Researchers Develop Wearable Fabric With Integrated Solar Cells

Insights | 20-10-2022 | By Robin Mitchell

Recently, researchers have demonstrated a new wearable fabric that is able to generate as much as 400mW thanks to integrated solar cells. What challenges do wearable electronics face, what did the researchers present, and how is this demonstration a practical example of wearable electronics?

What challenges do wearable electronics face?

Even though researchers continue to make numerous advances in the field of wearable electronics, numerous technological challenges still prevent the widespread adoption of truly wearable electronics. Of course, some wearable gadgets currently exist, but these are almost always smartwatches and smart glasses. Furthermore, these devices are often bulky, and this can also make them uncomfortable to wear.

If a device is to be truly “wearable”, it should go unnoticed when worn or, at least, be comfortable to wear. But considering that modern electronics are inflexible and ridged, making comfortable electronics presents our first challenge, flexibility. Electronics that can flex and are able to move with the body organically (just like how clothing can flex and bend with motion) make them far more suitable for use in wearable technology.

The second challenge wearable electronics face is the need for a power source. Even if a device is entirely made with flexible components, current power sources such as batteries and solar cells are based on ridged technologies. This means that modern wearable designs rely on some solid power source that will undoubtedly be uncomfortable to wear. A solution around this is to use magnetic or RF coupling whereby a remote power source beams power to the device, but again, these act over short distances, which means that a power source still needs to be worn.

Thirdly, wearable devices must be practical; otherwise, their development has no commercial value. Researchers have already demonstrated flexible circuits and devices, but they are rarely more complex than a low-end microcontroller, which limits what they can do. This isn’t too much of a problem if the wearable is only being used for sensory reasons (such as medical data), but for wearable devices that intend to replace smartphones, this is a major challenge.

Researchers demonstrate wearable solar cells with a 400mW power capacity

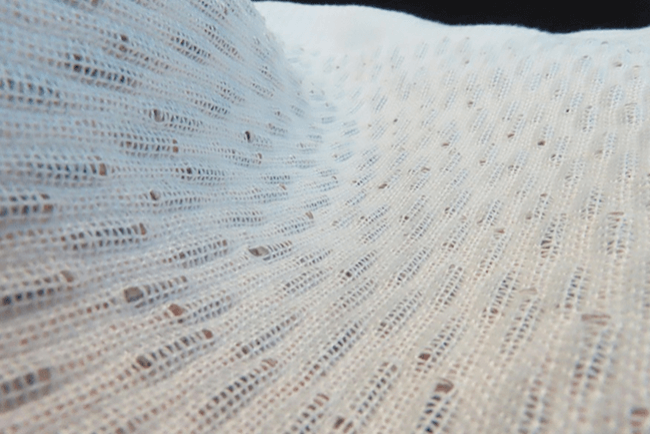

Recently, researchers from Nottingham Trent University demonstrated a new textile that integrates miniature solar cells, which are able to power small devices as well as charge a smartwatch or phone. Instead of creating a textile that is a natural solar cell, the researchers miniaturised solar cells and integrated these cells into a fabric.

Each cell has a dimension of 1.5mm x 5mm, and a total of 1200 cells were integrated into a piece of material. The test material provided 400mW of power in direct sunlight, and the cells themselves were embedded in a waterproof resin, allowing the textile to be washed at 40˚C with no sign of degradation to the power output. Furthermore, the wearer does not notice the solar cells integrated into the textile, which marks a major milestone in wearable technologies.

“Until now, very few people would have considered that their clothing or textiles products could be used for generating electricity. And the material which we have developed, for all intents and purposes, appears and behaves the same as any ordinary textile, as it can be scrunched up and washed in a machine. But hidden beneath the surface is a network of more than a thousand tiny photovoltaic cells which can harness the sun’s energy to charge personal devices. Electronic textiles really have the potential to change people’s relationship with technology, as this prototype shows how we could do away with charging many devices at the wall. This is an exciting development which builds on previous technologies we have made and illustrates how it can be scaled up to generate more power.” - Dr Hughes-Riley, of the university’s Advanced Textiles Research Group.

How does this announcement demonstrate practical wearable electronics?

While the device announced by the researchers is only for power generation, it presents exciting opportunities for engineers in the field of wearable electronics for two main reasons. The first is that the textile is capable of generating power from natural sunlight while being in a comfortable format. Furthermore, the textile can be washed, which immediately allows for the solar cells to be integrated into mainstream clothing such as jackets and coats. Power can be transmitted from such a textile either directly into a wearable device or through coupling to eliminate the need for wires.

But the second reason why this new textile demonstrates an important milestone is that it is able to generate a reasonable amount of power. While 400mW may not sound like a lot, it is more than enough to run low-energy processors, radio modules, and sensors. In fact, 400mW can easily result in a 5V source capable of providing up to 80mA. If this power is stored in a large capacitor over time, it can allow for a device to periodically perform a high-power operation such as cellular or Wi-Fi communication.

Of course, there are numerous challenges that the textile will have to solve, including its cost-effectiveness, ease of manufacture, and efficiency improvements. While 400mW is an excellent figure, this is in direct sunlight, which is not always available. But as the efficiency of solar cells increases while the energy usage of ICs decreases, it won’t be long before we see electronics integrated into materials.