The Industrial Internet of Things (IIoT), Because Machines Get Lonely, Too

Educational | 17-11-2023 | By Gary Elinoff

Key Things to Know:

- IIoT has evolved from ARPANET to a cornerstone of Industry 4.0, reshaping industrial operations.

- It plays a crucial role in various sectors, from manufacturing to energy management, enhancing efficiency and decision-making.

- Emerging technologies like AI, 5G, and edge computing are set to further revolutionize IIoT capabilities.

- The future of IIoT promises even greater integration and innovation, impacting industries and society at large.

Introduction to IIoT

Well, not really. But like people, machines excel when they communicate with other machines across the hierarchy. NewParagraph Picture a manufacturing floor where robotic arms operate in perfect sync. Each arm is 'aware' of the others, optimizing tasks to boost efficiency and minimize downtime.

This scenario transcends mere data exchange. It's about a seamless flow of information that bolsters overall efficiency and decision-making. Machines shine when they make their own decisions. This autonomy not only empowers them but also slashes the margin for human error. It reduces the need for extensive, error-prone communication, streamlining processes in previously unimaginable ways.

Sound familiar?

In purely human situations, the people on the ground usually have a better point of view than decision-makers far afield. This is because they are directly engaged with the situation at hand, offering insights that might be overlooked from a distant perspective. Maybe machines can’t get lonely (yet), but in many ways, machine-based systems aren’t dissimilar to human organizations. They thrive on interaction, information exchange, and a certain level of autonomy. As we’ll see, the IIoT allows complex electromechanical systems to function like Western corporations and militaries, where the ground pounders don’t only execute orders, but they can also act on their own without explicit orders for superior results. This level of autonomy and intelligence in machines mirrors the initiative and decision-making seen in successful human teams.

Understanding this parallel between human organizations and machine systems sets the stage for exploring the origins and evolution of the Industrial Internet of Things (IIoT).

But we’re getting ahead of ourselves. Let’s start at the beginning and see how the IIoT came about. This journey will take us through the evolution of industrial machinery from simple, single-purpose devices to interconnected, intelligent systems that are reshaping the very fabric of industry.

The Origins of IIoT: From ARPANET to the Internet

Understanding the parallel between human organizations and machine systems sets the stage for exploring the origins and evolution of the Industrial Internet of Things (IIoT).

But we’re getting ahead of ourselves. Let’s start at the beginning and see how the IIoT came about. This journey will take us through the evolution of industrial machinery from simple, single-purpose devices to interconnected, intelligent systems that are reshaping the very fabric of industry.

The IIoT's origins link to the ARPANET of the 1960s, the forerunner of today's Internet, which laid the foundation for the IoT. This vision of connectivity took a significant leap forward with the birth of the modern Internet, a direct descendant of ARPANET.

Originally, ARPANET was a modest network, linking just four key locations: UCLA, the Stanford Research Institute, UC Santa Barbara, and the University of Utah. From these humble beginnings, a technological revolution was born.

Have you ever wondered how the Internet evolved from its early days? Let's dive into a pivotal moment in digital history.

The ARPANET Begets the Internet

The official birth of the modern Internet, the progeny of ARPANET, is marked on January 1, 1983. This pivotal day saw the adoption of the Transfer Control Protocol/Internetwork Protocol (TCP/IP) by ARPANET and the Defense Data Network, establishing a universal communication standard. This protocol enabled flawless message exchange across diverse computer systems, setting the stage for the Internet as we know it.

The widespread adoption of the Internet laid the groundwork for the next revolutionary concept: the Internet of Things (IoT) and its industrial counterpart, the IIoT.

The impact of this development has been monumental. While estimates vary, it's widely acknowledged that over half of the world's population now has access to the Internet. This connectivity has transformed the planet into a vast, interconnected village, breaking down barriers and fostering global communication.

But the story of the Internet's evolution doesn't end there. Its expansion and adaptation have paved the way for the next technological leap: the Internet of Things and, by extension, the Industrial Internet of Things.

