SiC Power Modules Driving Military Electrification

Insights | 18-06-2025 | By Gary Elinoff

Laser Weapons will depend heavily on Silicon Carbide (SiC) Semiconductors.

Key Takeaways about SiC Power Modules: The New Backbone of Military Electrification:

- Modern power converters based on wide bandgap semiconductors offer many advantages over last-generation devices based on large AC transformers.

- SiC transistors are able to handle more power than Gallium Nitride (GaN) devices.

- The attributes of SiC transistors have already sparked a revolution in civilian industry, and now the Military is joining the movement.

SiC Power Modules and Military Electrification

Hybrid electric vehicles based on silicon carbide (SiC) are already in use in the commercial sector, and the Military is becoming more interested. Due to SiC's unique qualities, it's also being used in a wide range of other military applications. But in order to understand this rather significant evolution in military technology, we'll first have to take a short (I promise!) detour into Wide Bandgap (WGB) semiconductor technology.

Wide Bandgap Semiconductors: SiC vs GaN

When you're Talking Power, you're Talking Silicon Carbide (SiC). SiC, along with Gallium Nitride (GaN), are both WBG Semiconductors. The term WBG refers to the energy gap between the semiconductor material's conduction and valence bands. This phenomenon allows WBG-based power semiconductors to switch ON and OFF at far higher speeds than classical silicon-based devices. Power densities are also greater, which means that smaller devices can handle more power.

SiC is more expensive than GaN and doesn’t switch quite as fast, making the trade-offs between SiC vs GaN power semiconductors a key design consideration in high-efficiency military systems. However, a SiC device of the same size can handle more power than its GaN counterpart. SiC devices can not only operate in higher ambient temperature environments, but they also do a better job of dissipating heat, needing less heat sinking. SiC semiconductors often employ vertical transistor structures, which endow them with more resistance to physical stress than their GaN cousins.

SiC is a relatively new technology, and not all power engineers are well acquainted with it. Supply chains are still a bit iffy but are rapidly improving, as is manufacturing know-how, driven in part by the rapid growth in SiC and GaN markets.

Why High-Speed Switching Matters in SiC Devices

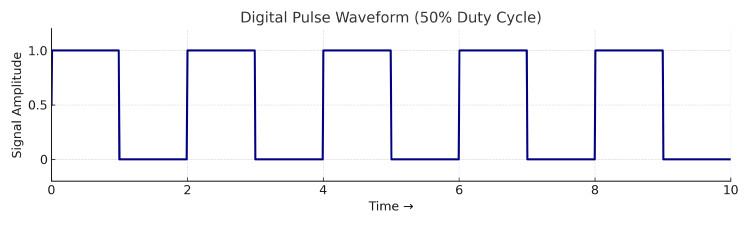

When we refer to switching, we describe the ability of a transistor to turn completely ON or OFF, as illustrated below.

DC to Pulsating DC. Image source. Electropages

The waveform is called pulsating DC, and because WBGs can switch very quickly, there can be thousands or hundreds of thousands of pulses each second. If these pulses are presented to a transformer's primary, they behave very much like AC, and as such, the voltage of the AC that appears on the secondary is controlled by the transformer's turn ratio. This is the basic idea behind tuning DC into AC. In a similar manner, AC can be tuned into DC.

Because of the high switching frequencies, smaller and lighter transformers and associated components can be employed. And because WGBs exhibit less internal resistance than classical Silicon (Si) transistors when they switch ON, far less power is wasted, generating less parasitic heat, a hallmark of the efficiency of SiC in high-power electronics.

