The Environmental Impact of EV Batteries and the Search for Alternatives

Environment | 13-07-2023 | By Paul Whytock

We all know electric vehicles (EVs) will dramatically help to improve the quality of the air we breathe, and we all know how important that is. Take, for example, just one statistic. Research in the US estimates that over 7000 Americans a year die as a direct result of vehicle emissions in the atmosphere.

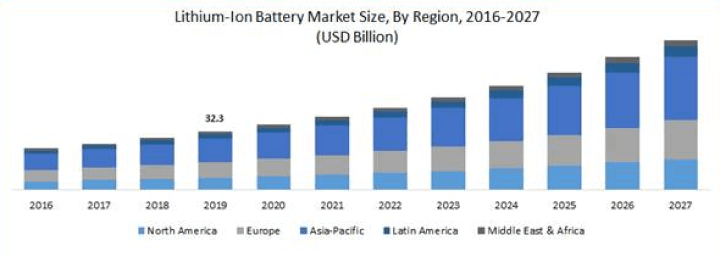

But whereas EVs are hailed as ecologically great when it comes to air quality, there are some very important environmental downsides that are not generally appreciated. And one of those is the rate at which EVs are consuming world resources of lithium, nickel and cobalt, a situation which is only going to escalate as the EV population grows.

The expansive Greenbushes lithium mine in Western Australia, known as the largest hard-rock lithium mine globally, situated south of Greenbushes town.

The expansive Greenbushes lithium mine in Western Australia, known as the largest hard-rock lithium mine globally, situated south of Greenbushes town.

Recycled Lithium is Too Expensive

The problem is severely exacerbated by the lack of and current expense of recycling. Estimates put the cost of recycled lithium at five times that of newly-mined lithium. And let’s not forget the brine-mining method of lithium production is negatively impacting the planet, not least because of the immense amount of water it consumes. It takes 2.2 million litres of water to produce a ton of lithium and can often leave local farming communities without sufficient water.

Moreover, the extraction of lithium through the brine-mining method has been linked to an increase in global warming. This is due to the vast amounts of fossil fuels used in the extraction process, which release significant amounts of carbon dioxide into the atmosphere[1].

So all you proud EV owners out there that see yourselves as eco-warriors, think again.

As for nickel, manganese and cobalt, these are rare and dangerous materials that are costly, and when it comes to cobalt, it’s best not to ask how that is sometimes mined in the Congo by child labour in hazardous conditions. The Congo supplies about 65% of the cobalt used worldwide.

Inefficient Recycling

Regarding the recycling of EV lithium batteries, there are a number of considerations. Firstly, a widely used process called pyrometallurgy is not that good at actually recovering lithium. It’s a crude process that involves melting batteries and trying to recover the important elements already mentioned.

With pyrometallurgy, a huge amount of energy is expended, heating the batteries to1500°c. Once melted, some of a battery’s raw materials can be separated. However, only cobalt and nickel can be recycled, and lithium and manganese are not recovered. So, it’s not efficient and is in itself environmentally questionable because of the toxic gases the process emits and the huge amount of energy it uses.

Another method is Direct Recycling. This actually takes the battery apart and retains both anode and cathode materials, and these are put through a refurbishment process for further use.

Industry pundits consider this approach to be more effective and safer. However, when it comes to the cost of it, there is the question of economy of scale. Lithium battery packs are constructed in sections, and it is a time-consuming task to break these down into their various components. The process needs to be automated, but this won’t fully happen until there are a lot more EV batteries going into recycling.

The financial problem here is reaching the tipping point where the number of new EV batteries being made balances with the number that are sent for recycling. Because the present production rates of new lithium batteries vastly outstrip the number going into recycling, the development of expensive automated production equipment to speed up the Direct Recycling method is slow.

Mountains of Dead Batteries

A further environmental worry is the demand for newly mined lithium has grown by nearly 30% in the past three years, and with the global growth of EV sales, a massive mountain of dead electric car batteries will soon create pressures to solve recycling problems. By 2028, researchers predict that the world will have more than a million metric tons of used EV batteries to deal with.

This mountain of spent lithium batteries presents its own environmental dangers that, include fire. Incidents at waste facilities in the US and Europe have increased by nearly 40%, according to industry experts in recycling.

There is also the danger of local soil and water systems being contaminated by toxic materials leaching out of the piles of spent lithium batteries. And if that’s enough of a problem, then if electrolyte leaks from the batteries, it can react with water to produce toxic gases like hydrogen fluoride and release metals like nickel, cobalt and manganese into the surrounding area.

If it could be made profitable, increasing EV battery recycling would, in less than 20 years, reduce the global need for newly mined lithium by 25% and for cobalt and nickel by 35%, according to the Australian Institute for Sustainable Futures.

World supplies of lithium are not infinite, and estimates put reserves at 80 million tonnes. So what about alternatives or additional materials that could reduce the amount of lithium required or even extend its useful life in EVs?