The IoT and the IIoT

While the Internet connects people and ideas, the Internet of Things (IoT) allows near-instant communication between things located anywhere. As described by Oracle[1], through the IoT, “physical things can share and collect data with minimal human intervention. In this hyperconnected world, digital systems can record, monitor, and adjust each interaction between connected things. The physical world meets the digital world—and they cooperate.”

The widespread adoption of the Internet laid the groundwork for the next revolutionary concept: the Internet of Things (IoT) and its industrial counterpart, the IIoT.

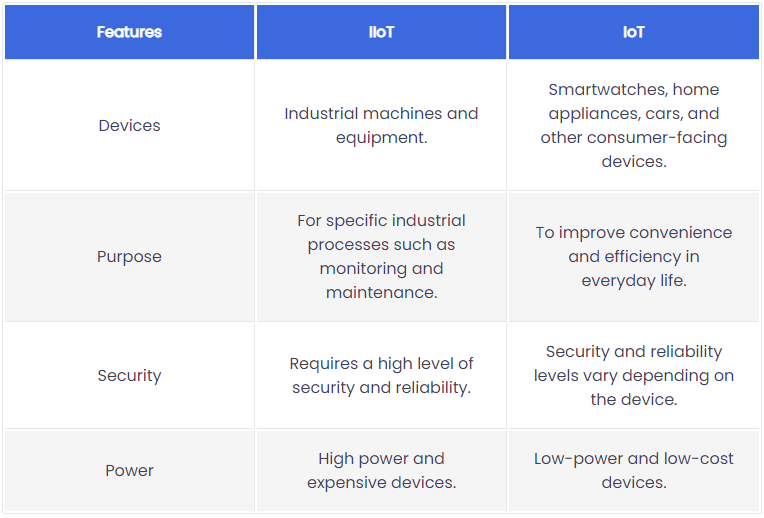

IIoT vs. IoT: Understanding the Differences

But what is the difference between the IoT and the IIoT?

It’s actually hard to differentiate, but IIoT can be thought of as a subset of the IoT. The IoT is a more inclusive term, generally meant to focus on consumer devices such as smart homes, wearables or appliances. While the IoT broadly encompasses consumer devices, the IIoT, a critical subset, focuses on industrial applications.

The IIoT focuses on industrial, energy and the smart grid. A key difference is that malfunction in consumer-based IoT can cause inconvenience for consumers, but malfunctioning IIoT applications can have more serious consequences. For this reason, IIoT systems must be more robust.

Additionally, IoT systems are often proprietary, but IIoT systems need to adhere to established standards so that they can accommodate the addition of new machines and even whole new systems that will certainly need to be added onto evolving oil pipelines, manufacturing floors or the power grid.

Amazon’s Alexa, employing the Amazon Web Service (AWS), is an example of the IoT. In this case, Amazon does provide a proprietary consumer standard and a universe of devices that can be readily added by consumers with little difficulty.

Amazon Alexa for IoT. Image source: AWS IoT for the Connected Home video

The IoT and the IIoT Contrasted

AirDroid[2] offers a concise chart summarizing the differences between the IioT and the IoT

Differences between the IIoTT and the IoT. Image source: AirDroid

Both the IIoT and the IoT can rely on the Internet for communications and connectivity. They also use sensors to collect information and can employ electromechanical actuators to effect change in the real world.

The Role of IIoT in Industry 4.0

Perhaps the most important “use case” for the IIoT has been on the factory floor, where it’s made a new industrial revolution possible. It is widely accepted that there have been four industrial revolutions, and as defined by Microsoft[3] they are:

- Mechanization: Steam-based machines (18th century)

- Mass production: Electricity, oil, and gas power and assembly lines (19th-20th century

- Computation: Computer-based influence and data analysis (Late 20th century)

4th Information Technology and AI (Early 21st century)

Microsoft further states that “Industry 4.0 is the transformation occurring in manufacturing to integrate digital technologies such as cloud computing and analytics, AI and machine learning, and the Internet of Things (IoT) into production facilities and operations. Also called the fourth industrial revolution or manufacturing 4.0, industry 4.0 is characterized by improved efficiencies such as increased automation, predictive (proactive) maintenance, and self-optimized process improvements.”