SiC Traction Inverters in Military Vehicles

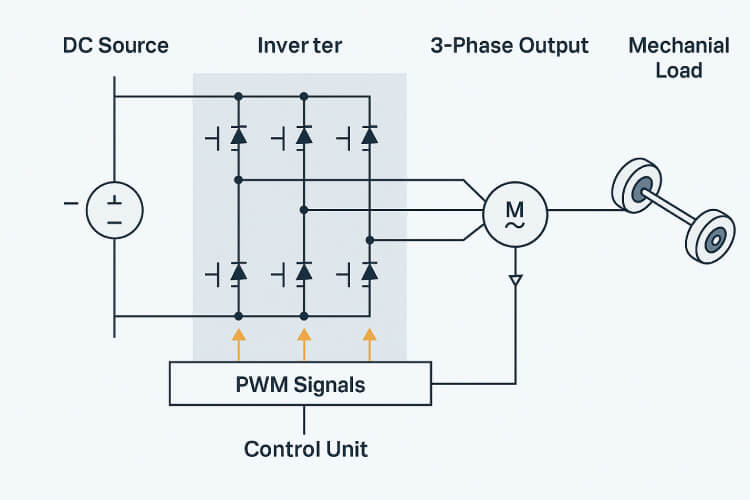

The motors that propel electrified vehicles are called Traction Motors. The function of a Traction Inverter is to convert the DC from a vehicle's lithium-ion battery (LiB) into the 3-phase AC that the traction motor requires.

Traction inverters are an amalgamation of six wide-bandgap semiconductors, forming a system rooted in the principles outlined above and proven effective in SiC, improving EV range and performance.

Functional diagram of a traction inverter and motor.

For EVs, GaN devices will often do. They're cheaper, the supply train is more robust, and engineers are more familiar with the underlying technology. But for the Big Boys, we're about to describe, SiC is the hands-down favorite.

Military Hybrid Vehicles and SiC Inverters

For all the hype, the Military seems to be moving ahead—very slowly—mainly with hybrid vehicles and not fully electric vehicles. The obvious reason is that it's relatively easy to move hydrocarbon fuel up to the front where combat vehicles are operating. Moving stored electric power and charging a vehicle's battery in the field is still difficult and untested compared to dealing with gasoline, diesel, or JP-8.

It should be noted that many of the Military's hybrid electric projects seem to be being considered in tandem with projects related to autonomous or semi-autonomous vehicles. So now, let's take a look at some of the prospects in the pipeline.

PICHOT SiC Inverter Boosts Army Vehicle Range

As described by the National Renewable Energy Laboratory (1)sign the vehicles of the future, you might think you need a sweeping overhaul of the entire system. But sometimes, reimagining a single component can lead to transformational results." Case in point – the new PICHOT power inverter, newly conceived to deliver 200 kW of AC power. The Pichot not only makes the added 200% range possible but also has a footprint that is only one-quarter the size of its predecessor.

DEVCOM will lead the development effort along with participants from NREL and the Army Research Laboratory (ARL). The PICHOT has been conceived from the beginning to be modular, designed to slot into a wide array of hybrid-electric ground combat vehicles, ranging from light-wheeled vehicles to the mighty Abrams main battle tank.

Another innovation incorporated by the shoe-box-sized device is its integration with vehicle cooling systems. This eliminates the need for PICHOT to be packaged with large, heavy coolant reservoirs or cold plates. No need either for messy, bulky communications wiring, as the traction inverter communicates with the vehicle's control systems wirelessly.

Calnetix SiC Inverter Powers Combat Vehicles

Calnetix's Enercycle DC-1000[2] inverter is a bidirectional (both AC/DC and DC/AC) inverter. It achieves up to 98.% efficiency thanks to its high switching frequency and switching speed, which is made possible by the use of SiC power transistors.

Calnetix DC-1000. Image source: Calnetix

The US Army Ground Vehicles Systems Center (GVSC) is developing, integrating and testing electrification and hybrid electrification technologies in support of Next Generation Combat Vehicle platforms. As part of GVSC's Powertrain Electrification and Mobility (PEM) effort, the DC-1000 inverter is initially targeted for the Army's Robotic Combat Vehicle (RCV-M) and Optionally Manned Fighting Vehicle (OMFV) Tracked Vehicle Variants.

