Graphene Growth Drives Billions in Market Expansion

Insights | 03-09-2025 | By Paul Whytock

Key Things to Know:

- Market outlook: Graphene is shifting from startup novelty to global business, with value projected to grow from about €160 million today to roughly €1.8 billion by the mid-2030s, driven by high-volume uses and production advances.

- Manufacturing shift: MOCVD enables graphene to be deposited directly onto devices; researchers are now stacking other 2D materials (for example, molybdenum disulfide) alongside graphene to tailor performance.

- Real-world applications: rGO neural electrodes and graphene FET biosensors in healthcare, heat-spreading films in smartphones, high-power supercapacitors for EV energy recovery, and optoelectronic links that speed chip-to-chip communication.

- Key challenge: Cost and consistent supply of high-quality feedstocks remain limiting factors for large-scale, affordable production.

Graphene has moved on since its early entrepreneurial days to become a very lucrative, worldwide business with a projected value path that could see its worth grow from today's yearly value of approximately 160€ million up to 1.8€billion by the middle of the next decade.

Part of the reason for this growth rate lies in the increasing number of high-volume applications for graphene and some innovative breakthroughs in how the material is generated, which are in major contrast to how graphene started life.

Back in 2004 it was first formed by using Scotch tape to peel thin fragments from a chunk of graphite by Professor Andre Geim and Professor Kostya Novoselov at Manchester University. They discovered that graphene's 2D honeycomb structure is neither a metal, an insulator or a true semiconductor. Graphene is a semi-metal, similar to a semiconductor but with zero band gap.

Back to how it's produced today. UK company, Paragraf, for example, has developed a method of graphene production using an established semiconductor manufacturing process known as metal-organic chemical vapor deposition (MOCVD). Using this, the company can create graphene straight onto devices that need it.

From 2D Material Stacks to Real-World Graphene Applications

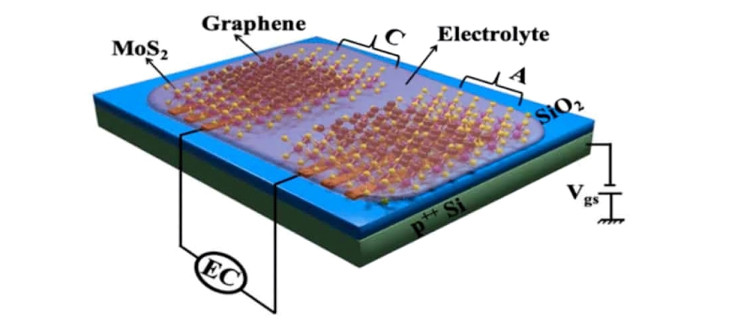

These graphene-based electronic devices include magnetic sensors and biosensor FETs. The plan going forward is to use MOCVD to deposit other 2D materials, such as molybdenum disulfide, into devices alongside graphene. Creating stacks of different 2D materials is now a research frontier because each material can bring specific operational characteristics and can also modify those of its neighbours.

As mentioned earlier, graphene's impressive acceptance is due to an increase in applications, both innovative and high volume.

For example, Spain's INBRAIN Neuroelectronics makes biocompatible rGO electrode arrays to measure brain activity, which could help clinicians distinguish healthy and diseased tissue when removing a tumour. The rGO (reduced graphene oxide) films are defined as graphene oxide (GO) with a decreased concentration of oxygen, achieved through chemical, thermal, or other means.

This reduction restores the hexagonal lattice structure and enhances the electrical conductivity of the material. That means these flexible implants, thinner than a human hair, can be smaller than conventional devices and offer a much more clearly defined diagram of neural activity, says company co-founder Jose Garrido of the Catalan Institute of Nanoscience.

The company has already gained recognition from America's FDA (Food & Drug Administration) for similar rGO electrode arrays that can stimulate the brain as well as recording it. A useful facility to help alleviate symptoms of Parkinson's disease.

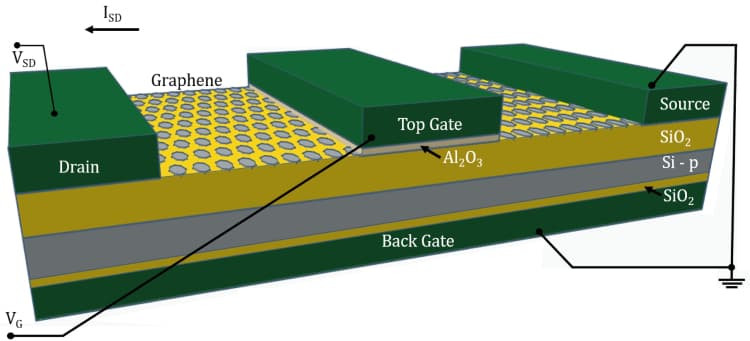

Figure: Schematic of a graphene-based dual-gate FET. Adapted from MDPI Micromachines, 2023.

