Phononic Metamaterials: Pioneering Green Tech Solutions

Insights | 14-02-2024 | By Robin Mitchell

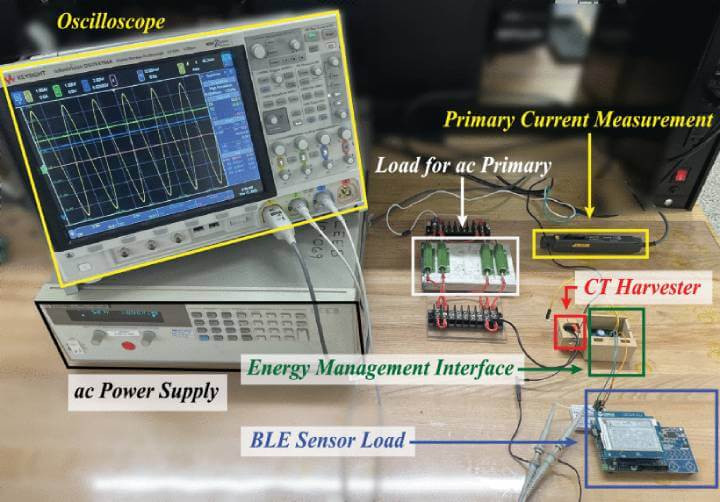

Captioned image of the test configuration, showing the split-core current transformer (CT) harvester attached to an AC power line, which supplies power to the energy management interface and the Bluetooth Low Energy (BLE) sensor kit.

Key things to know:

- Revolutionary energy-harvesting device taps into ambient magnetic fields to power sensors, eliminating the need for batteries.

- MIT researchers' development leverages supercapacitors for long-term, maintenance-free sensor operation, promising decades of service.

- Technology offers a sustainable, cost-effective solution for sensor deployment in hard-to-reach or maintenance-intensive environments.

- Potential applications include upgrading naval ships, showcasing the device's versatility and minimal impact on existing systems.

Recognising the difficulty of providing power to sensors in critical applications, researchers recently demonstrated a new energy-harvesting device that is capable of extracting stray magnetic fields from motors and other powered devices. What challenges can sensors face in deployment, what did the researchers develop, and what makes this solution particularly useful?

What challenges can sensors face during deployment?

Over the next decade, the number of sensors being deployed globally will be unlike anything seen in the tech industry since the first transistors were developed. The ability to utilise low amounts of energy, wirelessly connect to internet services, and stream real-time data to cloud systems allows for all kinds of applications, ranging from basic environmental management all the way to advanced AIs, capable of making decisions on the fly.

While the deployment of countless sensors will undoubtedly help advanced technology immensely, the physical act of setting up such sensors, powering them, and performing maintenance introduces numerous challenges.

The need for a power source means that installed sensors must either be located near an outlet, rely on internal batteries, or utilise passive energy sources such as wind and solar. Outlet power sources are by far the best solution, as they are permanent and always available, but outlets are often hard to find, and installing new outlets can be extraordinarily expensive.

Internal batteries can be ideal for devices in remote areas, and low-energy communication technologies such as LoRa can be used to extend battery life. However, as all batteries eventually run out, sensors would need to be located, taken out of service, have their batteries replaced, and put back into service. For a handful of sensors, this isn’t too much of an issue, but for thousands scattered across a wide area, this task can be extremely difficult.

Passive energy sources such as solar and wind can be used to power IoT devices in remote areas for extended periods of time. However, the unreliability of renewable energies combined with the need for an energy storage device can make them unsuitable, especially in environments where these energy sources do not exist (such as in a ship or in an industrial facility).

Researchers create passive energy harvester for sensor devices

Recognising the challenges faced with sensor deployment, a team of researchers from MIT have demonstrated a new energy-harvesting PCB that is capable of powering sensors and reporting information utilising the magnetic energy from power wires. While numerous reports are claiming that the device draws energy from “thin air”, the reality is that the device is actually stealing a minute amount of power from wires used to power large devices, such as motors, and using that stolen power to enable real-time sensors to operate.

The device developed by MIT researchers exemplifies a significant stride in sensor technology, leveraging ambient magnetic fields to power sensors autonomously. This innovation not only circumvents the limitations posed by battery dependency but also introduces a sustainable, maintenance-free solution for sensor deployment. The ability of these sensors to harness energy from their surroundings without direct electrical connections presents a novel approach to overcoming the challenges of sensor power supply in remote or inaccessible locations.

While this device may seem unimportant at first (as there is no such thing as free energy), the potential in the device is not in its ability to extract magnetic energy but that it eliminates the need for sensors to have internal batteries or be reliant on a dedicated power source.