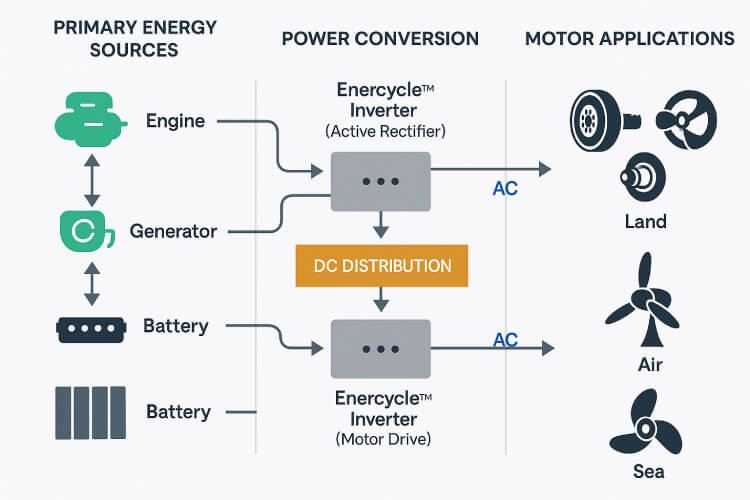

The application of the DC-1000 is centered around the DC bus. On the left side of the diagram illustrated below, the engine's generator provides AC to the inverter, which provides DC for the DC bus. The DC bus can charge batteries or, when needed, take power from the batteries.

Electrical power from the central DC bus must be converted to the 3-phase AC needed to power the motors that will propel the vehicle. For that purpose, a separate Enercyle unit is employed, as illustrated at the top right, in its DC to AC mode. Because the DC-1000 is also proposed for naval and aeronautic purposes, the lower right portion of the diagram illustrates that possibility.

Application of the DC-1000. Image source: DC-1000 Data Sheet

As described in its data sheet, the device is sized at 23 x 18 x 6 inches. It operates over ambient temperature ranges of -40 to 120℃. It can provide 500 kW continuous power and 640 kW on a transient basis.

Naval Hybrid Systems Powered by SiC Modules

Hybrid-electric propulsion systems represent a significant advancement in naval engineering, integrating the efficiency of electrical systems with the robustness of traditional power sources. This approach maximises performance, reduces emissions, and improves the operational flexibility and maintainability of naval vessels.

USS Zumwalt's Integrated Power System (IPS)

The USS Zumwalt exemplifies state-of-the-art naval hybrid-electric propulsion technology. Instead of directly propelling the ship via diesel-driven gas turbines, these turbines generate electricity, feeding into the Zumwalt's sophisticated Integrated Power System (IPS). The IPS harnesses advanced Silicon Carbide (SiC) inverters, critically linking generated power to two high-capacity, 35 MW induction motors driving the propeller shafts.

SiC inverters substantially outperform conventional silicon-based Insulated-Gate Bipolar Transistors (IGBTs). Their inherent advantages include faster switching speeds, reduced thermal generation, higher efficiency, and lower cooling demands. Such benefits enhance overall system performance, reliability, and operational economy.

Navy's Power Electronics Building Block (PEBB) Program

The U.S. Navy has expanded these principles through its Power Electronics Building Block (PEBB) initiative. The programme promotes modular, scalable power converters, adaptable across multiple naval platforms. With a strategic push towards higher efficiency and reduced operational costs, efforts focus on leveraging SiC semiconductor technology at increased operating frequencies to optimise power delivery and density, essential for next-generation vessels.

Royal Navy's Type 26 Frigate Programme

Similarly, the Royal Navy is actively evaluating SiC-based solutions within its Integrated Full Electric Propulsion (IFEP) systems, notably for the new Type 26 frigates. Collaborative efforts between industry leaders such as General Electric (GE) and Rolls-Royce underscore the growing international momentum toward adopting SiC technology for its superior efficiency, reduced lifecycle costs, and improved power management capabilities.

Directed Energy and Radar: SiC’s Naval Role

Naval vessels increasingly rely on advanced power electronics leveraging Silicon Carbide (SiC) semiconductors to enhance system performance, efficiency, and reliability. Beyond propulsion systems, SiC plays a crucial role in supporting cutting-edge naval technologies such as directed energy weapons and sophisticated radar systems.

Directed Energy Weapon Systems (DEWS)

Directed energy weapon systems employ highly focused energy beams rather than traditional kinetic or explosive-based methods to neutralise targets. These revolutionary systems offer precision, rapid response, and the capability to engage diverse threats, ranging from unmanned drones to advanced ballistic missiles. Currently, the United States and the United Kingdom are actively developing and deploying DEWS as part of their naval defensive capabilities.

HELIOS (High Energy Laser with Integrated Optical-Dazzler and Surveillance)

HELIOS is a leading example of naval directed-energy technology, featuring a powerful 60 kW solid-state laser. Primarily designed to blind or disable the sensors of incoming unmanned aerial vehicles (UAVs) and other threats, HELIOS relies extensively on SiC MOSFET technology. SiC MOSFETs efficiently convert the ship’s main electrical bus voltage into DC power suitable for laser operations. Additionally, SiC components facilitate rapid charging of the system's battery banks and supercapacitors, ensuring sustained energy availability and enabling a high rate of fire during prolonged engagements.

