OceanGate Titan Submersible Failure: Consequences of Dodgy Engineering

Technical Analysis | 28-06-2023 | By Robin Mitchell

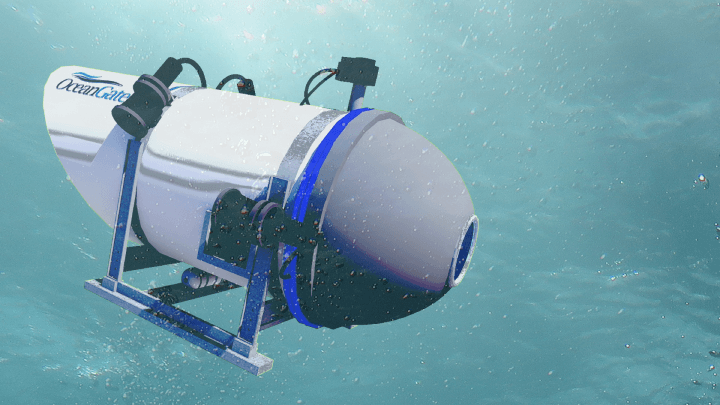

By Madelgarius, CC BY-SA 4.0, Link

To many, there was hope, but for those who understood submersibles, it was clear that the OceanGate Submersible Failure was doomed from the start. In this article, we will explore what happened with the OceanGate Titan submersible, a project of OceanGate Inc, what engineering flaws it suffered from, and why dodgy engineering gets people killed.

Table of Contents:

- The OceanGate Submersible

- The Engineering Behind the Ocean Gate Submersible

- The Carbon Fibre Hull – A Dangerous Choice

- Why Was Carbon Fibre a Poor Choice?

- The View Port – Short-Sighted Choices

- The Access Port – Trapped From Within

- The Ocean Gate Controller – A Child’s Game

- Off-The-Shelf Components – A Cheap Hack

- Young Engineers Over Experience – History Doomed to Repeat Itself

- The U.S. Coast Guard's Investigation

- How Dodgy Engineering Kills

"Years before OceanGate’s submersible craft went missing in the Atlantic Ocean with five people onboard, the company faced several warnings as it prepared for its hallmark mission of taking wealthy passengers to tour the Titanic’s wreckage." - New York Times

The OceanGate Submersible

For anyone with access to a smartphone, TV, or computer, it was nearly impossible to avoid the news of the OceanGate submersible. The vessel went missing shortly after communications were lost, approximately 105 minutes after deployment[1] (Reuters).

Founded in 2009, OceanGate has been at the forefront of manned submersible technology. The company's mission is to unlock the oceans for human exploration, enabling researchers, explorers, and private industry to explore, observe, and monitor the underwater world.

The history of submersible engineering has its roots in the early 20th century with the invention of the first practical submersible by French inventor Jules Verne. Since then, there have been several significant incidents involving submersibles, such as the sinking of the Kursk in 2000 and the Deepwater Horizon oil spill in 2010. These incidents underscore the inherent risks of underwater exploration and the crucial need for stringent safety standards, a lesson painfully reiterated by the OceanGate tragedy.

Despite the tragic incident with the Titanic submersible mission, it's worth noting that OceanGate has had a number of successful expeditions in the past. These include dives to Andrea Doria and the SS Governor, among others.

When the submersible went missing, desperate attempts were made to locate and rescue it. Numerous ships tried to identify any acoustic signature. The race to find the submersible intensified when banging was reported, sparking hope that the crew could be found before their oxygen supply ran out.

However, hope turned to despair when debris was discovered on the ocean floor, just a few hundred meters away from the Titanic wreck. The tailpiece of the submersible was found first, followed by the frame. It became clear that the submersible had suffered a catastrophic failure. While the media and many millions of watchers held onto the belief that the crew could have survived for several days, industry insiders knew that the submersible had likely imploded when communications were lost.

