3D Printing Lithium-Ion Batteries: Architectures and Gains

Insights | 08-09-2025 | By Robin Mitchell

Key Things to Know:

- Traditional roll-to-roll methods keep cells effectively 2D, limiting architecture-led gains in energy density, charge rate, and safety.

- 3D printing (FDM, DIW, SLA, BJ) enables tailored porosity and ion pathways, reducing inactive material and boosting performance.

- Early results are promising: uniform lithium deposition at 30 mAh·cm⁻²; ultrathick cathodes up to 5.16 mAh·cm⁻² and ~350 Wh·kg⁻¹.

- Key hurdles remain: printable conductive inks, post-processing, and speed, so near-term wins are in niche, high-precision designs while multi-material and AI-assisted formulations mature.

Lithium-ion batteries are the workhorse of modern energy storage, powering everything from handheld electronics to electric vehicles. Yet behind their sleek performance lies a surprisingly outdated manufacturing process, one that may be holding back the next wave of innovation.

In a recent review, researchers at North Minzu University explore how 3D printing could redefine lithium-ion battery production by enabling complex geometries and tailored microstructures once deemed impractical.

What limitations do traditional manufacturing methods face? How does additive manufacturing offer a path forward? And could 3D printing unlock the next generation of high-performance, customised energy storage solutions?

Challenges Facing Traditional Lithium-Ion Battery Manufacturing

Lithium-ion technology has earned its place as the dominant force in modern energy storage. From smartphones to grid-scale installations, it delivers exceptional energy density, works reliably across a vast range of sizes, and adapts well to almost any application. In short, it’s the all-rounder of the battery world.

However, for all its high-tech allure, lithium-ion manufacturing is still surprisingly old-school. Most cells are built using processes that wouldn’t look out of place in the earliest days of battery production: metal foils rolled into sheets, soaked in electrolyte, and sealed in rigid casings. The approach is simple, cost-effective, and proven, which explains its persistence. But it also means that the industry is, in some respects, stuck in a rut.

The problem isn’t that these methods don’t work; they clearly do. The issue is that they ignore emerging opportunities from materials science and microstructural engineering. Researchers are discovering new ways to arrange active materials in three dimensions, improve ion transport, and boost both energy and power density. Yet conventional roll-to-roll production doesn’t support these architectures without significant retooling. The result? Most commercial lithium-ion cells remain essentially two-dimensional in both structure and electrochemical operation.

That 2D limitation constrains performance potential and slows the adoption of designs that could revolutionise cycle life, charging speed, and safety. It’s a bit like designing a skyscraper but only being allowed to build bungalows, functional, yes, but far from the frontier of what’s possible.

3D Printing Opens New Pathways for Lithium-Ion Battery Design

A recent review from researchers at North Minzu University, published in ACS Omega, offers a deep dive into how additive manufacturing could upend lithium-ion battery (LIB) production. Led by Xiaofei Lou, Li Zhao, Yang Gao, and Xiaohui Nan, the team explores how 3D printing can address the structural and performance bottlenecks of traditional slurry-coating techniques.

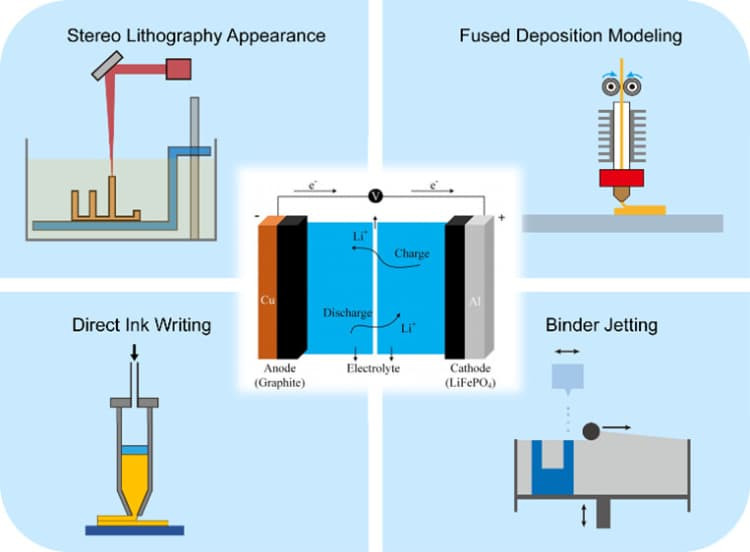

The core advantage lies in precision microstructuring. While conventional electrode fabrication treats geometry as an afterthought, 3D printing puts it front and centre. Techniques such as fused deposition modelling (FDM), direct ink writing (DIW), stereolithography (SLA), and binder jetting (BJ) allow manufacturers to design electrodes and electrolytes with finely tuned porosity, thickness, and ion pathways, unlocking higher energy density, improved cycle life, and reduced inactive material use.

To orient the reader, the schematic below highlights four additive manufacturing routes for lithium-ion batteries and where they act within the cell stack.

In practical terms, this means electrodes can be engineered for specific performance targets. Anodes, for instance, can incorporate porous carbon scaffolds or silicon–graphene composites to enhance lithium transport and suppress dendrite formation. One highlighted example, a nitrogen-doped carbon framework derived from zinc MOFs, achieved uniform lithium deposition with an area-specific capacity of 30 mAh·cm⁻², impressive numbers by any metric. Cathodes see similar gains: ultrathick LiCoO₂ and LiFePO₄ designs with engineered ion pathways have reached 5.16 mAh·cm⁻² and 350 Wh·kg⁻¹, respectively.

The review also points to advances in 3D-printed solid and quasi-solid electrolytes, where printable inks infused with UV-curable gels or ionic liquids offer both high ionic conductivity and improved interfacial stability, a key step toward commercially viable solid-state LIBs.

That’s the upside. The downside is that 3D printing still faces the usual suspects: conductive printable inks are tricky to formulate, post-processing (like thermal annealing) adds complexity, and current print speeds can’t match the volume demands of mass production. The researchers see near-term promise in niche applications, with broader adoption hinging on breakthroughs in multi-material printing and AI-assisted formulation design.

Could 3D Printing and Additive Manufacturing Be the Future of Battery Production?

Despite all the buzz, 3D printing isn’t about to overthrow traditional lithium-ion battery manufacturing anytime soon. The current roll-to-roll slurry coating methods are incredibly fast and cost-effective, which means they dominate simply because they work at scale and keep prices down. When you need millions of cells, speed and cost are king.

That said, additive manufacturing shines in areas where customisation and precision matter more than mass output. Think scientific robotic missions, space exploration, or highly specialised industrial uses. Here, you might want a battery with a unique shape, tailored energy profile, or integrated structural function, which is exactly the kind of scenario where 3D printing can deliver designs that conventional methods can’t touch.

If researchers can crack the code on printable conductive inks, streamline post-processing, and speed up print times, this technology could open doors to entirely new classes of batteries, ones that exploit 3D architectures for enhanced performance and novel functionalities. In other words, while 3D printing isn’t ready to mass-produce your next phone battery, it’s carving a niche that could lead to revolutionary breakthroughs down the line.

So yes, the future might be printed, but it’s a marathon, not a sprint. For now, traditional manufacturing holds the fort; additive manufacturing is quietly building the toolbox for tomorrow’s energy storage innovations.