Advanced Naval Radar Systems

SPY-3 Radar System

The advanced SPY-3 radar is integral to the sophisticated sensor arrays aboard the U.S. Navy’s Zumwalt-class destroyers and Ford-class aircraft carriers. Utilising phased-array technology, SPY-3 delivers superior detection, tracking, and engagement capabilities. Silicon Carbide plays a pivotal role in the radar’s power conversion systems, optimising AC/DC and DC/DC conversions. By employing SiC components, SPY-3 achieves higher efficiency, improved thermal management, and enhanced reliability, contributing significantly to the system’s long-term performance and operational readiness.

SiC Power Modules: Future of Military Systems

GaN serves many purposes, but it simply doesn't have SiC's power-handling capacity. SiC semiconductors can also operate at higher temperatures, can deal with more mechanical stress and can do a much better job of dissipating heat. Importantly, they have higher power densities, so they take up less space, a key factor in military applications.

They also mirror advancements in SiC and GaN in renewable energy systems, where power density and efficiency are equally critical. While directed energy weapons, such as high-energy laser systems, have been a staple of science fiction for decades, the capabilities of silicon carbide have moved them into the realm of military reality.

Challenges and Growth Ahead for SiC in Defence

If a nationwide charging network were to be built in the US, the near-universal adoption of EVs would be possible. Of course, a charging network can't be established in a combat zone. For that reason, fully electric manned combat vehicles are not likely to come any time soon, but hybrid-electric vehicles offer many advantages.

However the Military is deeply into developing autonomous vehicles, and here the use of all electric drives is being considered. And throughout the Military, electricity, and especially very high power electricity, is becoming more prevalent in present applications and future plans. While GaN may serve the purpose of civilian vehicles, the added power handling capacity of SiC will be essential for the Military's electric future.

A key to continued development will be engineers' better understanding of SiC. And, more research into more effective manufacturing techniques will be necessary, as well as strengthening the supply chain.

FAQs About SiC in Military Systems

Why is SiC preferred over GaN in military vehicles?

SiC handles higher voltages, higher power loads, and extreme thermal environments better than GaN, making it the preferred choice for rugged, high-reliability military systems such as hybrid-electric vehicles and combat inverters.

What are the advantages of SiC power modules in defence applications?

SiC power modules offer higher efficiency, reduced heat generation, smaller size, and better thermal conductivity. These benefits make them ideal for military power conversion systems, laser weapons, radar, and electric propulsion.

How are SiC inverters used in military ground vehicles?

SiC inverters are used to convert DC battery power into three-phase AC for traction motors in hybrid or electric military vehicles. They enable lighter, more efficient drive systems with improved range and battlefield performance.

Are SiC semiconductors used in naval systems?

Yes. SiC technology is used in naval integrated power systems, hybrid-electric propulsion, and directed energy weapon platforms. It supports high switching frequencies and reduces the weight and size of onboard power systems.

What challenges are limiting the adoption of SiC in the military?

Current limitations include high material costs, limited supply chain maturity, and the need for specialised manufacturing and engineering expertise. However, these barriers are being actively addressed as defence electrification accelerates.

Is SiC better than traditional silicon for military electronics?

Yes. Compared to traditional silicon, SiC offers faster switching, greater power density, and superior thermal performance — all essential in compact, high-power military electronics used in extreme environments.

Glossary of Terms

Traction Inverter: An array of semiconductors devised to convert DC power into AC, generally to power a vehicle's AC traction motor.

Wide Bandgap Semiconductors: Due to their atomic structure, these devices can handle more power, operate at higher frequencies, and handle mechanical and thermal stress better than conventional semiconductors. In GaN’s case, limitations like poor P-type conduction continue to hinder adoption — a challenge discussed in GaN's barrier to semiconductor supremacy.

References

1. NREL Selected To Design Next-Generation Power Inverters for US Combat Vehicles – The National Renewable Energy Laboratory (NREL)

2. High-Frequency Inverter for Future Ground Combat Vehicles – Calnetix