The reader should note that in practice, the terms IIoT and IoT are often used interchangeably, and IIoT is sometimes used instead of Industry 4.0. This can cause some confusion.

While the terminology might overlap, the practical applications of the IIoT are distinct and diverse, as we will see in the following examples.

Essential Technologies Complementing IIoT

These include Edge Computing, Embedded Systems, 5G and Artificial Intelligence. In actual practice, these technologies are more prevalent in more complex, critical IIoT applications than in the simpler IoT world.

The convergence of these technologies is not just a theoretical exercise; it's the driving force behind the fourth industrial revolution, known as Industry 4.0.

- Edge Computing employs local computational power to allow for decisions to be made right at the point where the computational system interfaces with the real world – where the rubber meets the road! This affords several advantages, such as far lower latency and better security. Edge Computing doesn't just sit at the periphery; it makes critical decisions where it matters most.

- Embedded Systems generally include a sensor, computational intelligence and a means to communicate with the Internet. This can be a package including several components or a combined system on a chip (SOC) contained within one monolithic unit. The computational elements used on SOCs are often ARM processors, which don’t exist as physical devices. Rather, they are the functionality bought by SOC manufacturers which fabricate the processor directly onto the SOC that is being built.

- 5G can offer improved speed as compared to legacy 4G. Its main benefits, at present, are best enjoyed through the use of private networks. It can allow components of a factory IIoT system to communicate at blindingly fast speed, reducing or limiting the issue of latency.

- Artificial Intelligence (AI) refers to the capacity of computational systems to recognize patterns and/or to learn from experience. Having AI at the “edge” of an IIoT system allows it to make decisions on the spot and not need to refer to an AI system that may exist thousands of miles away. In addition to reducing latency and increasing the speed of decisions, it eliminates the need to transmit huge amounts of raw data over the Internet, where it can be hacked by malevolent actors.

How the IIoT is Now Being Used

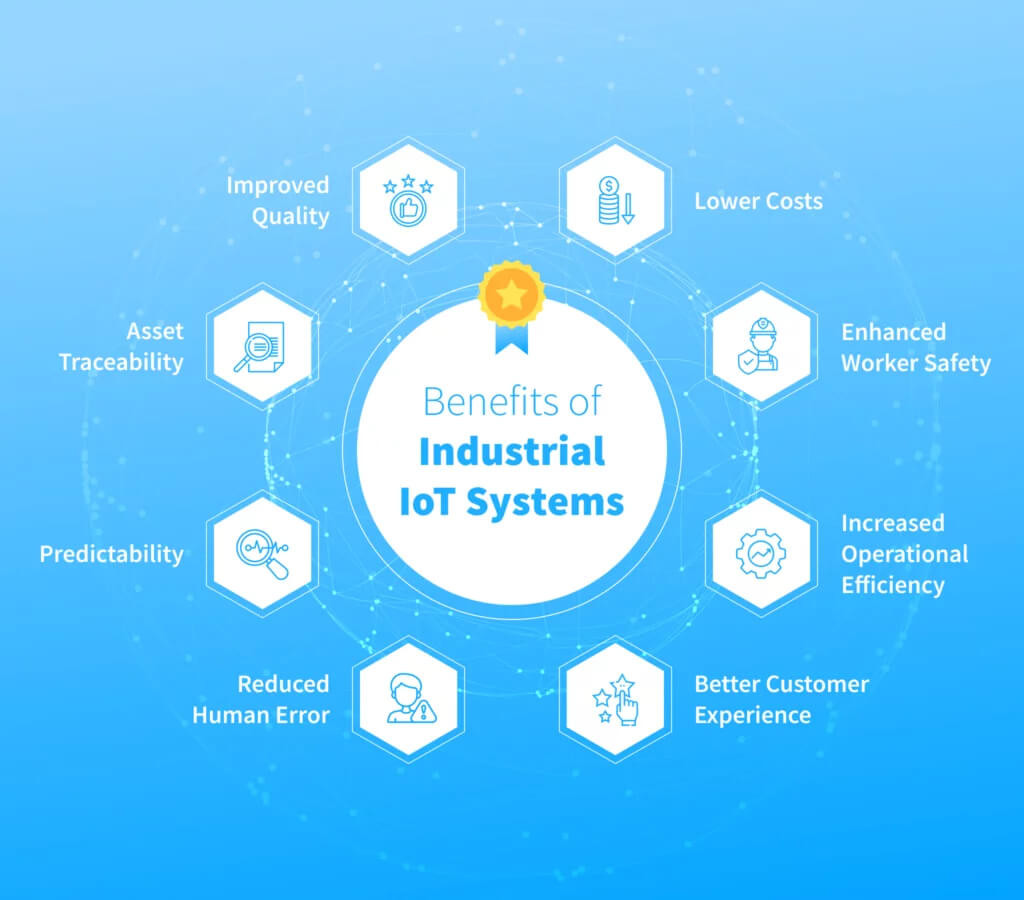

Industry 4.0, the revolution on the factory floor, was made possible by the IIoT, but that’s just the beginning. NIX United[4] offers a list of 10 IIoT applications. They are:

- Automation

- Advanced analytics

- Quality Control

- Predictive Maintenance

- Asset Tracking

- Worker and Plant Safety

- Remote Monitoring

- Inventory Monitoring

- Supply Chain Management

- Energy Management

Use cases for IIoT. Image source: Nix United

And the list goes on. While we can’t cover them all, here’s one whose importance will stand out because what’s more important to human life than water?

Real-Life Applications of IIoT

While the IIoT has a broad range of applications, let's delve deeper into two specific examples to understand its real-world impact better.

1. Predictive Maintenance in Manufacturing

Another significant application of IIoT is in predictive maintenance within the manufacturing sector. Traditional maintenance schedules rely on predetermined intervals, often leading to unnecessary downtime or unexpected equipment failures. IIoT changes this paradigm by using sensors to monitor equipment performance in real-time.

By analyzing data from these sensors, IIoT systems can predict when a machine is likely to fail or require maintenance, allowing for timely intervention. This approach not only reduces downtime but also extends the life of the equipment, leading to significant cost savings and increased efficiency in manufacturing processes. For instance, a factory might use IIoT to monitor the wear and tear of critical components in machinery, scheduling maintenance only when necessary, rather than based on a fixed schedule.

These applications are just the tip of the iceberg. The IIoT presents numerous challenges but also unprecedented opportunities, as illustrated by the following examples.

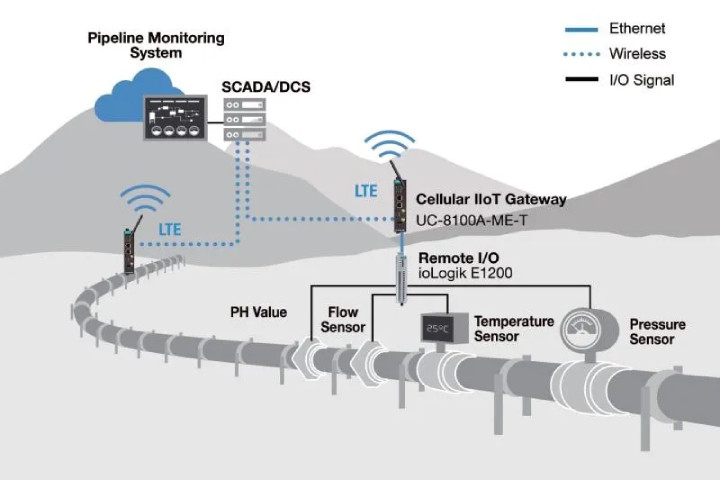

2. Water Pipeline Monitoring

One standout application of IIoT is in monitoring water pipelines. Madison Technologies1 illustrates a system that employs a combination of sensors and cellular IIoT gateways along the pipeline. This setup enables continuous, real-time monitoring of the pipeline's condition, which would be prohibitively expensive and logistically challenging with human inspectors.

