Wootzano Receives Robotic E-Skin Funding

| 10-09-2020 | By Sam Brown

Robotic systems are greatly improved with the use of sensors that mimic human skin. What is e-skin, how does it work, and what do Wootzano produce?

Why is robotic dexterity important?

The introduction of robotics into the industrial landscape has resulted in significant improvements in the final quality of manufactured parts, increased consistency, increased production rates, and helped to develop new products that can only be produced by machine. While robots are very good at repetitive tasks, they are not so good at handling tasks that have variance. For example, picking up eggs can be done with a specialised sucker, but using a generic robotic hand is difficult as eggs can vary in size, weight, and structural integrity. However, the human hand can pick up and handle eggs with extraordinary precision, and no matter the conditions an egg can be handled without breakage. Thus, if robotic systems could be given the dexterity and sensitivity of human skin, then their potential applications could significantly increase.

What is E-Skin?

Unlike science fiction, human skin cannot be grown over endoskeleton alloys with connected neural systems to a humanity ending AI chip. However, there is a lot of scientific development in the area of electronic skin or e-skin for short. Such skin essentially is a material that has the flexible properties of human skin, while also integrating sensors for detecting pressure. The most basic form of e-skin would utilise basic touch sensors that detect the presence of an object. However, true e-skin should be able to detect pressure, as well as be flexible without wearing down the sensor. Such e-skins often rely on piezoresistive materials for their sensor, and stretchable polymers for the skin material itself.

Who are Wootzano?

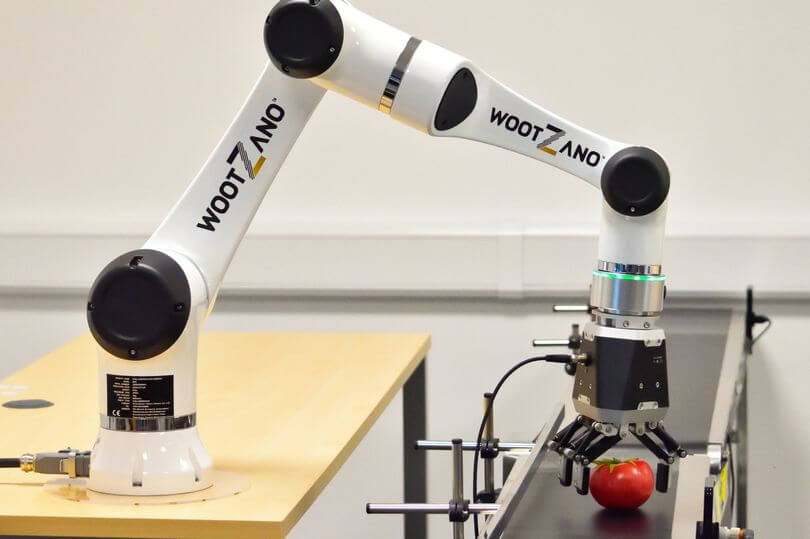

Wootzano are a robotics company that specialises in e-skin for robotic systems. Founded by Dr Atif Syed, Wootzano has a strong history of electronics, bionanotechnology, semiconductors, and business throughout the various researchers and teams. Through continual research and development, Wootzano have developed an e-skin that can allow robots to feel objects similarly to humans, and the sensors can be easily produced with a production yield of 99%. The skin is made using a specialised elastomer that has metal electrodes deposited using photolithography, a common technique found in the semiconductor industry. The advantage of the Wootzano e-skin, called Wootzkin, is that it is flexible, stretchable, and provides a piezoresistive pressure reading while not being degraded through use. This allows for the skin to be used on most robotic systems, and its full compliance with food standards enable it to be used in controlled areas of industry.

Wootzano Receives a Six-Figure Funding Package

The development of e-skin is essential to the robotics industry, but the recent COVID-19 pandemic has put a spanner in the works for many companies. However, while the development of the e-skin may have been halted to a degree (with the lockdown and remote working), there is an increasing demand for automated vegetable and fruit pickers.

Credit: Wootzano

Of course, this increase in demand has put pressure on Wotzano, and as a result, are now looking for investment to ensure that they can provide robotic systems with touch capabilities by the first quarter in 2021. To help with this, Wootzano have recently received a £1.2 million grant from the UK government through the Innovate UK grant scheme. This, along with investor funding, will help Wootzano meet the demand for e-skin in the agricultural sector, and thus further help with automating food-related industries. However, any industry that handles sensitive objects will significantly benefit from such e-skin, but only time will tell where exactly it becomes incorporated.

Read More