The catastrophic failure of the Titan submersible would have been swift and, in a gruesome sense, merciful. At pressures near the Titanic, a catastrophic implosion would have occurred in just one millisecond. The water would have collapsed the submersible at around 600m/s, approximately twice the speed of sound. The rapid compression of the air would have caused the internal temperature to ignite, instantly turning anything inside, including the crew, to ash. This phenomenon can be observed with fire starters that use plungers.

The once formidable vessel, a marvel of modern engineering, was reduced to a cloud of debris in an instant. The unforgiving depths of the ocean swallowed it whole, leaving behind only a haunting silence and a trail of unanswered questions. The crew, who had embarked on a journey of exploration and discovery, met a fate they could not have foreseen.

The Engineering Behind the Ocean Gate Submersibl

In this section, we will explore the engineering flaws in submersibles that led to the OceanGate disaster. To understand why the vessel failed, we need to look at the engineering behind the OceanGate submersible or the lack thereof[2] (Mirror). Despite the tragic outcome of the Titanic mission, it's worth noting that OceanGate has made significant contributions to underwater exploration. Their innovative approach to submersible technology has opened up new possibilities for ocean research and exploration. However, the Titanic mission's failure underscores the importance of rigorous safety standards and the need for experienced oversight in such high-risk endeavours.

Any engineer worth their salt understands that designing parts for extreme environments is no small feat, and there are exceptionally good reasons why such designs are expensive. Automotive-grade parts must be able to handle vibration and wide temperature changes so that vehicles provide both reliability and safety. Aerospace parts need to be able to withstand low pressures and high altitudes so that parts do not outgas and fail during flight, and parts used in medical implants must have no effect on living tissue.

When it comes to the depths of the ocean, the unbelievable pressures experienced are so great that defects in a structure containing a low-pressure environment (such as air at one atmosphere of pressure) can quickly collapse, crushing anything inside. For example, at pressures of 300 atmospheres, a 1 cubic meter of gas at 1 atmosphere would be crushed to a volume 1/300 smaller.

This means that engineers have to ensure that any and all parts used in a submersible are not only able to withstand those pressures but exceed them significantly to provide a good margin of safety. Therefore, submersibles are often designed using spheres, robust controls, multiple redundancies, and numerous safety features to prevent catastrophic implosions.

So, what features did the OceanGate incorporate to survive such depths? From the reports that have been surfacing, apparently none.

The Carbon Fibre Hull: A Dangerous Choice

Almost all submersibles use solid materials such as steel, and the reason for this is that such materials are homogenous, meaning that they have the same material properties in all directions. Therefore, it is very easy to model the forces experienced by a solid structure at any pressure, as the material’s behaviour is uniform from all sides.

However, the OceanGate submersible utilised a carbon-fibre cylinder which was not only a poor choice of shape, but unlike steel, carbon-fibre is not homogenous. Due to the use of fibres, the strength of carbon fibre varies, meaning that while it is strong in some directions, it is weaker in others.

In a shocking revelation, Stockton Rush, the CEO of OceanGate, admitted that the hull of the OceanGate Titan submersible was made with carbon fibre from a Boeing aircraft that was past its aeroplane shelf life. This information was reported by the Mirror, where Rush disclosed that he had acquired the carbon fibre at a "big discount" from Boeing due to its expired shelf life for use in aeroplanes. This raises serious questions about the integrity of the materials used in the construction of the Titan and the potential risks it posed to the crew.[2] (Mirror)

Credit: Yahoo News

The carbon fibre used by OceanGate was reported to have been sourced from Boeing but past its shelf-life, meaning that it was no longer fit for use in aerospace applications. As such, it is possible that the failure originated from an old material with non-uniform properties formed in a shape totally unsuitable for high-pressure environments.

To better understand the technical aspects, let's break down a few terms. A 'submersible' is a type of underwater vehicle that remains underwater for extended periods, unlike a submarine that surfaces frequently. 'Carbon fibre' is a strong, lightweight material used in various industries, including aerospace and automotive. However, its strength varies depending on the direction of the force applied, making it less suitable for certain applications. 'Homogenous materials' like steel have the same properties in all directions, making them easier to model and predict their behaviour under pressure.

