MEMS Ideal Switch: High-Voltage, High-Current Control

Insights | 04-09-2025 | By Chris Keimel

Key Things to Know:

- EMRs: Proven and low-loss when closed, but slow, wear-prone, and require continuous coil power that wastes energy.

- Solid-state switches: Fast and durable in harsh environments, yet add losses and heat, lack true isolation, and complicate designs.

- MEMS switching: Chip-scale metal contacts deliver microsecond actuation, air-gap isolation, milliohm on-resistance, and microwatt control power for billions of cycles.

- Real-world impact: Enabling efficient protection and control from AI IC test to HVDC data-centre buses—e.g., a DIU/Menlo Micro 10,000 A, 1,000 V MEMS circuit breaker advancing through rigorous tests.

Chris Keimel, Chief Technology Officer, Menlo Micro

For more than 150 years, electromechanical relays (EMRs) have served as the workhorse of electrical switching, bringing society into an electrified world by connecting, controlling and protecting our powered devices and infrastructure. With electrical machinery operating in the order of seconds, there was never a need to make switches faster, just smaller and operate longer. As society advanced from a mechanised age driven by motors into an information age driven by data and its processing through chip-based devices, the need for speed began to take shape, first through our devices and more recently within our connected infrastructure through increased automation and smart electrical systems.

EMRs were never designed to meet the speed challenge. They were designed with simple criteria in mind, to be low-loss when on and isolated when open. EMRs rely on moving parts to change states; however, these moving parts wear with every operation, degrade with every arc event and become less reliable over time. In an era where energy efficiency is paramount, EMRs have another drawback besides speed; many require a few hundred milliwatts to a few watts of power to drive a coil that operates and keeps the contacts closed. This constant energy demand not only wastes power but also reduces the overall efficiency of the circuit.

Electromechanical relays are not the only way to control the flow of current; semiconductors are also used. While the first semiconductor devices were designed for signal amplification, it was not until the invention of the Integrated Gate Bipolar Transistor (IGBT) in the late 1970s that solid-state devices began to be widely adopted for high-speed control of electrical power. These devices, manufactured using semiconductor materials, aimed to address some of the limitations of EMRs, such as slow actuation speed, high noise levels and limited lifespan, were not designed to meet the full spectrum of performance demands within today's modern systems.

Consequently, these semiconductor-based switches have only been adopted in niche applications where millisecond and faster speeds are required, and millions and billions of operations are necessary because they trade off and lack the core capability of EMRs (low loss and isolation). Solid-state switches are used in harsh environments, where shock and vibration are present, where service and replacement are challenges, and where high operational counts are paramount. Solid-state switches introduce additional drawbacks that often add complexity to electrical systems. They do not fully isolate circuits as they have no air gap; they require additional thermal management as they are semiconducting and not fully metallic, and their body diode effect limits conduction in a single direction.

These limitations result in bulkier designs that detract from the chip-based miniaturisation of the switch, making them less desirable. Moreover, a semiconductor-based switch does nothing to solve the fundamental efficiency problems of electromagnetic relays; it is a more lossy solution because of both its semiconducting materials and the constant power required to drive the gates to activate the device.

From Electromechanical to Solid-State: Strengths and Limits

Recently, a completely new method of switching, based on microelectromechanical systems (MEMS), has emerged. MEMS technology is nothing new; these devices are around us performing everyday tasks without us realising their existence. They control your car's airbag deployment, sense tire pressure, and are the microphones in your handheld devices. They filter spurious communication signals and provide chip-based inertial stabilisation for autonomous platforms.

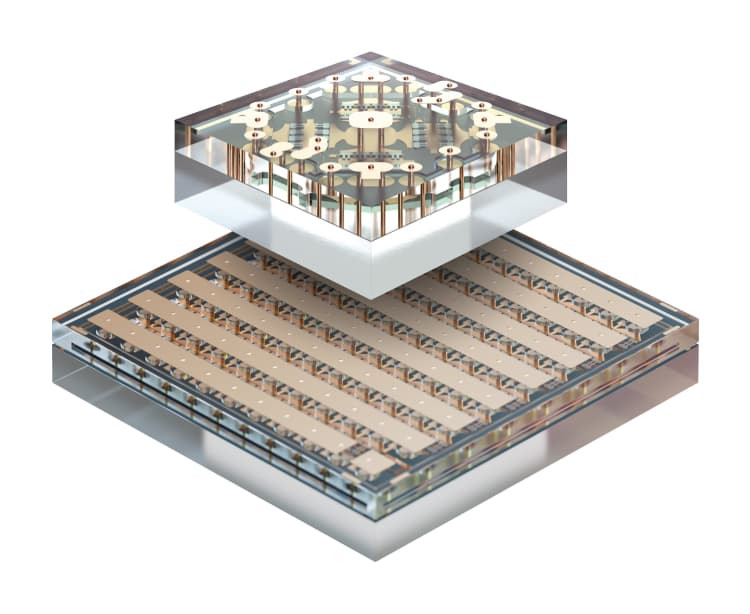

More recently, they are being used as miniature ohmic electrical switches deployed in wireless infrastructure and satellite communications links, and they are used to reconfigure advanced electrical test systems for some of today's most advanced CPU and GPU chips. (Update begins) In the mid-2000s, GE began its development of metal MEMS switch technology to bring microsecond switching speed to a truly low-loss ohmic switch in a chip-scale solution.

