New Textile Sensor Breakthrough: Detecting Strain With Greater Sensitivity

In The News | 28-03-2023 | By Robin Mitchell

Researchers from ETH Zurich have made significant progress in the field of wearable electronics by developing a new textile sensor with greater sensitivity for detecting strain. This breakthrough was made possible by taking advantage of flexible technologies, conductive fibers, and capacitive strain gauges while also addressing challenges such as the Poisson effect and the need for auxetic structures like the helical thread structure with a negative Poisson ratio. The resulting passive sensors can wirelessly communicate with other devices, allowing for features like early fatigue detection and stride length and duration detection. What challenges do textile sensors face, what did the researcher develop, and how could they be used in the future?

What challenges do textile sensors face?

Despite the many advances in electronics, wearable devices continue to face numerous challenges. Of course, smartwatches have been available to the public for several years, and smart glasses are due to be released, but while these can be considered wearable, they are still bulky and cumbersome.

A device that is truly wearable would behave like clothes, moving with the body organically while not causing discomfort. But considering that the vast majority of electronics is based on ridged technologies, creating flexible circuits that can withstand extreme deformation while also surviving multiple washing cycles is extremely challenging.

Thankfully, thousands of researchers around the world continue to develop new flexible technologies that show real promise in the area of wearable electronics. For example, PragmatIC has demonstrated fully flexible ARM cores manufactured on flexible plastic substrates. At the same time, numerous universities have developed conductive fibres that can survive multiple wash cycles, and some have even created batteries that activate when exposed to sweat. But even with all of these advances, practical wearables are still a number of years away.

Researchers develop flexible strain sensors from textiles

Recently, researchers from ETH Zurich (University) have demonstrated a new strain sensor whose sensitivity is significantly higher than previously developed sensors. The resulting sensor was integrated into a pair of sports leggings, and the data from the sensor was streamed to a smartphone. From there, users could identify signs of early fatigue, thus indicating the best time to rest.

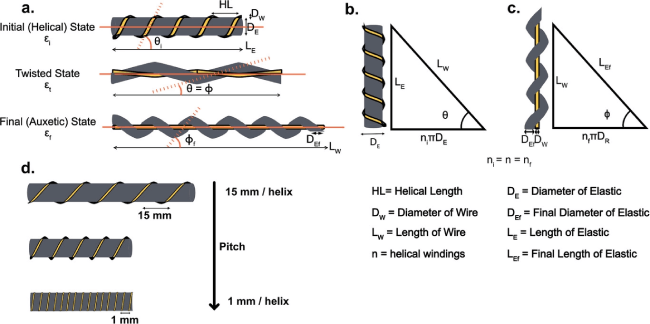

While capacitive strain sensors integrated into textiles is not new, what the researchers accomplished is a significant increase in sensitivity by exploiting auxetic structures. The basic concept behind capacitive strain gauges is that as a sensor is exposed to more strain, the distance between electrodes changes, and this causes a change in capacitance. However, typical strain sensors undergo a phenomenon called the Poisson Effect, whereby stretching a piece of material in one direction causes deformation in a perpendicular direction.

The best way to see this phenomenon is to stretch out a piece of rubber sheet. As the sheet is stretched, the material’s width is reduced, which negatively affects capacitive sensors, making them less sensitive.

To get around this phenomenon, the researchers turned to a helical thread structure that expands when stretched and contracts when compressed. This helical structure, which falls under auxetic structures, results in a material with a negative Poisson ratio, meaning that the material doesn’t experience perpendicular deformation under strain. Thus, the new sensor has a much higher sensitivity to strain.

a) The sensor is represented in three states: the initial state, the twisted state, and the final state. b) The initial state is represented geometrically. c) The final state is represented geometrically. d) The report tests the initial state of the HACS with various helical lengths.

How can textile sensors be used in the future?

One exciting feature that came from the researcher’s demonstration is that not only was the sensor integrated into a pair of sports leggings, but it didn’t require a power source fixed to the material. Instead, the sensor was entirely passive and connected to an antenna that wirelessly interacted with a smartphone that could easily be positioned in a pocket. At the same time, the sensor was able to detect changes in stride length and duration, which can be used as signs for detecting early fatigue.

Of course, this sensor alone won’t be able to usher new wearable technologies as numerous supporting devices and systems are needed. However, the work demonstrated by the researchers is certainly promising, and the use of helical structures to counteract the Poisson effect will certainly lead other researchers in a new direction when trying to increase the sensitivity of sensors.