Reconfigurable Flexible CMOS Circuits Advance Modular Design

Insights | 19-06-2025 | By Robin Mitchell

Key Takeaways:

- Rice University researchers have developed reconfigurable carbon nanotube transistors capable of switching between p-type and n-type behaviours.

- These polarity-configurable thin-film transistors (PC-TFTs) enable flexible, adaptive CMOS circuits suitable for wearables, medical devices, and more.

- While post-manufacture configurability is a major advance, runtime reprogrammability remains a key challenge for edge AI and secure systems.

- Future concepts combining electrostatic doping and floating gate technology may enable fully reprogrammable hardware architectures.

While software continues to evolve at an astonishing pace, thanks to its inherently flexible and digital nature, hardware remains rooted in the physical world — unyielding and, once manufactured, largely immutable. This fundamental contrast has long shaped the dynamics of technology development, where code can be recompiled and redeployed in seconds, but a flawed circuit board is destined for landfill.

Now, researchers at Rice University have taken a significant step toward bridging this divide with a new class of reconfigurable carbon nanotube transistors. Could this innovation signal a shift in how we approach hardware design?

The Fixed Nature of Hardware

One industry that has seen truly explosive growth over the past few decades is software. From banking systems and mobile apps to spacecraft and smart fridges, software is everywhere, adapting and evolving at a breakneck pace. It's not just because humans are clever - it's because software, by its very nature, is digital. You can rewrite it, fork it, patch it, update it, and ship it globally in seconds. That's something no other discipline in engineering can compete with.

This ability to change code on the fly has given birth to entire movements, with open-source software being the poster child. Think about it: a few lines of code posted online can be picked up, modified, and redistributed by anyone, anywhere. This freedom has powered collaboration on a global scale and led to some of the most robust and widely used tools in the world, often built by unpaid contributors who just want to fix a problem or build something better. Try doing that with a PCB.

The Physical Limits of Hardware Innovation

Now, let's look at the other side of the coin - hardware. Good old, reliable, unforgiving hardware. Unlike software, hardware is fixed. Once manufactured, that's it. You're not pushing a firmware patch to a blown capacitor or a bad batch of solder joints. Hardware is bound by the physical world, and as much as engineers might dream of infinite configurability, the laws of physics and manufacturing constraints don't care about your deadlines or changing requirements.

Sure, there are some exceptions. FPGAs give us a taste of reconfigurability - effectively letting us "compile" new hardware behaviours without swapping out a chip. But even then, you're still working within predefined logic blocks on a fixed silicon die. You're not changing the hardware itself; you're just rewiring the playground fence.

This rigidity presents some very real challenges. For starters, hardware becomes obsolete faster than most people expect. A chipset from five years ago might not just be old - it might be impossible to integrate into modern systems. Then there are hardware bugs. If a design flaw sneaks past validation and ends up in production, you're out of luck. There's no patching a bad trace or an incorrect voltage rail. And let's not forget the environmental cost: outdated and unrepairable hardware leads to growing mountains of e-waste, much of which is still functional but no longer supported.

The truth is that hardware's physical permanence is both its strength and its greatest weakness. You can't argue with electrons and materials - they do what they're told, no more, no less. That's why designing hardware requires foresight, rigour, and a healthy respect for the real world. In a time when everyone's obsessed with "moving fast and breaking things," hardware reminds us that some things, once broken, stay broken.

Researchers Create Reconfigurable Transistors

A team of researchers from Rice University has made a breakthrough in the field of flexible electronics with the development of reconfigurable complementary circuits based on polarity-configurable carbon nanotube transistors. The research, led by Lian-Mao Peng, was published in the journal Nature Electronics and outlines a new method for configuring the polarity of field-effect transistors using electrostatic doping.

According to the study published in ACS Nano, this approach leverages an ambipolar charge transport mechanism within carbon nanotubes, allowing the same device to behave as either an electron or hole conductor depending on the doping configuration. This attribute helps reduce circuit complexity and physical footprint — critical for next-generation flexible systems.

Ambipolar Transport and Transistor Polarity Control

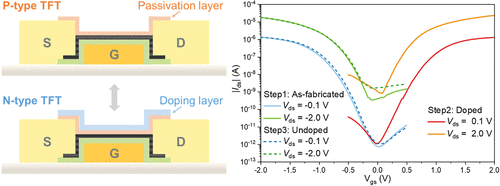

The researchers developed a strategy for creating carbon nanotube transitors that can function as both p-type and n-type devices. The devices, which are referred to as polarity-configurable thin-film transistors (PC-TFTs), can be switched between the two polarities by applying and removing a layer of polymer doping. This method allows for the creation of complementary metal-oxide-semiconductor (CMOS) circuits that can be reconfigured to perform different functions.

Illustration of a polarity-configurable thin-film transistor (TFT) capable of switching between P-type and N-type modes via selective doping. The accompanying graph shows the drain current (I<sub>ds</sub>) versus gate voltage (V<sub>gs</sub>) characteristics across different doping stages, demonstrating the device’s reconfigurability.