While others in the 1990s and 2000s were developing MEMS-based switch technology for low-power radio frequency signal switching applications, the GE team focused its development on power control and protection. A MEMS switch approach brings together the mechanical advantages of EMRs with the scalability of semiconductor-based technologies. Like an electromagnetic switch, it maintains metal-to-metal contacts, ensuring the best possible connectivity while the switch is closed. When open, an air gap provides the highest level of insulation. These MEMS switches are manufactured on wafers using existing manufacturing tools and techniques from the semiconductor industry that offer scalable volume manufacturing.

How is a MEMS-based mechanical switch able to operate in microseconds to mitigate a fault or reconfigure a circuit? The switches are tiny. They are 100 microns in size and therefore have little mass and are able to traverse an air gap in about 1 microsecond. Their spring forces are very high, and they have very stiff actuators with resonant frequencies typically greater than 100KHz. The control of these switches can be done using electrostatics, the application of a voltage creating an attractive force between two isolated plates to draw the plates together.

Why can a tiny microscale switch handle amperes of current? Individually, a single switch element can efficiently conduct a few 100 milliamperes of current. The switches are composed of metal alloys, and the contacts are made of traditional platinum family relay metallurgies that provide their ohmic behaviour and high conductivity while enabling mechanically robust, thermally stable and highly reliable operation. Their architecture is scalable on chip and enables tens to hundreds and even thousands of these tiny switch elements to be paralleled together in a few square millimetres within a chip to create a scalable architecture capable of controlling tens of amperes. This switch parallelism is familiar to the semiconductor industry, which fabricates millions of tiny transistors on a device within a circuit.

How can MEMS switches sustain 100s of volts across tiny air gaps with leakage currents of only a few picoamperes? The switches are manufactured and packaged through wafer bonding that encapsulates the switches in a clean gas-filled hermetic environment that is designed to minimise arc discharge and field emission. With field emission minimised, the microscale features take advantage of the lack of gas molecules across a microscale air gap that would typically cause an avalanche breakdown. This phenomenon is experimentally demonstrated in the Paschen curve, where hundreds of volts can be sustained across gaps of less than 5 microns. When processed on glass substrates, high-voltage structures can be fabricated in close proximity because surface leakages are minimised to picoamperes or less.

Efficiency, Scalability and Real-World Impact

To meet growing demand for greater electrification and point-of-load control, the latest MEMS-based switches are designed with scalability and integration in mind. They can be configured to handle higher voltage or increased current by combining devices in series or parallel, without significantly increasing the footprint. This enables engineers to tailor switching architectures to application-specific needs, supporting more flexible and compact system designs. At the same time, these switches offer the kind of long-term resilience that today's applications require. While traditional EMRs may provide around 100,000 cycles under cold switching conditions, and far fewer under load, this new class of switches can endure billions of operations. For edge computing, IoT deployments, and industrial systems operating in harsh or remote environments, this level of durability dramatically extends system life and reduces maintenance costs.

Importantly, MEMS-based switching also addresses the energy inefficiency at the heart of traditional technologies such as semiconductor-based switching technologies. By minimising both on-state resistance and off-state leakage, and by eliminating the need for constant current draw or heat sinks, these switches significantly reduce the thermal and power overhead typically associated with such switching elements. The metal construction enables milliohm chip cale devices in form factors in a fraction of the area of today's SiC JFET technology. The electrostatic drive control means the current consumption to control and actuate is a few microwatts, not milliwatts. This doesn't just improve performance, it also leads to simpler, smaller, and more energy-efficient designs.

Power inefficiency caused by excessive heat generation and dissipation no longer needs to be tolerated. Emerging switch technology, like the one described here, offers a new pathway: combining both electromechanical and semiconductor benefits in a scalable form factor, reduced weight, minimal power consumption, high performance and extreme longevity. These cumulative benefits are essential for current and future critical service power control applications in everything from the testing of AI ICs to enabling new high voltage DC bus architectures for data centers to even next generation smart control and protection systems for smart grid and industrial automation.

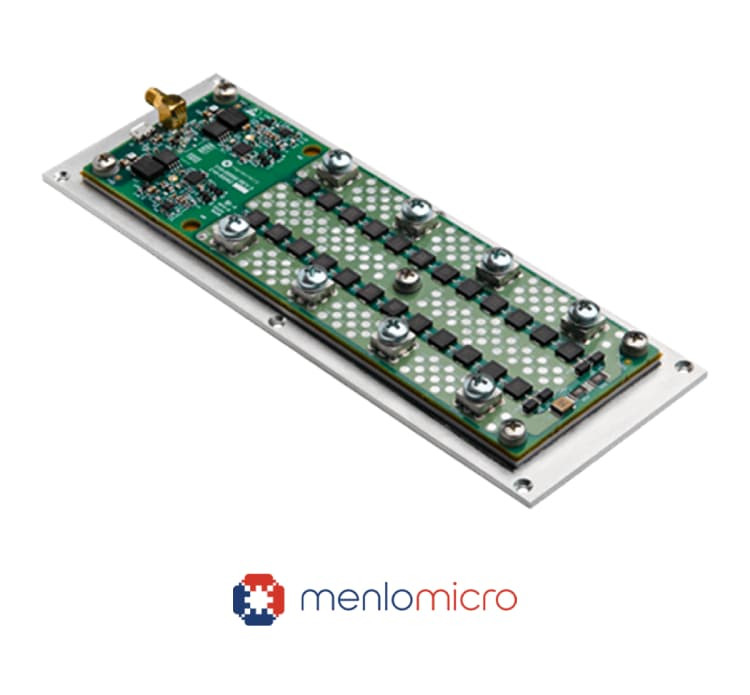

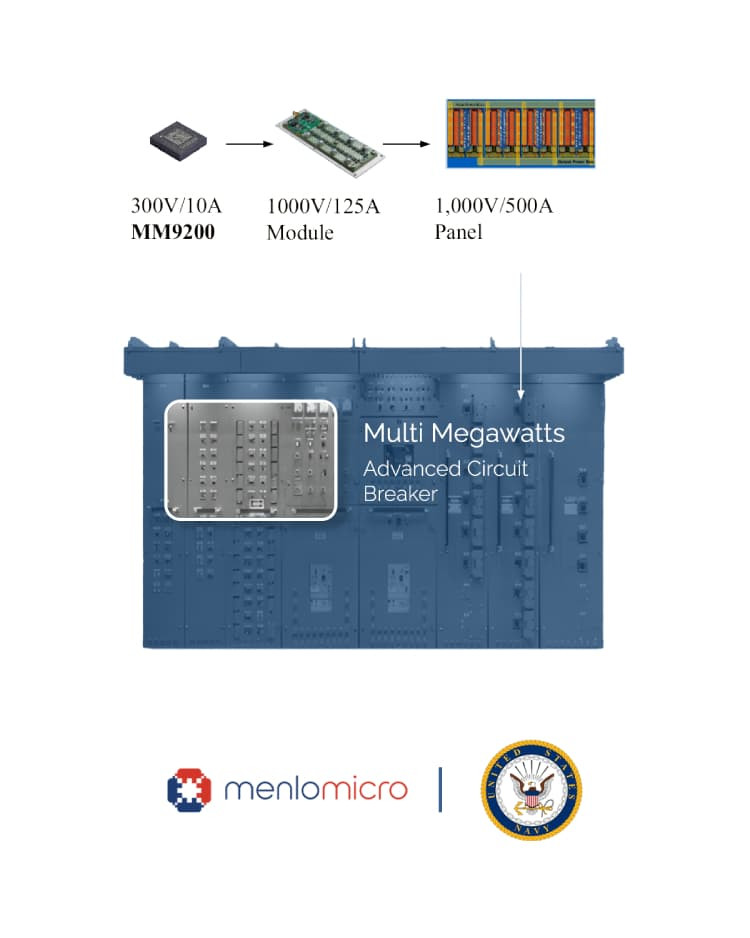

Real-World Deployment: 10,000 A, 1,000 V MEMS Circuit Protection

To provide an example of where MEMS switches are beginning to impact critical electrical infrastructure, Menlo Micro and the United States Defence Innovation Unit (DIU) are working together to develop a 10,000A, 1,000V circuit breaker for next-generation naval propulsion systems. The end product will feature multiple modules of Menlo's new MEMS-based switches. The project has successfully progressed through several project stages, delivering uniform current distribution across 500V and 100A switch arrays with minimal temperature rise during operation. The advanced circuit breaker project has also excelled in rigorous and stringent shock and vibration testing, making it ideal for military and high-reliability applications.

This combination of successful testing also makes the solution highly attractive to other industries that need high performance, reliability, low heat, reduced power consumption and durability throughout an extended lifespan, such as integrated circuit testing, satellite communications, factory automation or enhancing fault detection in energy infrastructure.

As system designers seek smarter, smaller, and more sustainable solutions, switching technology must keep pace. The future lies in high-performance, vastly reliable and very efficient switches that not only solve today's bottlenecks but also unlock new opportunities. Companies like Menlo Micro, leveraging MEMS-based innovations, are enabling industrial and high-tech customers to pioneer new power product designs, setting the stage for a new era of performance, energy efficiency, and scalable switching infrastructure. As demands on systems increase, this new class of MEMS switches offers a compelling path forward, one that builds on the past but is designed for the future.