Eco-friendly Water-based Ink Revolutionises Printed Electronics Components

Environment | 21-04-2023 | By Robin Mitchell

Printed electronics hold great potential for revolutionising the way we interact with technology by enabling the creation of low-cost, flexible, and even stretchable electronic devices. Researchers have recently made a breakthrough by eliminating toxic solvents in the ink used for printed electronics and replacing them with a water-based solution. This development significantly enhances the environmental friendliness of this technology. In this article, we will explore the challenges presented by printed electronics, discuss the researchers' development of water-based ink, and examine how this advancement could shape the future of disposable electronics.

Duke University researchers have developed a new process for making fully recyclable printed electronics that replaces chemicals with water in the fabrication process. The team used three carbon-based inks to create fully functional, water-based transistors that can be fully recycled. The process could help reduce the environmental impact of electronics manufacturing and reduce human health risks.

What challenges do printed electronics present, what did the researchers develop, and how can it help with future disposable electronics?

What challenges do printed electronics present?

Printed electronics is a rapidly growing field that promises to revolutionise how we interact with technology. The ability to print electronic devices on a variety of substrates, including flexible and even stretchable materials, opens new opportunities for creating innovative and low-cost electronic products. However, as with any technology, there are also challenges that must be addressed.

One of the major challenges of printed electronics is the need for toxic chemicals. Many of the materials used in the fabrication of printed electronics, such as conductive inks and solvents, contain hazardous chemicals that can pose a risk to human health and the environment. For example, silver nanoparticles, which are commonly used in conductive inks, have been shown to be toxic to aquatic organisms and can also cause respiratory problems in humans if inhaled.

The environmental impact of printed electronics is another challenge that needs to be addressed. The production of printed electronics requires significant amounts of energy and water, which can have a negative impact on the environment. Additionally, the disposal of printed electronics can also pose a problem. Unlike traditional electronics, which can be recycled, many printed electronics are designed to be disposable, which can lead to significant amounts of electronic waste.

Finally, the concept of disposable electronics is a major challenge in the field of printed electronics. While the low cost and convenience of disposable electronics may make them appealing, the environmental impact of producing and disposing of these devices can be significant. Furthermore, the trend towards disposable electronics can lead to a culture of disposability, where products are designed to be used once and then discarded rather than repaired or recycled. The increasing demand for disposable electronics highlights the importance of developing environmentally friendly materials and processes for their manufacturing, minimising the overall impact on the environment.

Researchers develop water-based ink for printed electronics

Recognising the challenges faced with printed electronics and their use of toxic solvents, researchers from Duke University have developed a new process for making printed electronics that replaces toxic solvents with a water-based solution.

The printed devices are made from three different carbon-based inks, including semiconducting carbon nanotubes, conductive graphene, and insulating nanocellulose. Initially, the researchers faced a challenge when trying to adapt the original process to only use water, particularly with carbon nanotubes, as water-based inks tended to cause the carbon nanotubes to clump together, resulting in uneven and ineffective layers. This was because the hydrophobic nature of carbon nanotubes made it difficult for them to disperse uniformly in water-based solutions.

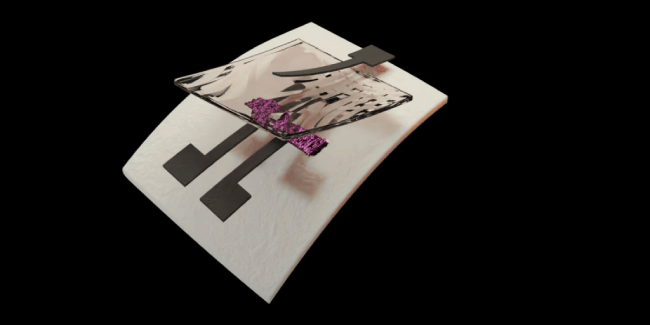

By printing insulating cellulose onto other carbon-based components, researchers have produced the world's first fully recyclable printed transistor, aiming to encourage the production of more recyclable electronics to address the increasing global issue of electronic waste.

To create a water-based ink that prevents the carbon nanotubes from clumping together, they introduced a surfactant, similar to detergent, which allowed the carbon nanotubes to spread evenly on the surface. While this method did eliminate the need for a toxic solvent, it isn’t without its flaws; the resulting layer was not sufficiently dense enough to allow high currents. At the same time, the researchers also noticed that the inclusion of the surfactant prevented other layers from sticking, making it impossible to create layered structures.

However, the surfactant used to keep the carbon nanotubes from clumping also prevents additional layers from adhering to the first. To overcome this issue, the researchers developed an additional cyclic process that involves rinsing the device with water and drying it at relatively low heat between layer applications. This additional cleaning cycle reduces the surfactant, allowing for subsequent layers to adhere well. This new process not only eliminates the need for toxic chemicals but also operates at far lower temperatures than existing solutions, which also has the added bonus of reducing energy consumption.

A rendered image of the world's first fully recyclable printed transistor.

Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke, who led the study, said, “Putting layers on top of each other is not as easy as putting them down on their own — but that’s what you have to do if you want to build electronic devices with printing.” Franklin and his group developed a cyclical process in which the device is rinsed with water, dried at relatively low heat, and printed on again to create fully functional, fully recyclable, and fully water-based transistors.

How can future printed electronics be helped with this new technology?

While the technology is still in its infancy, researchers are already looking at the environmental impact of disposable printed electronics and developing technologies to minimise this impact. But the development of water-based solvents isn’t just advantageous from an environmental point of view; they also simplify the production process. Simplified manufacturing processes have the benefit of reducing production costs while also opening the technology to a far greater audience.

Overall, what the researchers have demonstrated here is an exciting direction for printed electronics to take. Future devices will be more environmentally conscious, and the eventual rise of disposable electronics will be fully sustainable. However, there may still be challenges to overcome, such as improving the performance of these water-based transistors to match those produced by traditional methods and ensuring large-scale manufacturing processes can effectively implement this new technology. Addressing these limitations would be essential for the widespread adoption of this environmentally friendly approach.

Furthermore, this technology could have a significant impact on the production of screens and displays. The current fabrication technology for these components is high-energy and relies on hazardous chemicals and toxic gases, which have caught the attention of the US Environmental Protection Agency for their negative environmental impact. By adopting the environmentally friendly processes developed by the Duke University researchers, the entire electronics industry can move towards a more sustainable and greener manufacturing path. For example, this technology could greatly benefit the smartphone, tablet, and television industries, where the production of screens with a reduced environmental footprint would be highly advantageous.

Franklin stated, “The performance of our thin-film transistors doesn’t match the best currently being manufactured, but they’re competitive enough to show the research community that we should all be doing more work to make these processes more environmentally friendly.” This technology could potentially be used in the manufacturing of other electronic components like screens and displays, making the entire industry more environmentally friendly.

Source: Duke University. (2023, February 28). Water-Based, Recyclable Printed Electronics Offer Greener Manufacturing Path. Pratt School of Engineering. Retrieved from https://pratt.duke.edu/about/news/water-recyclable-printed-electronics