Each gateway along the pipeline relays data to a central host, which can be located anywhere globally. This system allows for early detection of leaks, pressure anomalies, or potential failures, ensuring timely maintenance and reducing the risk of catastrophic failures. This application not only exemplifies the efficiency of IIoT but also highlights its role in preserving essential resources and preventing environmental disasters.

Monitoring a Water Pipeline. Image source: Madison Technologies

The combination of sensors and the cellular IIoT gateway can be repeated at multiple locations along the pipeline, and each gateway communicates with the host device, which can be located anywhere in the world.

Challenges and Opportunities in IIoT

The example of a water pipeline monitoring system illustrates the power of the IIoT. The system monitors the pipeline all along its length, 24x7, in a way that would be impossible otherwise. The performance of aeroplanes in flight can be monitored in the finest detail, perhaps averting disaster and certainly making improvements in performance possible. The potential for the IIoT is endless.

Humans can’t make decisions in microseconds, but computers can. People also can’t monitor multiple points in the radioactive sections of a nuclear power plant, make comparisons and determine if all is well or if very immediate action must be taken to avert catastrophe.

The IIoT will make finer control possible. That translates not only into greater safety but also into greater efficiency. At the time of this writing, billions of dollars are being earmarked for a new power grid, and the IIoT will make possible the split-second, continent-wide decision-making that will be necessary in order to inaugurate our new electric age.

As we reflect on the journey from ARPANET to the present day, it's clear that the IIoT is not just a technological advancement but a paradigm shift in how machines interact and operate.

The Future of IIoT

As we reflect on the journey from ARPANET to the present day, it's clear that the IIoT is not just a technological advancement but a paradigm shift in how machines interact and operate. Looking ahead, the integration of emerging technologies like Artificial Intelligence, Machine Learning, and advanced analytics will further enhance the capabilities of IIoT systems.

The future holds the promise of fully autonomous factories, smarter grids, and more efficient supply chains. With the advent of 5G and beyond, connectivity will become faster and more reliable, enabling real-time data processing and decision-making on an unprecedented scale.

However, with these advancements come new challenges, particularly in cybersecurity and data privacy. Ensuring secure communication between devices and protecting sensitive industrial data will be paramount.

The IIoT is set to transform industries and has the potential to impact society at large significantly. Embracing these technologies responsibly will be key to unlocking their full potential.

Key Takeaways

- IIoT has evolved from ARPANET to a cornerstone of Industry 4.0, reshaping industrial operations.

- It plays a crucial role in various sectors, from manufacturing to energy management, enhancing efficiency and decision-making.

- Emerging technologies like AI, 5G, and edge computing are set to further revolutionize IIoT capabilities.

- The future of IIoT promises even greater integration and innovation, impacting industries and society at large

References:

- What is IoT? Oracle: https://www.oracle.com/internet-of-things/what-is-iot/#industries-iot

- IIoT Examples and Use Cases by Industry in 2023. AirDroid: https://www.airdroid.com/mdm/industrial-iot-examples/

- What is Industry 4.0? Microsoft: https://www.microsoft.com/en-us/industry/manufacturing/resources/industry-4-0-technologies#what-is-industry

- Top 10 Industrial IoT Applications with Real-life Examples. NIX United: https://nix-united.com/blog/top-10-industrial-iot-applications-with-real-life-examples/

- Leveraging Cellular IIoT Gateways in Water and Wastewater Monitoring. Madison Technologies: https://madison.tech/leveraging-cellular-iiot-gateways/

Glossary:

- ARPANET: a research project that bloomed into the first packet-switched computer network

- IoT: a network of objects embedded with sensors and actuators that communicate over the Internet

- IIoT: A beefed-up subset of the IoT aimed at industrial or otherwise critical uses

- Transfer Control Protocol/Internetwork Protocol (TCP/IP): A universal communications standard for communication over the Internet