Why Was Carbon Fibre a Poor Choice?

To understand why carbon fibre was a poor choice for the submersible's hull, we need to delve into the properties of this material. Carbon fibre is a composite material, meaning it is made up of two or more constituent materials with significantly different physical or chemical properties. In the case of carbon fibre, these materials are carbon atoms and a binding polymer. While carbon fibre is known for its strength and lightweight, these properties are not uniform across all directions. This is due to the alignment of the carbon atoms along the length of the fibre, which makes the material strong in the direction of the fibre but weaker in other directions. This anisotropic property of carbon fibre makes it less suitable for applications where uniform strength is required, such as a submersible hull designed to withstand high pressures from all directions.

The properties of carbon fibre that make it unsuitable for submersible hulls include:

- Anisotropic Strength: Carbon fibre has high strength in the direction of the fibre but is weaker in other directions.

- Non-uniform Properties: The strength of carbon fibre can vary depending on the direction of the applied force.

- Ageing Effects: Over time, carbon fibre can lose its strength and durability, especially if it is past its shelf-life.

The View Port: Short-Sighted Choices

At the front of the OceanGate submersible was a small viewport to allow the crew to see the surrounding ocean. While many submersibles integrate such viewports, the one used by the OceanGate sub was reportedly not suitable for use past 1,300 meters[3] New York Times). Considering that the Titanic is at a depth of 4,000 meters, the viewport introduces a potential point of failure. While the viewport’s manufactured rating would have been much lower than its true rating, a factor of 4 is still a massive margin over its stated rating.

Boasting a viewport with a diameter of 53 cm (21 inches), the Titan held the distinction of having the largest viewing window among all deep-diving submersibles, as per OceanGate's records.

The Access Port: Trapped From Within

The dome which housed the front viewport was made from titanium, which was likely suitable for the depths involved. However, the front dome, which is the only means of access to and from the submersible, is bolted shut from the outside, a design decision that has raised questions regarding emergency exit strategies. This means that in the event of an emergency, there is no way to get out, requiring engineers on the outside to unbolt the dome.

While this isn’t an issue for a deep-sea dive (as opening the hatch would be outright insane), issues occurring at the surface would essentially leave the crew trapped. Anyone who knows anything in the submersible industry recognises the importance of safety hatches and the ability to escape.

The Titan submersible, designed to accommodate a total of five individuals - one pilot and four crew members, was not exclusive to the ill-fated June 2023 expedition. It's important to note that the accompanying image does not depict the actual personnel aboard the vessel during its tragic final voyage. Oceangate

Finally, video footage showing the sealing between the spheres and the carbon-fibre cylinder suggests that an epoxy resin was used. While this may have been rated (little information surrounding this exists), epoxy resin can suffer from cracks over pressure and temperature changes. If the resin seal wasn’t checked with the use of X-ray systems (as is standard with such vessels), minute air bubbles and gaps could persist, presenting another mode of failure.

The Ocean Gate Controller – A Child’s Game

Among the design choices questioned by the media, the use of a Logitech F710 games controller as the sole means of control was frequently mentioned. While some have pointed out that many applications, including the military, use game controllers, the truth is that even in these applications, those controllers are built to a much higher standard. Furthermore, in instances where a game controller is used, secondary controls exist which are far more robust.

In the case of submersibles, a game controller could be useful for panning cameras operated by tourists or even allowing tourists to control the craft once at the location. But such a controller would never be the primary means of control so that in the event that the controller fails, reliable control systems can take charge and be used.

To make matters worse, the controller featured in the OceanGate submersible was wireless over Bluetooth. Any engineer who has dealt with Bluetooth will know how unreliable Bluetooth can be. It would not take much interference for commands from the controller to be misinterpreted or, worse, a force reconnect that could prevent control at a vital moment.

Off-the-shelf Components: A Cheap Hack

The submersible housed various electronic devices, including screens and lights. In interviews, the CEO of OceanGate disclosed that many of these components, particularly the lighting, were sourced from local camping stores. While the internal environment might accommodate such equipment, the associated safety concerns suggest these parts may not have been the most suitable choice.

Young Engineers Over Experience: History Doomed to Repeat Itself

The CEO of Ocean Gate opted for a team of younger engineers to design the Ocean Gate Titan rather than more experienced professionals. While this decision may have been driven by a desire for fresh perspectives, the absence of seasoned engineers with decades of experience could have contributed to the challenges faced by the project.

There is nothing wrong with having young engineers, everyone has to start somewhere, but in safety-critical applications, it is always essential to have a least one or two senior engineers with decades of experience. Younger engineers can present new ideas and methods that older engineers may not have thought of, but the experience of older engineers will ensure a level of safety and consideration that younger engineers simply don’t have.

According to a report by the New York Times, OceanGate was warned of potential 'catastrophic' problems with the Titanic mission. Experts both inside and outside the company had urged OceanGate to undergo a certification process, highlighting the potential dangers associated with the mission. Despite these warnings, the company proceeded with its plans, leading to the tragic loss of the Titan and its crew.[3] (New York Times)

The U.S. Coast Guard's Investigation

Following the tragic incident, the U.S. Coast Guard's Investigation was convened to look into the loss of the Titan submersible and its crew. The wreckage of the Titan submersible was located on the ocean floor, approximately 500 meters off the bow of the Titanic. The MBI, being the highest level of investigation in the Coast Guard, is working to determine the cause of the casualty, any acts of misconduct, incompetence, negligence, unskillfulness, or willful violation of law that may have contributed to the casualty, and whether there is a need for new laws or regulations to prevent the recurrence of such a casualty[5] (U.S.Coast Guard).

How Dodgy Engineering Kills

In this section, we will discuss the consequences of dodgy engineering, as exemplified by the OceanGate incident. Everything about the OceanGate submersible was a mistake, from the materials used to the technology integrated. The combination of poor planning, cutting corners, and refusal to obtain accreditation resulted in the loss of 5 lives.

Arnie Weissmann, the editor-in-chief of Travel Weekly, had a unique perspective on the Titan submersible. Although he never had the chance to ride in the Titan due to weather conditions, he spent a week aboard its support ship and had a close-up view of the operations. Weissmann recalled conversations with Stockton Rush, the CEO of OceanGate Expeditions, who assured him of the safety of the Titan's hull despite it being made from discounted carbon fibre past its shelf-life for use in aeroplanes. Weissmann noted Rush's dual nature - a meticulous planner and team leader on one hand and a cocky, self-assured pioneer on the other. In retrospect, Weissmann believes that Rush's overconfidence in his engineering skills and his perception of himself as a pioneer were his fatal flaws.[4] (Travel Weekly)

If there is anything that can be learned from this incident, it’s that following proper engineering practices and spending money on safety is essential for any project to be successful. The CEO of OceanGate thought that safety measures were limiting and unnecessary and that the rest of the submersible community was being dramatic for complaining about their design.

Unfortunately for the rest of the community, as far as the CEO was concerned, he was and always will be right. The speed at which the submersible imploded would have been so fast that he would have never known that he was wrong.

In the aftermath of the OceanGate submersible's failure, investigations were launched to determine the cause of the incident. The incident served as a stark reminder of the risks involved in pushing the boundaries of exploration and the critical importance of safety measures.

References:

- Reuters: Missing Titanic Sub: https://www.reuters.com/world/missing-titanic-sub..

- Mirror: OceanGate CEO Admitted Titan Subs: https://www.mirror.co.uk/news/us-news/oceangate-ceo-admitted-titan-subs..

- New York Times: OceanGate Was Warned of Potential for ‘Catastrophic’ Problems With Titanic Mission: https://www.nytimes.com/2023/06/20/us/oceangate-titanic-missing..

- Travel Weekly: Previous passengers recall ill-fated Titan: https://www.travelweekly.com/North-America-Travel/Previous-passengers-recall-ill-fated-Titan

- U.S.Coast Guard: Coast Guard convenes a Marine Board of Investigation for Titan Submersible: https://www.mycg.uscg.mil/News/Article/..