Write on! Penn State Researchers Develop Pencil-Drawn Sensors for Wearables

In The News | 17-02-2023 | By Robin Mitchell

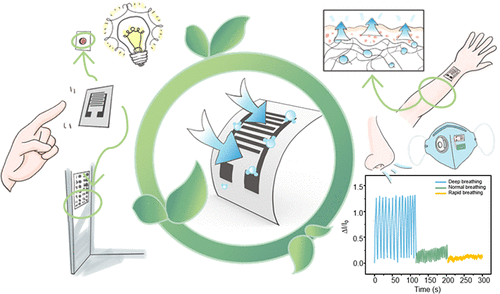

Recently, researchers from Penn State University published their work on smart wearables that can be used for remote medical detection. The sensors are fabricated using everyday household items such as graphite pencils, lead, and humidity detectors. These sensors can help detect medical issues, including diaper moisture and mask use, and can be connected with AI for more accurate analysis. The sensors can also be used for environmental detection, such as humidity levels. The research shows great promise in using low-cost materials for remote healthcare and could potentially revolutionise the field. What challenges do wearable sensors face, what did the researchers demonstrate, and how could such technology help the masses?

What challenges do wearable sensors face?

The field of wearable electronic devices is still in its infancy, and there are numerous reasons for this. One such reason is that electronic components are based on rigid solid materials, which means that trying to create devices that conform to the shape of the human body is extremely difficult. Furthermore, the human body moves around, bends, and twists, and this kind of movement will quickly cause fatigue in PCBs and components, resulting in cracking. Such wearable devices could be made ridged to protect them, but these would either be extremely limited in performance or uncomfortable to wear.

Flexible electronics exist, but they are either based on exotic materials that are hard to obtain or lack the capabilities of modern commercial electronics. For example, PragmatIC has demonstrated fully flexible ARM microcontrollers, but while these are great for product packaging, their high energy usage, physical size, and low performance make them unsuitable for wearable devices capable of making calls, sending messages, and browsing the internet.

Another challenge faced by wearable devices is the high cost of sensors. To create flexible electronics, the use of exotic materials is required, and these are also commonly expensive to produce. As such, the few devices that are manufactured in laboratory conditions are simply too costly to produce en masse. Overall, modern, flexible electronics are extremely difficult to manufacture, expensive and have poor performance characteristics.

Researchers develop wearable sensors drawn from pencil

Recognising the challenges faced by wearable sensors, researchers from Penn State University recently announced their development of new sensors that can be created using household items. The new sensors comprise of paper, sodium chloride, and drawn patterns using a pencil that can be utilised to detect humidity.

To manufacture the sensor, paper is first pre-treated with a sodium chloride solution that impregnates sodium and chlorine ions into the material. Once dried, the paper can then have graphite electrodes drawn on using a regular pencil. As the moisture content in the atmosphere increases, the paper absorbs more moisture, resulting in the free movement of ions. From there, electric signals can be measured across the electrodes, and the readings directly correlate to relative humidity. The resulting sensor is able to take measurements between 5.6% and 90% RH.

The use of paper and graphite not only makes the sensor flexible but also biodegradable. This means that sensors based on this technology can be composted using regular methods, thereby reducing environmental damage caused by disposable electronics. According to the researchers, the new sensor can be integrated into diapers to indicate when babies require changing, as well as masks to indicate breathing cycles.

How could such technology help the masses?

While the sensor could very well help with disposable electronics and medical diagnosis, the low-cost nature of the device makes it ideal for those in low-income areas. As the sensor can be manufactured from everyday household items, it can easily be replicated by anyone with access to paper, salt, and pencil lead (arguably the vast majority of the world). Therefore, anyone can bring smart functionality to masks, diapers, and other devices that may need to monitor moisture. Having access to a smartphone and open-source software could further reduce the barrier of entry to medical care as the sensor can be remotely monitored (likely via a low-cost interface).

Overall, the ability to create low-cost, disposable sensors with minimal environmental impact while providing useful data provides humanity with a major step towards affordable healthcare, even in the most remote places.