Electronic Ink Enables Flexible, Shape-Shifting Electronics

Insights | 01-08-2025 | By Robin Mitchell

Scientists invent shape-shifting ‘electronic ink’, paving the way for next-gen flexible devices – Simok Lee et al.

Key Things to Know:

- STAR ink is a gallium-based printable electronic ink that transitions between rigid and soft states with heat exposure.

- The ink integrates conductivity and stiffness modulation, eliminating the need for separate mechanical structures.

- It supports scalable manufacturing using screen printing, dip coating, and other conventional methods.

- Applications include wearable electronics and brain implants, where softening reduces mechanical stress and improves biocompatibility.

For years, the vision of electronics that can seamlessly adapt to their surroundings has driven innovation in wearables, biomedical devices, and soft robotics. But real-world progress has often lagged behind the promise, limited by fundamental material and manufacturing constraints.

A team of researchers at KAIST may have taken a significant step toward overcoming these barriers. Their newly developed gallium-based electronic ink can transition between rigid and soft states, opening the door to circuits that change their mechanical properties on demand.

What makes this ink different from existing flexible materials, how does it work, and could it finally enable a new generation of truly adaptive electronics?

The Challenge with Flexible Electronics

Flexible electronics have long promised a future where technology conforms to us, not the other way around. From wearable health monitors to foldable displays and soft robotics, the idea of electronics that bend, stretch, and adapt to their environment is compelling. But behind the marketing gloss lies a persistent set of engineering challenges that remain far from solved.

The core issue is material science. Traditional electronic systems are built on rigid materials like silicon, copper, and glass, materials chosen for their excellent electrical performance, mechanical stability, and proven integration into high-volume manufacturing. However, these materials are inherently brittle. They crack under strain, delaminate under flex, and simply don't belong in applications that demand mechanical compliance.

Material Trade-Offs in Flexible Electronics

On the other hand, materials that are soft, stretchable, or conformable, such as conductive polymers and inks, often suffer from significant trade-offs. Conductivity is lower. Long-term reliability is questionable. And integration with dense circuitry or logic-level components is frequently limited by thermal and mechanical constraints.

For example, while flexible printed circuits (FPCs) are common, they still rely on copper traces and are only flexible in limited ways, often requiring specific bend radii, carefully controlled strain relief, and rigid support structures for more sensitive components. In practice, many so-called "flexible" devices are hybrids, rigid cores wrapped in soft packaging, rather than fully soft systems.

Manufacturing Challenges for Soft Systems

From a manufacturing standpoint, flexible electronics complicate the process flow. Traditional surface-mount technology (SMT) lines are optimised for flat, rigid boards. Once you introduce a flexible or stretchable substrate, everything, from pick-and-place alignment to solder reflow profiles, becomes more difficult. Consistency suffers. Yield drops. Costs rise.

The stakes are especially high in sectors like medical technology and soft robotics, where devices need to function reliably under constant movement, temperature variation, and environmental exposure. A wearable device that's soft and skin-compatible is no good if its interconnects fail within a few hours. A brain implant that deforms to match tissue must still maintain electrical integrity at micrometre scales.

To be clear, progress is being made. Research into gallium-based inks, nano-composite conductors, and stretchable substrates is promising. But we're not yet at the point where flexible electronics can match the performance, reliability, and manufacturability of rigid systems. For most applications, designers must still make hard choices between flexibility and function.

Gallium-Based Ink Enables Shape-Shifting Circuits

Researchers have developed a new printable "electronic ink" capable of transitioning between rigid and soft states when exposed to heat, a potential game-changer in fields ranging from biomedical implants to soft robotics. Published in Science Advances on May 30, this innovation demonstrates how smart materials and smart chemistry can come together to address one of electronics' most stubborn constraints: mechanical rigidity.

How STAR Ink Overcomes Gallium’s Limitations

The ink’s formulation — referred to as STAR (STiffness-Adjustable temperature-Responsive) ink — addresses gallium's traditional drawbacks by chemically separating the dispersion and sintering stages. This enables more stable processing and patterning without premature solidification, allowing for seamless transition between soft and rigid states during operation.