Alternative Battery Technologies

Scientists are working on these, and there are some interesting candidates that include salt, iron and hemp.

Let’s start with what seems the most extreme of these, hemp.

Texas-based Bemp Research claims it has developed a lithium sulphur battery that uses hemp called B4C-hemp (Boron Carbide made from hemp). It believes its battery design would outperform many lithium battery characteristics and, importantly, would be much easier to recycle.

Another promising alternative is the lithium sulphur battery. These batteries can store much more energy than their lithium-ion counterparts, meaning they can last substantially longer on a single charge. They also use sulphur, a cheap raw material available as a by-product of the oil industry, instead of costly cobalt. However, current lithium-sulphur batteries face the challenge of a short lifespan due to the build-up of chemical deposits that degrade the cell[3].

This is because a hemp-based battery would not contain cobalt or nickel.

Another claim for B4C-hemp is in terms of safety because if the battery is damaged in, for example, a road traffic accident, the sulphur will combine with the lithium to form a protective layer that will not ignite.

So a natural plant that already provides fibre that is used in textiles, clothing, shoes, food, paper, bioplastics, insulation and biofuels could be a key element in providing EV batteries that are not an environmental problem waiting to happen.

Where Does Salt Fit In?

Salt is also on the list of possible alternatives, and scientists at the Karlsruhe Institute of Technology in Germany have developed a prototype battery based on seawater.

The sodium-ion battery (SiB) uses sodium ions as its charge carriers. It’sIt’s working principle and cell construction are similar to lithium-ion batteries, but lithium is replaced with salt as the cathode material. Salt belongs to the same periodic table group as lithium and therefore has similar chemical properties. It is naturally available in vast quantities, but it has some disadvantages, one of which is weight. It’sIt’s heavy, and that would add weight to an EV which would, in turn, decrease the operational range of an EV. There are also concerns about inadequate discharge cycles, which could reduce the operational life of an EV battery.

Iron Batteries have a Recycling Advantage

A lithium iron phosphate battery (LFP) uses iron phosphate as the cathode material and are recognised as having high energy density, long life and can work well in high temperatures. They are considered to be the greenest form of battery.

Importantly LFPs are known to be easier to recycle than lithium batteries.

Because they do not contain heavy metals or other toxic materials, they are less hazardous to handle during the recycling process.

Furthermore, lithium iron phosphate batteries (LiFePO4) offer several advantages over traditional lithium batteries. They have a longer lifespan, require no active maintenance, and are extremely safe. They also offer high power density, making them relatively small and light. Despite being more expensive initially, their long lifespan and zero maintenance make them a cost-effective solution in the long run[4].

LFP batteries are safer than lithium-ion batteries as they are less prone to overheating and catching fire, and they are cheaper to make. However, because they have a lower energy density, more would be required in an EV which could negate the cost advantages.

Is Hydrogen the Long-Term Answer?

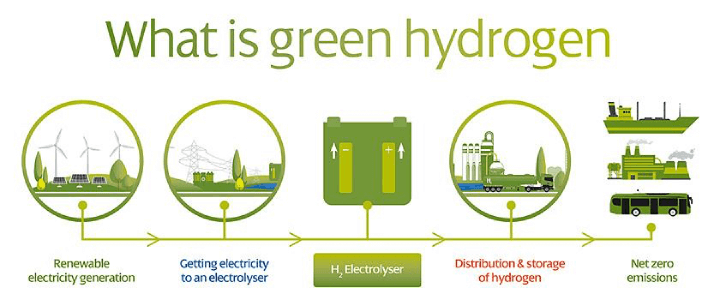

It’s widely recognised that hydrogen is a better long-term environmentally friendly way to propel vehicles - providing the hydrogen is green, i.e. it’sit’s manufactured using sustainable energy and not fossil fuels.

Basically, a hydrogen-fuelled vehicle has a fuel cell that produces electricity to drive the vehicle’s electric motor, and that electricity is created by a chemical reaction between hydrogen and oxygen. In the fuel cell, the hydrogen is split into electrons and protons, and the electrons are forced through a circuit which generates an electrical current. A major advantage of this process is the exhaust material emitted by the vehicle is environmentally harmless water.

So what’s the problem? Why aren’taren’t we seeing more hydrogen vehicles on the road? Two reasons. Firstly the cost of hydrogen fuel cells is very high, and secondly, there would have to be an adequate infrastructure of nationwide refuelling stations.

And let’s face it, we don’t even have that yet for EVs!

References

- Euronews. South America's lithium fields reveal the dark side of our electric future

- ScienceDirect. Pyrometallurgy

- Horizon Magazine. Cheaper, lighter and more energy-dense: The promise of lithium-sulphur batteries

- Super B. Benefits of Lithium Iron Phosphate Batteries