Graphene also plays a part in the development of innovative sensor components. Graphene biosensors, for instance, are often based on field effect transistors (FETs), which can sense minuscule changes in electric fields. In a typical FET biosensor, the graphene has receptor molecules that bind to a target biomolecule, and this interaction changes the electrical current flowing through the graphene. INBRAIN is working on graphene FETs that would be even more sensitive than its rGO electrode arrays, capable of detecting the electric activity of individual

Moving East, a major producer of GOs and rGOs is the China-based Sixth Element (Changzhou) Materials Technology Company, which can produce about 1000 tons per year. In 2019, electronics company Huawei started to use Sixth Element's GO to draw heat from the circuits in its smartphones, enabling them to be thinner. Other phone brands quickly followed suit.

Graphene is also playing a major part in the design of super capacitors because of its excellent electrical conductivity and mechanical strength. Here's a breakdown of how it's used and why it's important.

Figure: Schematic representation of the MoS₂–graphene electrolyte-gated device. Source: Passive-Components.eu

Supercapacitors can store energy electrostatically and offer rapid charge/discharge capabilities. In addition they also have high power density, long cycle life but lower energy density compared to batteries.

Because of its high electrical conductivity, it provides fast electron transport, which is essential for quick charge/discharge cycles. It also features good mechanical strength and is flexible and chemically stable.

Monolayer graphene is also being deployed in optoelectronic devices, which rapidly convert light into electrical current and vice versa. Germany's Black Semiconductor, a partner in the Graphene Flagship, a research project that involves 170 academic and industrial research groups in 22 countries, is adding graphene to silicon microchips to speed up optical communication between chips. Ultimately, that means faster data processing, and recently the company secured more than €250 million in public and private funding to develop its devices.

Types of Graphene-Based Supercapacitors

Graphene’s versatility allows it to be used in different supercapacitor designs, each offering a unique balance of power density, energy storage, and performance characteristics:

- Electric Double-Layer Capacitors (EDLCs): These rely on pure graphene or reduced graphene oxide (rGO) as electrode materials. Energy is stored electrostatically through charge separation at the electrode–electrolyte interface, enabling rapid charge and discharge cycles with excellent efficiency.

- Pseudocapacitors: By combining graphene with metal oxides or conducting polymers, these devices add a faradaic (chemical) contribution to the charge storage mechanism. This allows for higher energy density compared to EDLCs, while retaining graphene’s high conductivity and stability.

- Hybrid Capacitors: These integrate graphene with traditional battery-type materials, creating a balance between the high power density of EDLCs and the higher energy density of batteries. As a result, they offer both fast charging capability and extended energy storage.

Global application

A high value market for supercapacitors is electric vehicles (EVs) which is not surprising when looking at the global growth rate of EV sales. The market is expected to reach over €700 million by 2026 and is estimated to grow at a CAGR of 19.4% through to 2030.

An important application for supercapacitors in EVs is the efficient generation of electrical energy through brake energy regeneration. One car maker using this technology is Mazda.

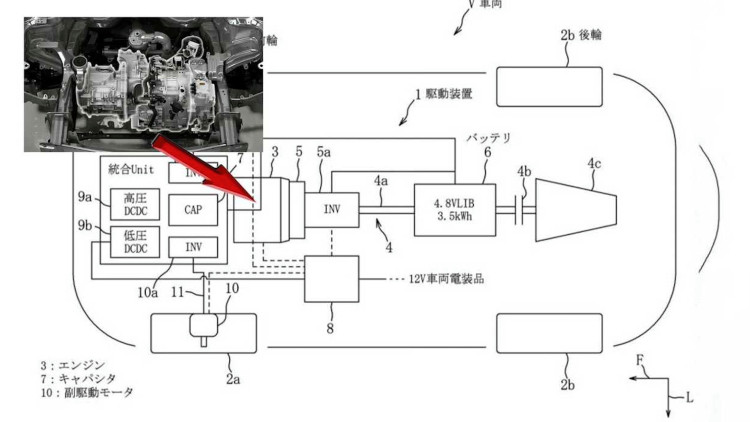

Figure: Mazda patent diagram showing integration of a capacitor system to improve efficiency in EV drivetrain architecture. Source: InsideEVs.

According to Mazda, the system continuously recovers kinetic energy as the vehicle decelerates. It does this with a variable voltage alternator that charges a supercapacitor, which powers the vehicle's 12V electrical equipment and accessories, offloading the battery. The alternator varies its output voltage between 12V and 25V in response to the capacitor's voltage, which is related to its state of charge.

The system switches the alternator off when the driver presses the accelerator, leaving the supercapacitor to power the electrical system so that less engine power is needed to achieve the level of acceleration that the driver demands, thereby reducing fuel consumption.

Figure: Lamborghini Sian FKP 37 coupe featuring integrated graphene-enabled supercapacitor technology to boost performance. Image courtesy of Lamborghini.

Even Lamborghini is sold on the role of supercapacitors with the Sian FKP 37 coupe featuring them in conjunction with an electric motor to enhance the performance of its 774hp 6.5-litre V12 engine.

So, the future of supercapacitors looks financially good, but there are graphene design problems that need to be addressed. One of them is the cost of producing them because graphene itself is not cheap.

This is because the raw materials for graphene production are expensive, and it's not always easy to find a reliable, constant source of high-quality materials that are essential for high-volume production. This then is a very real industry challenge, given the high production requirements needed to meet the accelerating global growth rate of innovative graphene applications.