovskite material and the charge transport layers. While defects can occur at all or any of these interfaces, they are more prevalent at the bottom interface where the perovskite meets the hole transport layer.

The bottom interface in many smaller-scale perovskite devices often contains a high concentration of defects, many of which are deep-level defects that can induce hysteresis and irreversible degradation to the junction, which impacts their long-term stability and operational performance. Many strategies for removing these defects and/or creating architectures that do not fall privy to these defects have been proffered―from interpenetrating interfaces to scaffolds to the addition of additives―and researchers have turned to liquid crystal elastomers to reduce the interfacial defects in these devices.

Using Liquid Crystals to Develop Wearable Perovskite Solar Cells

Liquid crystal elastomers (LCEs) are a type of cross-linked polymer network that form via self-assembly and exhibit a combination of the anisotropy (directionally dependent) properties that liquid crystals have with the elasticity properties of polymers. How these elastomers behave within an application is dependent on the alignment of the liquid crystal phases within the elastomeric network. The behaviour of these elastomers can be tailored through functionalisation and hybridisation approaches to build functional composites that have a range of properties―including surface resistivity properties that make them suitable for flexible solar cell applications.

Researchers have created some thin-film flexible perovskite solar cells that can be used with wearable technologies by creating a well-aligned thiol-terminated LCE layer that acts as a toughening charge transfer channel between SnO2 and perovskite thin films. The molecular ordering of the monomer constituents within the LCE are instantly locked upon irradiation with sunlight (a photopolymerisation approach). This locking approach enabled the interlayers to minimise charge recombination at the SnO2/perovskite interface, making the PV device more stable, reliable, and efficient.

The ability to maintain charges and not let them recombine resulted in a device with a PCE of up to 23.26% for rigid devices and a PCE of up to 22.1% for flexible devices. Because stability has been an issue with these devices in the past, this was also tested using an unencapsulated device (i.e., no polymeric coating protection on the surface of the device). The device showed a T80 lifetime―the time at which the device efficiency reduces to 80% of the initial value―of over 1570 hours. With standard encapsulation methods, these values could be increased further.

All the devices exhibited excellent repeatability and reliability characteristics, as well as excellent mechanical properties. The ability to flex and bend without breaking is critical for wearable devices, and the devices retained 86% of their initial efficiency after 5000 bending cycles. As well as developing the solar cells by themselves, the finished modules were also integrated into a wearable haptic device that contained microneedle-based arrays of sensors to demonstrate a pain sensation system in virtual reality...

So, while perovskite solar cells have their challenges―especially in thin film form―this research goes some way to improving the prospects of these types of PV devices, going so far as to not only create devices that have high efficiencies, reliability and mechanical endurance, but it also showcased the ability for these devices to integrated into wearable devices and provided a glimpse into what the future of these devices might look like.

Reference: