29-11-2021 | JLCPCB | Design & Manufacture

JLCPCB's SMT service can impact the quality of your product. It allows you to manufacture printed circuit boards with less time and cost.

What is Surface Mount Technology?

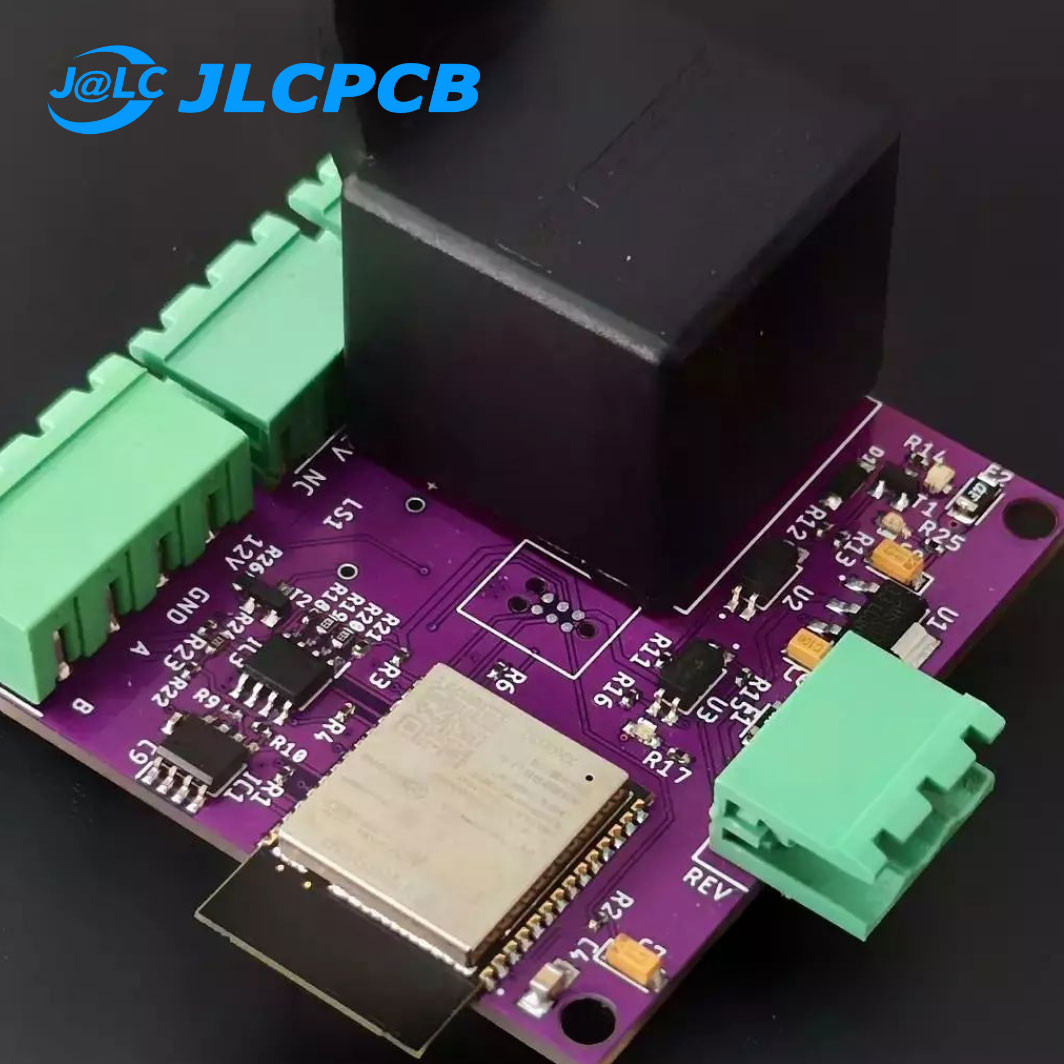

SMT is a technique for attaching electronic components to the surface of PCB without drilling. Surface Mount Devices are the electronic components used in this technology. In figure 1, we have an SMD resistor.

Figure 1 - SMD Resistor.

The main characteristic of these components is the absence of pins in their structure. Their solder locations are on the corners of the chip or Chips with a flat surface or BGA. Using SMT technology, users can reduce costs for your electronic products.

Most designers develop their first electronic boards with components welded into holes. THT technology facilitates the assembly process because you need few materials to carry out the welding process. It allows adjustments and manual replacement of electronic elements by a designer. If you have already tested and validated a product, you need to consider using JLCPCB's SMT services. It will allow you to produce your electronic boards: On a large scale, with more incredible manufacturing speed, lower financial cost, and high-quality production. Over time, technology has developed a great deal, and more and more products need new features. Among these features, the company has reduced size and weight. To achieve size and weight reduction, you need to use SMT Technology. Weight and size saving is essential in aerospace and aircraft applications, for example. Thus, SMD's devices do not need holes. They have smaller terminals (or do not) and is smaller than the components used in through-hole technology. This allows you to build a smaller board with:

It is possible because there is no electronic board drilling step. Its SMT Service of assembly and welding is automatic and quick. This allows the user:

The company has an assembly service to assist you with safety, confidence, and an automated process. It avoids any human error and speeds up the delivery of your product. But, what are the differences and benefits between PTH and SMD components?

Difference between Surface Mount Devices and Pin Through-Hole Components

Many projects use these two types of components. Currently, the company produces more than 600.00m² by month of PCBs with these two technologies. The complaint rate for this production capacity is less than 0.2%. It makes JLCPCB one of the largest companies in Asia PCB. But what is the difference between these two component technologies?

Through-Hole Components

Since 1940 the companies have used components with leads. It has proven to be reliable with the following points:

This made it easy to use these components in creating circuit board designs. But, holes make routing on multilayer circuit boards difficult. It occurs because the holes make routing new tracks difficult. Holes pass through all layers of PCBs.

The through-hole component assembly process

Position the components by passing the leads through the holes in the PCB, followed by inspection and correction of the positioning of electronic components. After, that they have the wave soldering process. Users need to expose one side of the PCB in a solder wave to fix the terminals in the PCB holes. But, over the years, surface mount technology with SMD components has emerged and raised the level of technology for PCBs.

Surface Mount Devices

Since 1950 the military has employed surface-mounted devices. In 1970, the Japanese built several electronic products using this technology. They saw a reduction in production cost, and knew this would be interesting for consumers. SMT technology fixes the SMD components to the surface of the electronic board. This reduces the circuit size, weight, and cheaper production for our customers.

To ease product creation and further reduce costs, the company offers new strategies. It has a pre-order library with more than 80,000 electronic components. The fluctuating market prices affect the costs of products. Pre-order reduces costs and risks of high prices for our customers.

How to avoid the risks of fluctuating electronic component prices

The world market is volatile. The prices of certain products can go up or down. Several factors can change buying behaviour. The law of supply and demand can be crucial in producing and selling products and services on the market. The pandemic, for example, affected the prices of many electronic products. It occurs because a large part of the world's population is working from their homes. This has increased the demand for computers, webcams, and other electronic devices. So, the market needed to increase demand to produce more devices. The consequence of this was an increase in prices because these devices were more valued. This affected the producer and final consumer. But, JLCPCB presents ways to change this scenario. Their service offers better price stability with less risk for its customers. The service consists of a library with more than 80,000 electronic components. You can buy at a low cost, safely, and easily stored in a personal account. The significant advantages are: the company stores your electronic components, and you'll not suffer any risk of price fluctuations that occur in the market. This process is possible because there is a specialised team available. They study, receive, and analyse customer demands and market price fluctuations. It allows ensuring the availability of the most used electronic components for your customers at better prices. Through this, you have access to the best components and significant profits to sell your products. The company provides the complete supply chain for clients to design a project. SMT technology produces lower costs with an automation process. In some cases, you can receive the project and assemble your products in your laboratory. In this case, you will receive the stencil boards to ease the soldering process of the PCB.