The flexibility of PC-TFTs is particularly notable in environments where post-manufacture adaptability is valuable. By fine-tuning transistor polarity at the system integration stage, manufacturers could theoretically cut down production variants, enabling mass customisation without redesigning hardware layouts — a potential game changer for modular electronics and prototyping workflows.

From Concept to Circuit: Demonstrating Practical Applications

The researchers first demonstrated the capabilities of their PC-TFTs by constructing a CMOS inverter that can operate with a rail-to-rain output and a voltage gain exceeding 40 dB. They also constructed basic circuit components such as diodes, rectifiers, and gates that can be reconfigured with different functionalities.

This ability to repurpose logic gates within a static substrate architecture introduces new potential in fault tolerance and longevity. Should a part of the circuit fail or degrade over time, its function could be rerouted or adjusted through configuration — a paradigm shift in how engineers consider wear and obsolescence in hardware.

Programmable Logic for Adaptive and Secure Electronics

To further demonstrate the potential of their reconfigurable CMOS circuits, the researchers designed a reconfigurable circuit module that can be programmed to perform four different functions: NAND, NOR, XOR, or XNOR. This module can serve as a building block for more complex reconfigurable circuits, which could have applications in hardware security and adaptive monitoring.

Security researchers have long explored polymorphic hardware as a method of combating hardware-based attacks. The dynamic nature of these reconfigurable modules, combined with the unpredictable logic paths they enable, may add a layer of obfuscation that makes reverse-engineering significantly more difficult, aligning with the broader shift toward secure-by-design principles.

Expanding the Application Space of Reconfigurable Hardware

The researchers believe that their reconfigurable CMOS circuits have the potential to be used in a wide range of applications, including wearable electronics, flexible displays, and medical devices. The use of reconfigurable circuits could also enable the development of more complex electronic systems that can adapt to changing environments and tasks.

In medical device development, such adaptability could allow a single embedded system to handle diverse diagnostic tasks or respond to physiological changes in real-time. Likewise, wearable technology stands to benefit from reconfigurable logic that supports firmware-level updates without needing new silicon — effectively extending product lifecycles in cost-sensitive markets.

Could These Reconfigurable Transistors Be the Future of CMOS?

What the researchers have pulled off here is, without a doubt, impressive. They've taken the foundational building block of digital electronics - the humble transistor - and given it a new layer of flexibility. The ability to configure individual transistor polarity after fabrication is no small feat. It hands engineers a level of control previously reserved for simulation and dreams.

While this approach using carbon nanotubes and a reversible doping polymer is clever, it's not electrically programmable, and that's the sticking point. The device configuration depends on the physical application and removal of a doping layer - a process that, while reversible, is not something you can trigger on demand from within a circuit. Once a device is "committed" to P-type or N-type, you're still dealing with fixed functionality in practice. In other words, it's not truly reprogrammable hardware - it's just configurable hardware with an asterisk.

This means that although the method offers flexibility during development or production, it doesn't solve the deeper issue of runtime reconfigurability - something modern applications in adaptive computing, edge AI, and hardware security are increasingly demanding. These transistors still fall into the trap that plagues all traditional hardware: once set, they stay that way.

Towards Electrically Reprogrammable Transistor Architectures

Now, here's where things could get interesting. If this electrostatic doping effect could be harnessed through a floating gate mechanism - the same principle that allows flash memory cells to retain charge - we might be looking at the early signs of a game changer. Floating gates trap electric charges to alter a device's behaviour without physically modifying it. Marrying that concept with the polarity configurability seen here could, in theory, lead to a transistor that can be electrically programmed and reprogrammed, potentially many times over.

That would fundamentally shift how we build logic blocks, memory, and maybe even entire chips. Suddenly, FPGAs and microcontrollers could share the same silicon substrate with no hard line between them. Hardware would become more like firmware - editable, updatable, and adaptive.

We're not there yet. But this research is a strong step in that direction. It's not the final product, but it's a proof-of-concept worth keeping a close eye on. If someone figures out how to bring electrical programmability to these reconfigurable devices, then yes - this could very well be the future of CMOS. Until then, it's a promising, but limited, innovation.

Read More:

How Vertical CMOS Stacking Will Continue to Shrink Devices

Explores how 3D integration and stacking in CMOS design is driving miniaturisation in consumer and industrial electronics.

Sony’s 2-Layer CMOS Pixel Sensors Increase Light Sensitivity

Details Sony's breakthrough in stacked sensor design, separating photodiodes and transistors for enhanced image performance.

Balancing CCD and CMOS Technologies in Industrial Imaging

Compares CCD and CMOS sensor architectures and their trade-offs in applications like machine vision and scientific instrumentation.

New Ultra-Thin Capacitor Developed for Improved Energy Efficiency

Highlights recent progress in capacitor miniaturisation, with implications for power delivery in compact and mobile devices.