3D Printed Self-Healing Liver Models: The Future of Surgery

Insights | 17-01-2024 | By Liam Critchley

Conceptual Image: 3D Printing an Artificial Liver, Illustrating Advances in Medical Technology. 3D Rendering on White Background.

Key things to know:

- Advancements in 3D printing technology have led to the development of more realistic liver models, enhancing surgical training and preoperative planning.

- New 3D printed liver models feature self-healing properties, mimicking the physical properties of the liver more closely than traditional models.

- Digital Light Processing (DLP) is used for printing these models, allowing for quick creation based on patient-specific CT data.

- Preliminary clinical trials demonstrate the effectiveness of these models in improving surgical outcomes and training, with a focus on replicating real organ deformation

Introduction

The development of 3D printing over the years has taken many forms. Known primarily for printing plastic and metal components, it is a technique that can produce more personalised parts for a range of applications and industries. 3D printing has become an area of interest in the medical industry, with 3D bioprinting gaining a lot of attention over the years. While bioprinting has gathered interest for printing actual biological tissues, more traditional 3D printing approaches can also be of use for building synthetic models.

Synthetic models using polymeric materials can be created for surgeons, with precise and personalised models being made of organs and anatomical areas of the body to practice on before the surgery takes place. For surgical training and preoperative planning, these models could become a vital tool for ensuring that surgeons achieve the best results and that patients have the best outcomes. As it stands, a lot of 3D printed models are too rigid to be used as a realistic model and cannot undergo repetitive resectioning (removing and sewing back on of surgical sections to then remove again), so their use has been limited. However, researchers have now created more realistic models using softer polymeric materials that show more promise.

The progression in 3D printing has been pivotal in medical applications, particularly for surgical training. A notable advancement is the creation of 3D printed liver models. These models are unique in their ability to not only mimic the liver's physical properties but also feature self-healing characteristics. This development is significant for surgeons, providing a more accurate and practical tool for preoperative planning and skill enhancement.

Turning to 3D Printing for Pre-surgery Models

3D printed models offer a way to explore the most optimal ways of performing surgery before the surgery takes place. This is called preoperative planning and helps to give the surgeon the best chance of success. However, existing models use commercially available printing materials that do not consider the textural feel and elastic modulus of the liver. This means that many models do not reflect the true deformation that the liver undergoes during respiration and from the surgical instruments.

3D printed surgical models should also have multiple uses where surgeons can experiment with different cutting planes and should be able to be stitched back together after cutting. Many models struggle with this due to the choice of printing materials, but using self-healing materials rather than the traditional rigid plastic materials that are currently used is seen as a way to combat this.

Self-healing mechanisms can be introduced to polymeric materials through dynamic covalent and non-covalent interactions in the polymer network when printed. Self-healing can be introduced chemically in a number of ways, such as through disulphide bonds, Diels-Alder coupling, boronic ester bonds, thiocarbamate bonds, and ionic bonds.

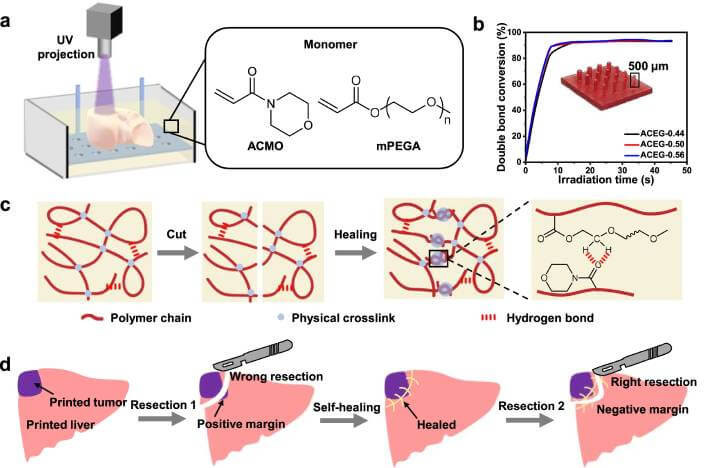

To better understand the innovative approach behind these self-healing 3D printed liver models, let's delve into the schematic representation of the process. Figure 1 illustrates the intricate process of 3D printing these elastomeric liver models, showcasing the sophisticated interplay of materials and technology that brings these models to life. This schematic not only highlights the technical prowess involved but also underscores the potential these models hold in revolutionizing surgical training and planning.