The new ink, however, aims to address this limitation. Developed by a team led by Professor Jae-Woong Jeong at KAIST (Korea Advanced Institute of Science and Technology), the ink blends microscopic gallium particles with a polymer solvent called dimethyl sulfoxide (DMSO). Gallium, a low-melting-point metal, is solid at room temperature but liquefies just below body temperature, a property that enables stiffness modulation based on heat exposure.

What sets STAR ink apart from earlier gallium-based solutions is its pH-controlled sintering mechanism. During heating, the solvent (DMSO) decomposes into a mildly acidic mixture, which removes oxide layers from the gallium particles and induces inter-particle sintering. This results in a conductive network embedded in a hydrophilic polymer matrix, enabling both electrical performance and mechanical reconfigurability in a single step.

The science behind the ink is elegant. Once printed, gentle heating causes the solvent to decompose, creating a mildly acidic environment that strips away gallium's natural oxide shell. This allows the metal particles to melt and fuse, forming continuous, conductive pathways within the ink. The result is a circuit that not only conducts electricity, but also changes mechanical properties on demand.

This capability eliminates the need for separate mechanical support or actuation systems. Because the ink integrates both conductivity and stiffness modulation, it simplifies the architecture of transformative electronic systems, particularly those requiring tight packaging constraints or deployment in sensitive biological environments.

Manufacturing Potential and Scalability

The ink can be printed down to features as small as 50 micrometres, finer than a human hair, using common techniques like screen printing or dip coating. That's a major plus from a manufacturing standpoint, opening the door to scalable production without exotic tooling.

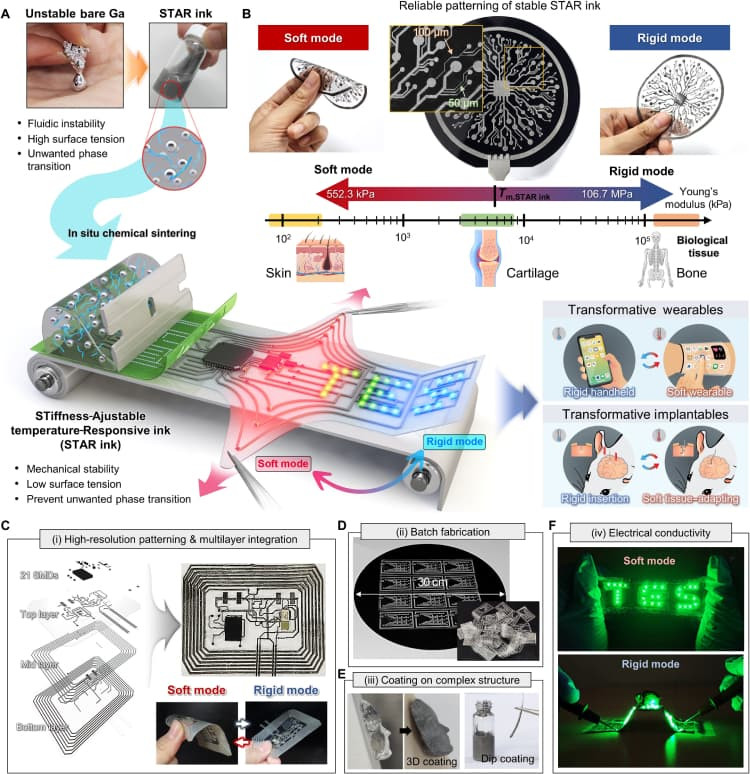

This diagram from the Science Advances publication offers a visual breakdown of STAR ink’s formulation, printing capabilities, and real-world applications — including wearable and implantable prototypes. It highlights the transition between soft and rigid states, and how that adaptability is leveraged across fabrication steps and use-case scenarios.