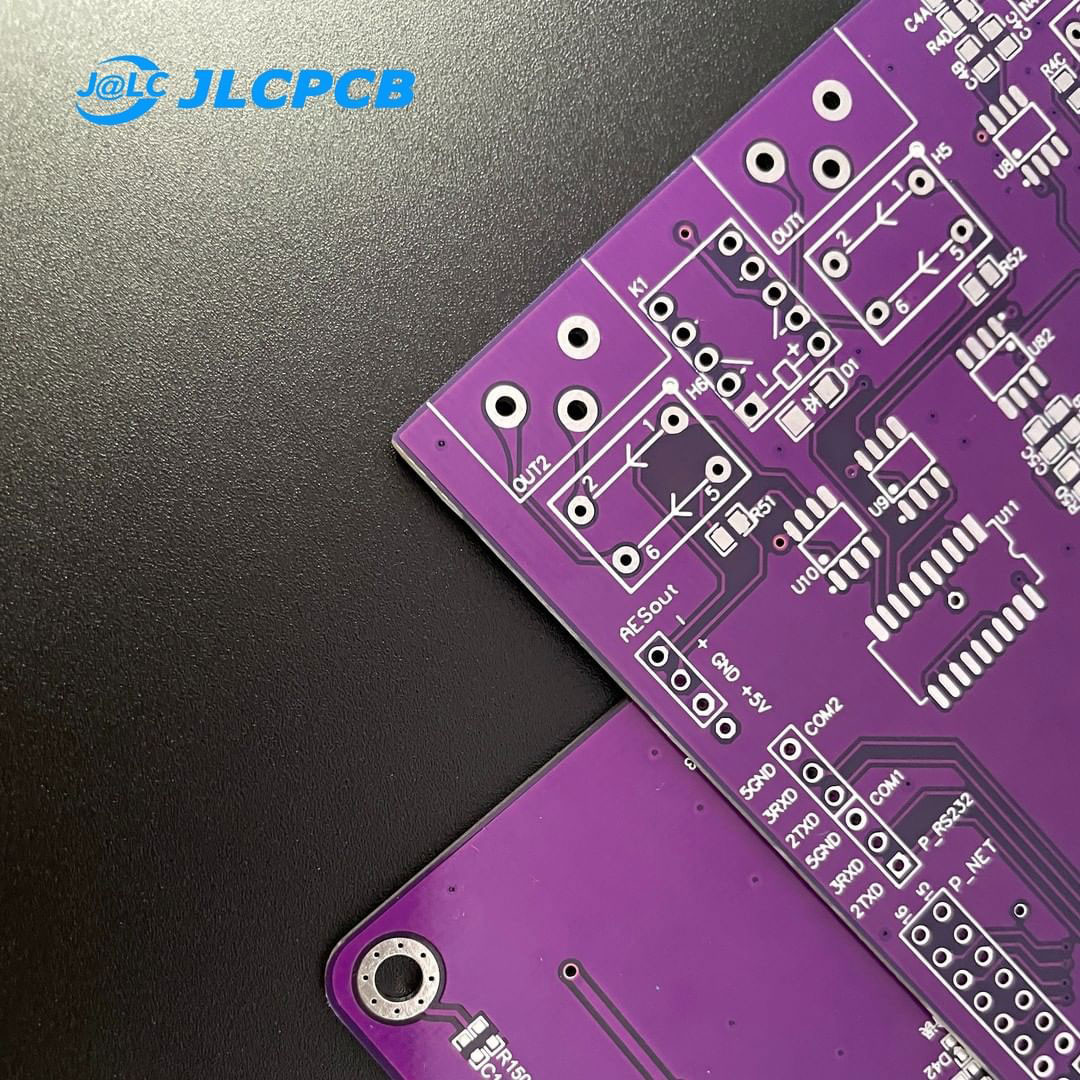

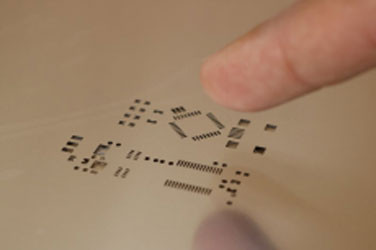

PCB stencil is a stainless-steel sheet cut with laser cutting technology. The cuts represent the pad positions of the SMD components. It serves two important purposes: it allows you to apply the solder paste, making the PCB assembly process faster.

See the Stencil PCB in Figure 2.

Figure 2 - PCB Stencil for a PCB.

Position the PCB Stencil during the soldering process above the printed circuit board. After that, apply solder paste in the stencil region with the aid of a lamina. Spread the solder will to all pad regions of the SMD components. Finally, remove the stencil and place the SMD components in their locations. Apply heat to weld the solder to the SMD's component terminals. The company produces Stencil PCB boards through a rigorous process. It uses laser cutting machines with high-precision movement. This allows two things: cuts with the lowest error rate and impacts the quality for applying solder paste.

What benefits and when to use SMT Service?

Use SMT technology when you need a compact circuit with higher speeds and is lightweight. Also, there are other advantages to using this technology.

Manufacturing speed and efficiency: The manufacturing process is fast and efficient, as there is no need to create holes in the electronic board. This eliminates setup time on machines.

High density of electronic components: You can add more components on both sides of the electronics board. This allows you to build boards smaller and with more components.

Weight of SMD components SMD's components weigh one-tenth the weight of their counterparts in through-hole technology.

Flexibility in project construction: You can combine both THT and SMT technologies on the same board.

Costs: SMD components are cheaper than (THT) components with leads. JLCPCB offers more than 800,000 electronic components at a reduced price that allows you to assemble any product for the market. But, there are some points to watch out for when working with SMT technology.

These are some essential alert points for anyone who wants to work with SMT technology. JLCPCB SMT service has the technology and support you need to develop your product at any time.

JLCPCB develops much more than printed circuit boards. Its products are present in aircraft, computer motherboards, microprocessor systems, electric cars, research laboratories, and various electronic products in homes.