From Milk Film to High-Tech Wearables: The Rise of Ionogels

Insights | 26-05-2023 | By Robin Mitchell

While the film that forms on hot milk is generally unpleasant, some researchers have managed to gather inspiration from this material to create 2D ionogels that could help create future wearables. What challenges do hydrogels face, what did the researchers develop, and how could ionogels be useful for wearables in the future?

What challenges do hydrogels face?

Hydrogels have emerged as a promising material in the field of wearable devices due to their unique properties, including high water content, biocompatibility, and softness resembling human tissues. These characteristics make hydrogels ideal for applications such as biomedical sensors, flexible electronics, and smart textiles. However, despite their potential, hydrogels face several challenges that need to be addressed for their successful integration into wearable devices.

One of the primary challenges associated with hydrogels in wearable devices is their mechanical properties and durability. Hydrogels are typically fragile and prone to mechanical failure, limiting their long-term functionality. The soft and stretchable nature of hydrogels can lead to issues such as tearing, cracking, and delamination when subjected to repeated stretching or external forces. These mechanical challenges must be addressed to ensure the longevity and reliability of wearable devices.

Hydrogels can be utilised for sensing various physiological parameters, such as temperature, pH, and pressure. However, achieving accurate and reliable sensing performance in hydrogel-based wearable devices is challenging. The signal transduction from the hydrogel sensors to the electronic components requires efficient and stable interfaces. Maintaining a stable interface between the hydrogel and the sensing electrodes is crucial for accurate signal detection and interpretation. Additionally, minimising interference from environmental factors, such as sweat or body movements, is essential to obtain reliable measurements.

When developing wearable devices, ensuring biocompatibility and minimising adverse skin reactions is vital. Although hydrogels are generally biocompatible, certain formulations or additives may cause skin irritation or allergies. The prolonged contact of hydrogel-based sensors with the skin can also result in moisture accumulation and discomfort for the wearer. Strategies to enhance the biocompatibility of hydrogels and minimise skin interactions need to be explored to improve user comfort and safety.

Integrating hydrogels with electronic components also poses significant challenges. Hydrogels are primarily composed of water, making them incompatible with traditional electronic systems. The design and fabrication of electronics that can interface with hydrogels without compromising their functionality and performance is a complex task. Ensuring seamless integration of electronics, such as microchips, conductive wires, and power sources while maintaining the integrity and functionality of the hydrogel material remains a major hurdle.

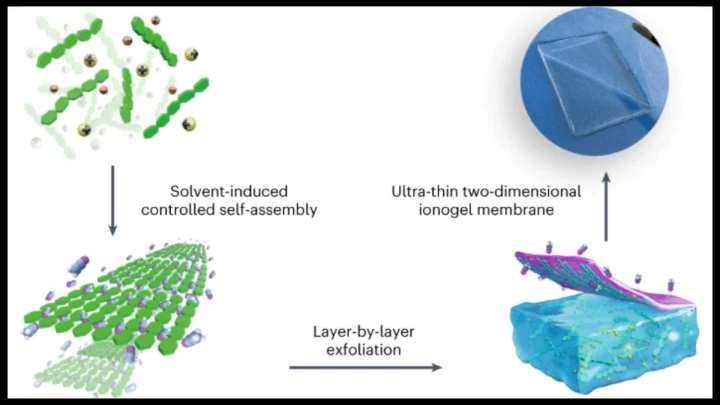

To overcome these hurdles, a team of engineers led by Professor Guihua Yu at the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and Texas Materials Institute have developed a novel "dip-and-peel" strategy. This strategy involves dipping sustainable biomass materials in certain solvents, causing the molecules to naturally arrange themselves into functional thin films at the edge of the material. These films can then be easily removed using a simple set of tweezers, a process inspired by the formation of a film on heated milk, a common phenomenon we often observe in daily life[^1^]

Researchers develop ionogel inspired by milk

Recently, researchers from Cockrell School of Engineering’s Walker Department of Mechanical Engineering and Texas Materials Institute have developed a new 2D material that could very well help power future wearable devices. The new material called an ionogel, is similar to hydrogels in that it is a flexible 2D structure capable of stretching and deforming without damage while providing potentially beneficial electrical properties.

The researchers were inspired by the film that forms on the top layer of milk to create the new material, as thin layers are easily grown and removed. Thus, the researchers looked at materials that can form thin layers that allow for easy separation and peeling. However, the material that the researchers developed does not have water surrounded by a polymer network, but instead, ionic liquids (hence the name). The resulting material is more flexible than hydrogels, and the use of an ionic liquid provides increased conductivity and is more sensitive to sensory inputs.

The ionogels created through this process are made up of a polymer network surrounded by ionic liquid, similar to the structure of hydrogels where water is the liquid element. However, ionogels feature a less rigid structure, giving ions more room to move around. This makes them highly conductive and very sensitive, with high potential as sensors for wearable electronics that could more accurately track motion, heartbeat, and other aspects of health monitoring2.

To create the material, the researchers utilised sustainable biomass materials and suspended them in certain solvents to create a dip and peel process. As the molecules rearrange themselves, the production process is trivial compared to other 2D thin films.

“This simple yet effective solvent-induced self-assembly method really allows rapid, and scalable production of 2D functional polymer films from different sustainable biomass materials including cellulose, chitosan, silk fibroin, guar gum, and more,” - Nancy (Youhong) Guo, lead author

How could ionogels be useful for future wearable devices?

By far, the most important feature of the new material is that its use of ionic fluid makes it far more conductive, thereby allowing for the creating of many electronic components. If the researchers can tune the conductivity, it could effectively allow for the creation of wearable flexible semiconductors, and this, in turn, could allow for advanced circuits to be formed.

At the same time, the use of ionic liquid also raises the possibility of the creation of better interfaces between electronic circuits and biosensors. The increased conductivity allows for such materials to be more sensitive to signals, thereby allowing for sensors to be made smaller. Thus, ionogels could be used to create miniaturised wearable medical devices.

What the researchers have developed is the start of a new material race, as the simplistic procedure will allow anyone to create their own ionogels. It won’t be long before we start seeing these materials used in other research papers and, hopefully, in commercial devices.

The major innovation in this research is not just the creation of ionogels, but the novel fabrication process that can be reproduced hundreds or thousands of times at high speed and low cost. The films can be easily manipulated to be as thick or thin as needed and shaped or coated to other materials. The research team hopes that other researchers will adopt this technique for various technologies, and they plan to further optimize the mechanical properties for more applications and advanced functionalities for next-generation technologies such as wearable electronics, smart robotics, and artificial intelligence3.