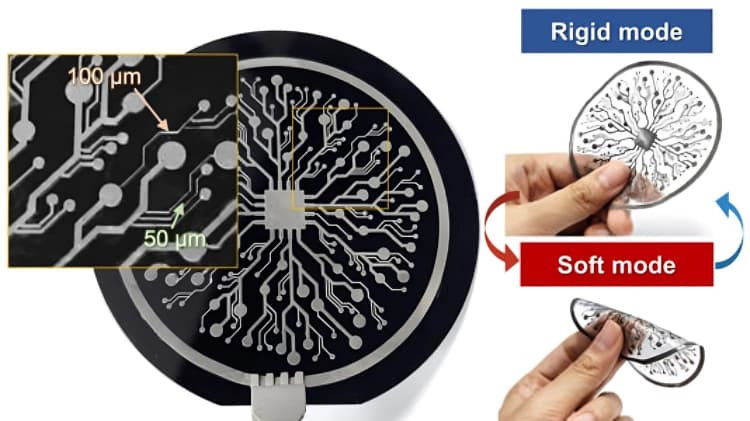

Fig. 1. STAR electronic ink enables room-temperature, solution-based fabrication of transformative electronic systems (TES). (A) Concept illustration of how STAR ink supports the creation of mechanically adaptive electronics using a room-temperature process. (B) Images showing large-area patterning and the ink’s ability to shift between a soft, tissue-like state and a rigid, bone-like state, with a 193-fold change in Young’s modulus. (C–F) Key features include: (C) high-resolution multilayer patterning with PCB-level design complexity, (D) scalable batch fabrication, (E) excellent coatability on complex 3D surfaces, and (F) stable electrical conductivity in both soft and rigid modes.

Real-World Performance and Scalable Fabrication

STAR ink’s compatibility with various deposition techniques — including screen printing, dip coating, and direct ink writing — means it can be used to fabricate multilayer circuits, including 3D conformal coatings, without specialised cleanroom infrastructure. This positions it well for large-scale, cost-effective manufacturing in industries such as medical wearables and soft robotics.

In lab tests, the material became over 1,400 times softer when heated. That opens the door for devices that are rigid when you need them to be, during surgery or mechanical assembly, and soft when deployed inside the body or on human skin.

Tests on thermally induced soft-rigid mode conversion showed that STAR TES (transformative electronic systems) could repeatedly switch between states with minimal resistance variation, even under 1000% strain. This behaviour is critical for devices subjected to constant deformation, ensuring stable signal transmission and mechanical reliability over extended use.

Demonstrating Real-World Use Cases

To show the technology in action, the researchers created two working prototypes. The first was a wearable device that behaves like a hard electronic at room temperature but softens on contact with skin for better user comfort. The second was a brain implant that remains stiff for precise surgical insertion, then softens inside the brain to reduce tissue irritation and inflammation, a longstanding issue in neurotechnology.

The neural probe application demonstrates how STAR ink can serve dual roles — providing the stiffness needed for insertion and then transitioning to a soft, tissue-conforming state. This reduces inflammation and foreign body response, as confirmed by immunohistochemical analysis comparing STAR-based and traditional rigid probes in vivo. The ink’s conductivity enabled simultaneous optogenetic stimulation and neural recording without additional electrode materials.

Could this ink be the key to future wearables?

Gallium has long been considered promising for flexible electronics, but until now, its high surface tension and tendency to oxidise have made it impractical for circuit printing. Jeong's team overcame this with chemical control, not brute force. By focusing on the ink's acidity and particle dispersion, they enabled a room-temperature manufacturing process for tunable-stiffness electronics.

As Jeong noted, the key breakthrough was enabling "the electrical and mechanical connection of printed gallium particles," something previously considered nearly impossible at room temperature on flexible substrates.

While it's still in the early days, this development marks real progress in the pursuit of truly adaptive electronics. If the ink proves reliable in wider testing and scales as expected, it could radically simplify the production of medical devices, wearable tech, and morphing machines.