Sodium-Ion Battery Safety Boosted by Smart Polymer Gel

Insights | 30-05-2025 | By Liam Critchley

Key Takeaways:

- Why it matters: Sodium-ion batteries use abundant, low-cost sodium instead of lithium, but their poor cycle life and safety have held back commercialization.

- What’s new: Researchers engineered a smart gel polymer electrolyte that self-crosslinks at high temperatures, creating a robust interphase and suppressing gas evolution and dendrite growth.

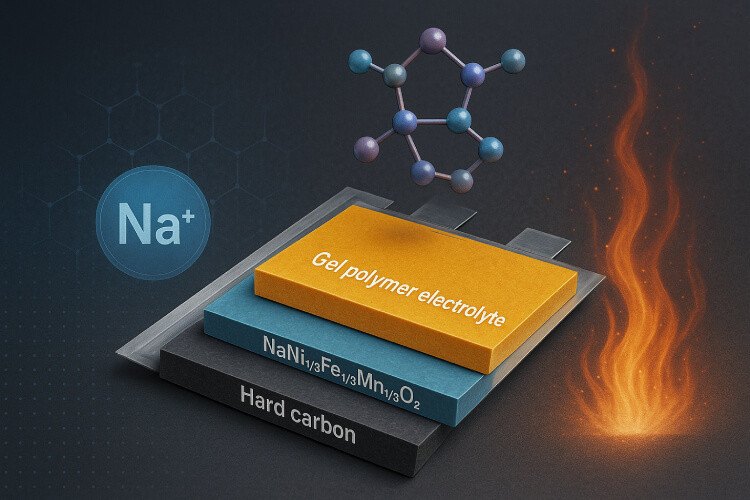

- Key performance gains: In NaNi1/3Fe1/3Mn1/3O2 / hard-carbon pouch cells the electrolyte raised the thermal-runaway onset from 137 °C to 177 °C and preserved 80 % capacity after 500 cycles at 50 °C.

- Big picture: This chemistry charts a path toward longer-lasting, intrinsically safer sodium-ion batteries for large-scale energy storage and other commercial uses.

Even though lithium-ion (Li-ion) batteries are the most ubiquitous battery technology today, other battery chemistries are sought that either have higher energy densities or use other metals to overcome the limitations of finite lithium resources.

Sodium-ion (Na-ion) batteries are one potential option that are being explored a lot more. While some commercial systems have emerged, like Li-ion batteries, there are many different versions that have different battery chemistries that can be explored.

Even though there are still challenges with Na-ion batteries, the scarcity and price fluctuations of lithium resources mean that the commercial advancement of Na-ion batteries is rapidly advancing―due to the cost-effectiveness and abundance of sodium in the Earth.

Many Na-ion batteries still fall below expectations and below that of commercially available batteries. For large-scale commercial applications, Na-ion batteries based on layered O3-type (ABCABC oxide ion stacking) sodiated transition metal oxide anodes (O3-NaxTMO2) and hard carbon cathodes have shown great potential.

However, these battery structures have a poor cycle and storage life, especially at higher temperatures and are also prone to thermal runaway. These performance issues have been attributed to the rapid degradation of the electrode and electrode/electrolyte interphase, but researchers have developed a smart polymer electrolyte to overcome these issues.

Challenges of These Na-ion Batteries

The main challenges faced by these batteries is that the anodes undergo a number of detrimental mechanisms during operation, including:

- Deleterious phase transitions

- Transition metal dissolution from the cathode

- Mechanical microcracking that can cause failure

- Electrolyte oxidation

- Releasing oxygen during thermal runaway that can lead to fire and explosions

For the cathodes, the cathode has a high solubility in conventional electrolytes (electrolytes such as NaPF6-carbonates). This means that the solid-interphase layer (SEI) on the electrode surface can be easily compromised, leading to an overconsumption of electrolyte, loss of active sodium from the electrode, and gas evolution reactions. Because the SEI dissolves, the cathode can become directly exposed to the electrolyte, leading to early-stage self-heating and a higher chance of thermal runaway occurring. The poor compatibility of conventional electrolytes in these batteries also leads to the formation of dendrites during cycling. All these factors ultimately lead to Na-ion batteries with longevity and stability issues that are not suitable for commercial applications, but researchers have been looking into alternative electrolyte compositions that are better suited to this class of Na-ion batteries.

The Potential for Polymer Gel Electrolytes

One of the electrolyte options that could be more suitable for Na-ion batteries is polymer gel electrolytes. These electrolytes have a high flexibility, are leak-proof, have a good interfacial compatibility, can be processed on large scales (for large scale commercial manufacturing) and have a high intrinsic safety. This combination of properties could help to develop Na-ion architectures that have a much-improved cycle life and safety.

Gel polymer electrolytes are also known to mitigate the dissolution and diffusion of ions from the electrode/electrolyte interface, as well as reduce the emission of thermally induced gas molecules that lead to gas buildup in the battery. Gel polymer electrolytes also exhibit ‘smart’ properties, where they can undergo additional crosslinking/polymerisation under thermal stress. This induced polymerisation blocks the transport of ions and reduces crosstalk effects to improve the safety of the battery. It’s thought that these smart gel polymer electrolytes could be used to improve Na-ion battery chemistries, but the battery chemistry does vary from Li-ion, and there has been no precedent set for developing these electrolytes for Na-ion batteries until now.

New Smart Polymer Gel Electrolyte Improves Na-ion Batteries

Researchers have developed a new smart polymer gel electrolyte for layered O3-type Na-ion batteries and used a hard carbon cathode and a NaNi1/3Fe1/3Mn1/3O2 (NFM) anode. The electrolyte was created using a thermally induced in-situ radical polymerisation method between a cyanoethylurea-containing methacrylate monomer and an isocyanate-based methacrylate monomer in a conventional NaPF6-carbonate electrolyte.

It was found that the cyano, isocyano, and urea functional groups in the electrolyte can form robust electrode/electrolyte interphase layers and improve both the thermal and electrochemical stability of the electrode while reducing the chance of electrolyte deposition. The enhanced stability of the electrolyte also prevents gas byproducts from being generated during operation, even at high temperatures. When the temperature inside the battery went above 120 °C, the urea and isocyanate groups in the electrolyte underwent further crosslinking that blocked ion transportation and prevented crosstalk effects, leading to a much more stable and safe battery at higher operating temperatures (which was confirmed using accelerated rate calorimetry).

These characteristics allowed the NFM battery to have an improved cycle life compared to using a standard electrolyte, even at elevated operation temperatures of 50 °C. This was showcased by the NFM battery―as a pouch cell―having an increased heat-releasing onset temperature of 80 °C to 103.6 °C and a thermal runaway onset temperature from 137.2 °C to 177.4 °C.

Overall, the longevity and cycle life of the NFM battery was improved thanks to the smart gel polymer electrolyte. In the tests, the NFM pouch cells maintained 80% of their original capacity after 500 cycles at an elevated temperature of 50 °C. Given the challenges with these Na-ion batteries in the past, the new electrolyte developed in this study shows a pathway for developing future electrolyte materials that can be used to impact a wide range of sustainable Na-ion battery chemistries to ensure that they last longer and are safer for use.

Reference: