Perovskite Solar Cells: Efficiency vs Environmental Risks

Insights | 17-02-2023 | By Paul Whytock

This article was updated on July 14, 2025, to reflect the latest advancements in perovskite solar cell technology, including recent efficiency records, durability improvements, and emerging lead mitigation strategies.

Key Takeaways:

- High Efficiency, But Fragile: Perovskite solar cells (PSCs) offer impressive power conversion rates—up to 32% in tandem configurations—but suffer from poor long-term durability and sensitivity to light, heat, and voltage.

- Environmental Concerns: PSCs contain toxic materials like lead, posing risks during manufacturing, usage, and disposal unless safely contained.

- Production Challenges: Scaling PSCs for mass production remains difficult due to material costs, manufacturing limitations, and issues like current-voltage hysteresis.

- Ongoing Innovation: Researchers are developing solutions such as lead-stabilising salts, nanotextures, and hybrid architectures to enhance PSC stability, efficiency, and safety.

Perovskite solar cell technology is emerging as the next-generation solution for improving solar panel efficiency. However, this promising innovation faces significant barriers, including scalability, stability, and environmental safety.

So, on the one hand, we have what can be considered a positive ecological option when it comes to creating solar energy efficiently, but on the other hand, it’s definitely not green regarding its material composition and how they are disposed of at the end of its product life.

Add to those negative elements the fact that PSCs can demonstrate current-voltage hysteresis, which can seriously impact the operating performance of the cell.

However, PSCs that are free of hysteresis problems may be possible, but only if suitable manufacturing processes are developed which will avoid this operational weakness.

Why Perovskite Solar Cells Matter

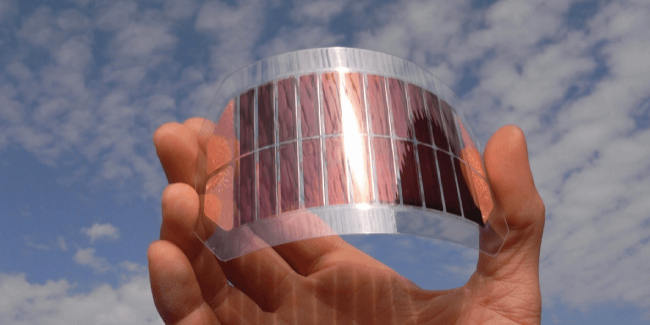

Perovskite solar cells are rapidly gaining attention as a transformative technology in the field of photovoltaics. Unlike traditional silicon-based solar panels, perovskite materials offer high absorption coefficients, tunable bandgaps, and compatibility with low-cost manufacturing methods such as spin coating and inkjet printing. These advantages make them suitable for a wide range of applications, from flexible wearable panels to building-integrated photovoltaics (BIPV).

What makes perovskite solar cells especially significant is their potential to outperform silicon in terms of power conversion efficiency. Tandem perovskite-silicon solar cells have already achieved lab-record efficiencies exceeding 32%, with theoretical limits even higher. This performance gain, combined with lightweight and adaptable form factors, positions perovskite solar panels as ideal candidates for the next generation of solar energy systems.

Moreover, the simplicity of the perovskite crystal structure allows for rapid advancements in material chemistry, enabling researchers to optimise performance characteristics quickly. With growing interest in sustainable energy and the need to reduce dependency on fossil fuels, the development of scalable and stable perovskite technologies could redefine the solar industry.

Perovskite Solar Cells: Efficiency vs Scale

In addition to that, production processes need to be implemented that will adequately meet high-volume mass production requirements; otherwise, expensive PSCs will not achieve the economy of scale necessary to make them a financially attractive option. Take, for example, the use of indium tin oxide in PSCs. It may well have very high conductivity, which is desirable, but it’s a rare material costing 1850€/Kg, and indium is prone to cracking.

So manufacturers of PSCs have a number of hurdles to clear, and these include the toxic substances used, material fluctuations and the aforementioned hysteresis problems. Current production methods are prone to creating PSCs that are delicate and not sufficiently resilient for long-term applications.

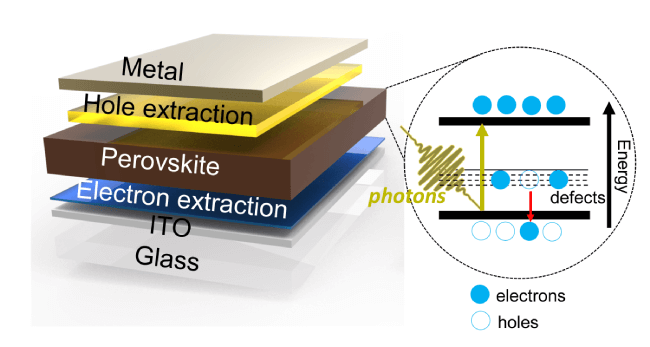

A schematic of a perovskite solar cell showing that the perovskite is nestled in the centre of the cell. The absorption of solar light causes the electrons to jump to higher energy levels, leaving the holes behind. Further separation of the electrons and the holes results in the generation of a current. The existence of defects that might trap the electrons or the holes can cause the whole solar cell to lose efficiency.

Lots of work is going on to correct these deficiencies, and of particular focus are the ways in which the power-generating efficiencies of PSCs can be enhanced.

Researchers at Helmholtz Zentrum Berlin (HZB) have been able to demonstrate the conversion of 32% of solar radiation into electrical energy using PSC technology.

The team used a tandem cell technology consisting of a bottom cell made of silicon, which is typically used in commercial solar panels, along with a thin top cell made of perovskite.

Many believe this cell technology is commercially viable. While the top cell uses blue-light components, the bottom cell converts the red and near-infrared components of the spectrum. Different thin layers help to gain maximum benefit from the light and cut electrical losses.

Tandem designs using perovskite solar panels and silicon are at the forefront of solar technology, offering unmatched conversion potential.

Reducing Parasitic Loss in Perovskite Solar Cells

Research teams have also introduced a nano-optical structure made of a corrugated nano-texture on the silicon surface that minimises reflection losses and ensures a more uniform perovskite film formation. In addition, a dielectric buffer layer on the reverse of the silicon minimises parasitic absorption at close to infrared wavelengths.

PSCs also have the ability to react to different colours in the solar spectrum by changing the material composition. This flexibility allows perovskites to be combined with another, differently-tuned absorption material to create more power from the same device. This is known as a tandem device architecture.

Perovskite Solar Cell Degradation: A Core Challenge

So there is no doubt that PSCs have high efficiencies when converting solar energy into electricity, but what about the durability issues?

PSCs' durability and operational stability are not comparable to established photovoltaic (PV) technologies. One failing is that they can deteriorate when exposed to light, which is a fundamental flaw when considering their role. The cells also do not tolerate extended exposure to heat or applied voltage. This degradation is a critical limitation for perovskite-based photovoltaics, especially in outdoor or commercial applications.

These are problems, but alternative manufacturing and encapsulation materials of varying formulations are being developed that will definitely inhibit current product degradation tendencies.

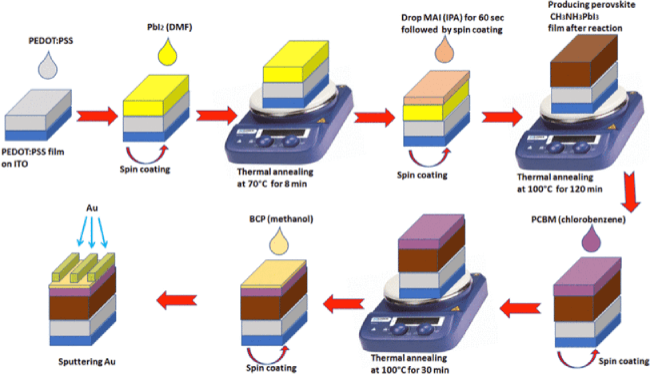

The fabrication process of perovskite solar cells (CH3NH3PbI3) using a two-step static spin coating technique

The Solar Energy Technologies Office stipulates that PSC-based products should have a minimum life span of 20 years. It also encourages the development of standardised testing and product evaluation procedures to ensure the performance of different PSC developments can be fairly compared.

Turning to the previously mentioned environmental concerns regarding PSCs, the main worry is the lead used in their construction.

This raises several concerns. Firstly consumers are increasingly wary of using products that contain toxic materials. Secondly, there is the risk to people involved in the manufacturing of panels that use PSC technology, and finally, there is the problem of their disposable at end-of-life.

The difficulty is that the lead used in PSCs can dissolve in water, which becomes an environmental problem when a solar panel containing PSCs breaks and then gets rained upon.

Locking in the Lead

To prevent the lead from becoming a hazard, it must be contained, and this has encouraged considerable research to solve the problem. However, trials of developing PSCs with lead-free non-water-soluble alternatives have failed to provide adequate power conversion efficiencies.

One ingenious solution to this problem could be the use of

a transparent phosphate salt. This will not affect the conversion efficiencies of a solar panel, but if the panel breaks, the salt interacts with the lead to create a water-insoluble compound that cannot leak out of the panel

So, research is identifying alternative materials, but for any to be acceptable, they must create cells that have the same high level of power conversion efficiency and, importantly, do not exacerbate the hysteresis problem. It also has to be price-competitive.

Researchers believe customised nanotextures can help to improve perovskite semiconductor materials on diverse levels. These results are not only valuable for tandem solar cells made of perovskite and silicon but also for perovskite-based light-emitting diodes.

While perovskite solar cells remain the most viable high-efficiency option, efforts toward lead-free perovskite materials continue to accelerate.

So there is no doubt that PSC technology is the way forward in generating electricity from solar energy, and it will surpass current silicon-based options. However, lurking in the background is the possibility of organically-based solar cells.

These promise advantages such as being inexpensive and flexible but cannot compete with PSCs when it comes to power conversion...well, not yet, anyway.