The device itself takes advantage of magnetic coupling with a ferrite ring that clamps around a wire carrying an electric current and converts the changing magnetic field into a voltage source. Instead of utilising batteries for storage, the device utilises supercapacitors, which eliminates the need for maintenance once installed, and the lack of degradation means that the lifespan of such sensors is in then decades and not years.

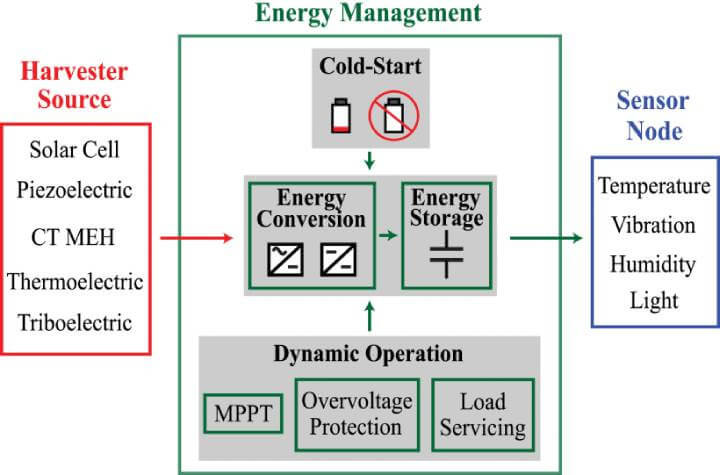

Fig 1 illustrates the key components of the self-powered sensor system, showcasing how it interfaces between a harvester source and sensor node for efficient energy management and sustainability.

Fig. 1 illustrates how a self-powered system effectively bridges the gap between a harvesting source and a sensor node. It highlights essential design elements such as cold-start circuitry for initial activation, efficient energy conversion and storage mechanisms, dynamic algorithms for Maximum Power Point Tracking (MPPT) and energy optimization, overvoltage protection, and the overall management of the sensor node.

Fig. 1 illustrates how a self-powered system effectively bridges the gap between a harvesting source and a sensor node. It highlights essential design elements such as cold-start circuitry for initial activation, efficient energy conversion and storage mechanisms, dynamic algorithms for Maximum Power Point Tracking (MPPT) and energy optimization, overvoltage protection, and the overall management of the sensor node.

Supercapacitors: Enhancing Sensor Longevity and Sustainability

Further emphasising the practicality of this technology, the use of supercapacitors for energy storage within the MIT prototype underlines a pivotal shift towards more durable and reliable sensor operations. Supercapacitors, known for their quick charging times and extensive lifespan, offer a robust alternative to batteries. This choice not only mitigates the need for frequent maintenance but also aligns with environmental sustainability by reducing waste associated with battery disposal. The integration of supercapacitors signifies a forward-thinking approach to extending the operational life of sensors while maintaining their efficiency and effectiveness in data collection.

One potential application that has taken great interest in the new device is the US Navy, which believes that the technology could be used to help upgrade ships. Due to the severe restrictions placed on hardware in Naval ships, adding new sensors is extremely difficult, if not impossible, as these sensors would require reliable power sources (thus, needing to splice wires and access critical infrastructure).

If the new energy harvest device from MIT is used instead, then it becomes possible to simply clamp sensors around pre-existing wires, having minimal impact on their performance. From there, these sensors could then provide invaluable data, such as real-time vibration and temperature readings for motors, engines, and other equipment.

Could such devices become practical in the future?

In order for these energy harvesters to work, they require power lines carrying AC voltages as opposed to DC voltages, as a magnetic field alone cannot generate electricity. This limits their potential deployment, but considering that most applications requiring IoT sensors will likely be close to a source of AC power, this would only affect rare cases where DC is being distributed at a distance.

The lack of a need for power taps, large transformers, and power rectification stages also makes installation trivial, and the ability to simply clip over a power line and start operating means that large sensor deployments can be done at speed. Furthermore, as these devices do not interfere with an installation, safety-critical applications are not affected by their use, thus allowing for improvements as new sensing technologies become available without making any fundamental changes to the system as a whole.

The innovative design and application of the energy-harvesting sensor by the MIT team underscore the potential of self-powered devices in transforming sensor deployment across various industries. By eliminating the need for external power sources or battery replacements, these sensors pave the way for more sustainable, cost-effective, and scalable solutions in monitoring and data collection. The adaptability of such technology to harness ambient energy sources reflects a significant advancement in making IoT devices more autonomous and environmentally friendly.

Of course, the device is still in its prototyping stage, and the small amount of energy that it can harvest is far from ideal for everyday use. However, with time, the researchers will be able to improve the characteristics of the energy harvester, potentially giving engineers a new method for powering future devices.