IP67 Waterproof vs IP68: Understanding the Differences and Applications

Educational | 19-09-2023 | By Northern Connectors

Connectors often have to endure a range of elements, from dust and moisture to high or low temperatures and pressures. Whether it’s an outdoor environment or an indoor industrial environment, connectors must be engineered to the appropriate level of ingress protection.

When comparing IP67 waterproof and IP68 ratings, it is essential to understand their specific applications and limitations. This guide will help you determine the best rating for your needs.

While they don’t directly address the product’s temperature and pressure limits, ingress protection (IP) ratings provide information about the product’s level of resistance against solids and liquids.

The highest IP ratings promise complete protection against dust ingress and protection against water ingress under certain conditions, which are usually specified by the manufacturer.

IP67 vs IP68: Detailed Comparison

IP67 Waterproof Rating:

- Dustproof: Completely protected against dust ingress, ensuring no particles can enter the device.

- Waterproof: Capable of withstanding temporary immersion in water up to 1 meter in depth for 30 minutes without damaging the device.

- Ideal Applications:

- Outdoor Electronics: Devices that are frequently exposed to dust and occasional rain or splashes, such as outdoor lighting and garden tools.

- Handheld Devices: Smartphones, GPS units, and other handheld gadgets that might be briefly dropped in water.

- Industrial Equipment: Machinery and tools used in environments where dust and light water exposure are common, ensuring they remain functional even if temporarily submerged.

- Limitations:

- Not suitable for continuous underwater use or for depths greater than 1 meter.

- May not provide adequate protection in environments with high water pressure or turbulent water conditions.

IP68 Waterproof Rating:

- Dustproof: Offers the same high level of protection against dust as IP67, ensuring no dust ingress.

- Waterproof: Provides superior water resistance, capable of withstanding continuous immersion in water beyond 1 meter. The exact depth and duration are specified by the manufacturer and can vary, often up to 3 meters or more for 1 hour or longer.

- Ideal Applications:

- Underwater Cameras: Designed to operate efficiently under water for extended periods, making them perfect for underwater photography and videography.

- Marine Equipment: Devices used in marine environments, such as boat electronics and underwater sensors, which need to withstand continuous submersion.

- Heavy-Duty Industrial Equipment: Machinery used in harsh environments, including mining and construction, where prolonged exposure to water is expected.

- Limitations:

- Generally more expensive due to the advanced sealing and materials used to achieve higher waterproofing standards.

- Specific depth and time limits must be adhered to, as specified by the manufacturer, to ensure protection is maintained.

Technical Specifications:

- IP67 Rating:

- First Digit (6): Dust-tight, providing complete protection against dust ingress.

- Second Digit (7): Protection against temporary immersion in water up to 1 meter for 30 minutes.

- IP68 Rating:

- First Digit (6): Dust-tight, ensuring complete protection against dust ingress.

- Second Digit (8): Protection against continuous immersion in water beyond 1 meter, with specific depth and duration defined by the manufacturer.

Considerations for Choosing Between IP67 and IP68:

- Environmental Conditions: Assess the typical conditions the device will face, including dust levels and potential water exposure.

- Usage Duration: Determine whether the device will encounter temporary or continuous water immersion.

- Cost vs. Protection: Balance the need for higher protection with budget constraints, considering that IP68-rated devices are generally more expensive.

- Manufacturer Specifications: Always check the manufacturer’s guidelines for the specific depth and duration limits for IP68-rated devices to ensure they meet your requirements.

Decoding IP Ratings: Dust and Water Resistance

The IP code indicates a device's protection against water and dust. For example, an IP67-rated device is dust-resistant and can be submerged in 1 meter of freshwater for up to 30 minutes. This classification system, also known as the ingress protection code, is established under the international standard IEC 60529 by the International Electrotechnical Commission (IEC).

After all, there’s a difference between water-resistant and waterproof – splashproof doesn’t mean immersible, and getting this wrong could be a costly mistake.

IP67 and IP68 are among the top IP ratings. IP67 connectors can be submerged up to 1 meter for 30 minutes, while IP68 connectors can be immersed deeper than 1 meter for extended durations, with specifics detailed by the manufacturer.

This blog will explain the different levels of watertightness to help you choose the connector with the right IP rating for your application.

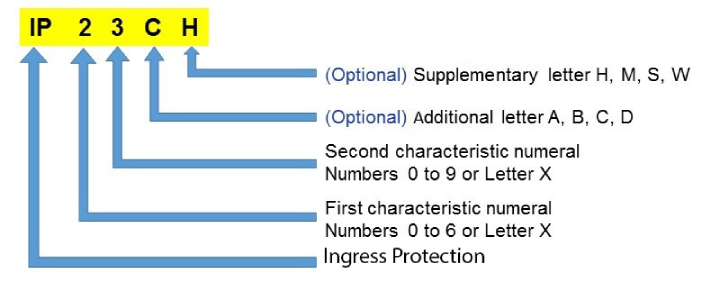

IP Code: Protection Levels Explained

The IP code defines protection levels against solids (0 for no protection to 6 for dust-tight) and liquids (0 for no protection against water to 9 for protection against high-pressure, high-temperature sprays). It's essential to note that the ratings for water ingress are not cumulative beyond IPX6. For instance, a device compliant with IPX7 (covering water immersion) might not necessarily comply with IPX5 or IPX6 (covering exposure to water jets).

To better understand the significance of IP ratings, it's essential to decode the IP code. The first digit indicates the level of protection the enclosure provides against solids, such as dust. The second digit, on the other hand, signifies the protection level against liquids, primarily water.

By Mahesh PathakI, IPX Codes Explanation Chart, CC BY-SA 4.0, Link

Origins of the IP Code

In the original IEC 60529 standard from 1976, the letters IP were used without a clear explanation, referred to as "characteristic letters". In subsequent editions of the standard, IP was clarified to represent "international protection" in both French and English. The abbreviation might be a combination of the English word "ingress" and the French word "pénétration" both signifying ingress. However, the exact origin would require a deep dive into the 1970s standardisation, a challenging task since many experts from that era are likely retired or no longer alive.

Deciphering the IP Code: Dust and Water Ratings

The level of protection against water ingress can vary, which is why manufacturers prefer the term ‘watertight’ – as their products are not infinitely waterproof but can resist it for some time.

It's essential to understand that the IP rating system, established by the International Electrotechnical Commission (IEC), serves as a ruggedness scale. This system provides a clear indication of a device's ability to withstand environmental factors, particularly water and dust. In fact, studies have shown that up to 20% of all phone damage results from immersion or contact with liquids. Hence, understanding these ratings becomes crucial for both manufacturers and consumers.

IP67 Connectors: Dust-Proof and Temporary Water Immersion

As the first letter of the rating applies to solids, the 6 in IP67 is the highest rating of dust protection, completely preventing dust and other particles from getting inside the equipment.

The second letter applies to water ingress, and 7 is the lowest rating that offers a level of water tightness – a rating of 6, in this case, means the product would be protected against jets of water but cannot actually be submerged in water without ingress occurring.

IP67 generally means that the product can withstand immersion in water at depths of up to 1 metre for up to 30 minutes, with no harmful effects from limited ingress.

This is suitable for brief and temporary submersion but not for a scenario where connections would have to run underwater or may be immersed in water for longer periods of time.

If your application doesn’t require immersion, but there is a potential risk of this occurring, then IP67 products offer peace of mind that ingress won’t immediately occur.

However, if your application requires connectors that can withstand immersion for longer than 30 minutes at depths greater than 1 metre, an IP67 rating will not be sufficient.

Technical Specifications of IP67 Rating:

- Dustproof: 6 (completely protected against dust)

- Water Protection: 7 (protected against temporary water immersion up to 1 meter for 30 minutes)

IP68 Connectors: Dust-Proof and Prolonged Water Immersion

The next level up has the same top rating of 6 for dust protection, meaning IP68 products are also completely sealed against ingress from dust and particulates.

The difference is that IP68 has a higher water ingress rating, which means a product with this rating can be immersed in water deeper than 1 metre for a continuous period.

The manufacturer will test and specify the maximum depths and length of time that the ingress protection will hold depending on the product’s intended use, but IP68 typically applies between 1–2 metres deep for longer than 30 minutes.

In any case, harmful levels of water ingress should not be possible when immersed continuously under the conditions specified by the manufacturer, which will be more severe than IP67’s limits.

Technical Specifications of IP68 Rating:

- Dustproof: 6 (completely protected against dust)

- Water Protection: 8 (protected against prolonged water immersion beyond 1 meter, specifics defined by the manufacturer)

Determinants of IP68 Connector Effectiveness

The manufacturer may also specify factors such as temperature fluctuation and flow rate, which may affect the duration of effective ingress protection.

If you require connectors that can withstand high levels of pressure in addition to immersion in water for limited periods, then you may need to upgrade from IP68 to IP69K.

This is the highest possible IP rating for watertightness, promising protection against ingress from high-pressure and high-temperature jets, which are normally used in industrial cleaning.

It's worth noting that while IP67 and IP68 are among the most sought-after ratings, there are other IP ratings available, each designed for specific conditions. For instance, IP66-rated connectors are dust-tight and include a vacuum seal, ensuring protection against particulates and any airflow. They are also waterproof, safeguarding against direct high-pressure jets. Understanding the nuances of each IP rating can significantly influence the success and longevity of your project.

Choosing Between IP67 and IP68 Connectors

They are both suitable for environments with risks of spraying or splashing, but your choice should be guided by the manufacturer-set limitations for actual immersion.

Where possible, these should include details of the product’s pressure and temperature resistance, as well as corrosion resistance, as most IP ratings apply to freshwater.

It’s best to treat an IP rating as an indication rather than a guarantee, as they don’t account for all scenarios, and opt for a higher rating if you aren’t sure whether a lower rating will be sufficient.

It’s also important to remember that some parts only achieve the assigned IP rating when installed in a particular way, usually requiring all parts to have the same IP rating or higher.

If necessary, you can ask the experts – Northern Connectors are trusted UK suppliers of a selection of watertight connectors and accessories from leading international manufacturers and would be happy to offer guidance before you place an order.

Benefits and Limitations of IP67 and IP68

Benefits of IP67:

- Effective Dust Protection: Provides complete protection against dust ingress, ensuring device longevity in dusty environments.

- Temporary Water Resistance: Capable of withstanding temporary immersion in water up to 1 meter for 30 minutes, suitable for devices that might encounter brief submersion.

- Cost-Effective: Generally more affordable than IP68-rated devices, offering a practical solution for environments with occasional water exposure.

Limitations of IP67:

- Not for Prolonged Immersion: Not suitable for continuous or prolonged immersion in water, limiting its use in more demanding underwater applications.

- Limited Water Depth: Only effective up to 1 meter depth, which may not be sufficient for certain applications requiring greater water resistance.

Benefits of IP68:

- Enhanced Water Resistance: Provides superior protection for continuous immersion in water beyond 1 meter, ideal for underwater and marine applications.

- Long-Term Durability: Designed to withstand harsher and more prolonged water exposure, ensuring reliability in challenging environments.

- Versatility: Suitable for a wide range of demanding applications, including industrial, marine, and heavy-duty equipment.

Limitations of IP68:

- Higher Cost: Generally more expensive due to advanced sealing techniques and materials used to achieve higher protection levels.

- Specific Testing Requirements: The effectiveness of the protection can vary depending on the manufacturer's specifications, requiring careful consideration of product details.

Practical Applications of IP67 and IP68 Ratings

IP67 Applications:

- Outdoor Electronics: Ideal for devices such as outdoor lighting, garden tools, and security cameras that are frequently exposed to dust and occasional rain or splashes. IP67 ensures they remain functional even if temporarily submerged in water.

- Handheld Devices: Perfect for smartphones, GPS units, and other handheld gadgets that might be briefly dropped in water. The IP67 rating ensures these devices are protected from dust and can withstand short-term immersion.

- Industrial Equipment: Suitable for machinery and tools used in environments where dust and light water exposure are common. This rating ensures they remain operational even if temporarily submerged in water.

IP68 Applications:

- Underwater Cameras: Designed to operate efficiently under water for extended periods, making them perfect for underwater photography and videography. The IP68 rating ensures these devices can withstand prolonged immersion at specified depths.

- Marine Equipment: Ideal for devices used in marine environments, such as boat electronics and underwater sensors, which need to withstand continuous submersion. IP68 provides peace of mind for prolonged underwater use.

- Heavy-Duty Industrial Equipment: Suitable for machinery used in harsh environments, including mining and construction, where prolonged exposure to water is expected. The IP68 rating ensures these devices can withstand the rigors of continuous immersion and high-pressure water exposure.

In Summary

IP ratings play a crucial role in determining the resilience of connectors against environmental factors like dust and water. Understanding the nuances between ratings like IP67 and IP68 can make a significant difference in the longevity and efficiency of your equipment. Always consult with experts and manufacturers to ensure you're making the right choice for your specific needs.

References