Fig. 1: Schematic of 3D printing self-healing elastomeric liver models

a. The configuration of Digital Light Processing (DLP) 3D printing, along with the molecular composition of the light-sensitive resin used. b. The reaction dynamics of the ACEG resin, varying according to the proportions of ACMO and mPEGA. An accompanying image illustrates the pillars printed in varying diameters. c. A diagrammatic representation of the self-repairing process inherent in the material. d. A detailed schematic depicting the self-healing elastomeric liver models, specifically designed for use in surgical training scenarios.

However, achieving a balance between stable crosslinking of the polymers when printed and their self-healing properties remains a challenge. A certain level of crosslinking is required to create a stable printed structure, but this can significantly reduce the self-healing properties of the finished model by inhibiting the motion of different polymer segments—as the crosslinking holds all the polymer chains more firmly in place.

Innovations in Self-Healing 3D Models

Addressing this issue, researchers have shifted towards a different strategy. By using physical crosslinking instead of chemical methods, they've successfully maintained the self-healing aspect of these 3D models. This technique allows the polymer chains greater mobility, crucial for the self-healing process, and aligns more closely with the mechanical properties of human organs.

Instead of chemically crosslinking the polymer chains, one of the promising options is to physically crosslink the polymer chains instead. Unlike covalently bonded crosslinked chains, physically crosslinked chains will migrate, diffuse, and entangle once disturbed, and these properties are the foundation for self-healing properties. No covalent crosslinkers also open the door to lower elastic moduli that can better mimic the properties of the body’s internal organs.

A New 3D Printed Liver Model that is More Realistic

Researchers have now used a stereolithographic 3D printing approach—known as digital light processing (DLP)—to print personalised liver models using physically crosslinked self-healing elastomers. The approach had a short printing time and allowed models to be created immediately after a CT examination had been completed for a patient—so that a personalised liver could be created based on the exact structure of the patient’s liver. This approach allows for preoperative planning to take place on the model before the actual surgery in clinical settings.

DLP was chosen as the printing process because it provides better printing stability and self-support for printing softer materials. The printing process used a photosensitive liquid resin as the printing material containing a rigid monomer known as 4-acryloylmorpholine (ACMO), a soft methoxy poly (ethylene glycol) acrylate (mPEGA) polymer, an Igracure 819 photo-initiator and a Sudan III light absorber. A patterned UV light is illuminated from the top of the printing platform and cures the polymers after printing and produces models with a liver-like softness.

The printed models had high self-healing efficiency and could support repetitive resectioning in trial-and-error approaches—where a section was cut, restitched, and then cut again at a slightly different place.

A preliminary clinical trial used 5 participants for preoperative planning for two different liver surgeries—local hepatectomy and left hemihepatectomy. The primary results of the clinical trial showed that vital vascular structures were avoided, and the required surgery margins could be achieved during the resectioning process. The personalised liver models were printed using the data acquired from the patients during CT scanning. The data was then developed into computed models via digital model construction before printing, and this provided the printing file for the DLP printer to use.

Under both liver conditions, it was found that the cutting and self-healing performance was similar and that the model itself could withstand various mechanical deformations—including stretching, twisting, and bending.

Clinical Validation and Real-World Application

One of the main considerations of any surgical model is how it compares to the real biological organ. To test this, the researchers took the left half of a liver specimen that was removed from a patient and compared it to the left half of the liver model. A left lateral lobectomy was performed on the biological specimen and the model, with the left hepatic vein exposed. The same external force was applied to both samples, and it was shown that both the biological specimen and printed model had similar deformation characteristics and that the exposed vein deformed in the same way as well.

The similarities between the biological specimen and the models showed that printed models can accurately simulate the deformation of the liver during surgery. This means that these accurate models could help to improve the safety of liver surgery via preoperative planning to remove tumours safely while avoiding important anatomical structures within the liver. Such models could not only help surgeons better plan their operations but could also be used to help junior doctors during their training stages by offering more realistic surgical environments to practice in.

Reference: