Whitepaper: Miniature Sensor Interconnections for Rugged Applications

Technical Analysis | 05-03-2024 | By Omnetics Connector Corporation

Introduction

Sensor systems are becoming a primary data source on highly portable electronic technologies employed in potentially extreme environmental conditions and must be small, lightweight and rugged. The interconnection networks within those systems have evolved by using micro and nano-sized interconnection techniques.

Advancements in Device Technology and Applications

New device technologies and chip developments have greatly extended the opportunities to use multiple sensors within one coordinated interface network. They detect, process data and support communications from module to module such as those working together on Net Warrior and Future Soldier applications. These also interface with mounted and unmanned roving vehicles within the battlefield. Further extensions of this technology are exhibited in new electro-optic sensors and in onboard controls for unmanned aerial vehicles. Recent additions, as well, are now being integrated into new ballistic devices for both remote and self-guidance control. Sensors are employed and perform superbly on satellite systems. We also see new sensors in many neural modulation devices, such as new cochlear hearing and pain modulation in our medical industry.

Sensor Applications Across Industries

Sensor device applications have expanded the world from daily activities to those being operated remotely in deep space. The automotive, military and aircraft industries have helped sustain growth in sensing options and methods. We have nano-sized connectors designed for rugged low-profile currently functioning on sensor systems on the Mars Rover. The “Curiosity” weather sensors detect and deliver air temperature, ground temperature and report atmosphere humidity on the planet that is streamed back to monitors on Earth.

Evolution of Optical Systems and UAVs

Optical systems evolved from the light meters and sensors of yesterday but are now made with photon chip collectors that can include multi-spectral and hyper-spectral collectors and imaging. They collect multiple wavelength bands of light and combine them into an overlaced image. This method also provides wider ranges of infrared radiation detection used for tracking defence-related devices such as onboard the missiles in flight and onboard the MQ-4C Triton broad area maritime surveillance system (BAMS). LIDAR (light imaging and detection) systems on planes and orbiting satellites have extended the older RADAR systems as they can see down through atmospheric and ground cover to offer geophysical mapping and control systems beyond GPS.

The Role of Sensors in Military Applications

Hand-launched drones and UAVs are being extended from personal to military and onto commercial surveillance data collection. UAVs provide an improved value in surveillance and offer close control for monitoring wide-area moving target indicators (MTIs), ground targets, and airborne early warning (AEW) radar surveillance in support of theatre missile to ground defence. The usual aircraft sensors for altitude, GPS positioning and guidance, and aileron control, the sensors must be small, lightweight and rugged enough to function continuously during constant vibration and thermal changes. Often, they are squeezed into unique shapes and tiny spaces to support the minimum size and weight needed for hand launch and or to be small enough to avoid visual detection from the ground.

Future Soldier Technologies

Dismounted warriors remain in constant contact with battlefield control centres through use of new “Future Soldier” worn sensors (NVESD), night vision and electronic directorate systems to report and track field data. The helmets have been redesigned to feature two visors (splinter proof and bullet proof) as well as helmet-mounted displays (HMD) capable of displaying information from a low-level TV camera mounted on the back of the helmet. Black Diamond’s APEx is a modular, wearable system which consists of a controller for both power and data distribution, a tablet computer, as well as a number of IP68 cabling options specifically designed to connect to other devices commonly used in the field. Designers of the APEx (advanced prototyping and experimentation) system required rugged, mission-critical miniature cables and connectors to provide the interconnect solutions for a number of peripheral cables as well as the main power cable.

Robotics and Exoskeletons in Military and Industrial Use

Robotic devices, machinery, and exoskeletons have found their way out to the “End-Of-Arm” (EOA) in many instruments to significantly enhance touching, and handling previously difficult functions. Electronic designers are moving computer chips and sensors out to the extremities of the robotic arm that is used for pick and placement of minute sizes and somewhat fragile items. With the use of optical sensing equipment, the newer industrial machines can do multiple manufacturing steps that were previously relegated to hand assembly done under microscopes. Sensors detect pressure and can control mechanized pick and squeeze motions of delicate items without damage. Our armies are adding similar technology in the form of exoskeletons that can improve the current physical capabilities of a war fighter, allowing him to run faster, lift heavier objects, and relieve personal strain when needed. Industrial robotics are using sensors to offer machine learning and sharing that to automated assembly lines.

Satellite and Cube Satellite Sensor Technologies

Satellite sensors help control the position and direction of the satellite itself, as well as scan, collect, and measure data from optical and chemical information to a range of radio and infrared frequencies. On-board star trackers photograph and map the positions of various stars to help maintain the attitude concerning their geostationary orbit. Research satellites travelling to far-away places also use star-tracker mapping and reference data for navigation. These devices and interconnection systems are potentially vulnerable to light and radiation interference in addition to constant shock and vibration during travel.

Miniature Connectors and Interconnection Systems

Interconnection systems in sensor applications often depend upon miniature connectors and wiring running out to and from the equipment segments. As robotic devices evolve to more delicate and sensitive capabilities, we are including wiring systems to the machinery. The cable and connectors used must be extremely small and lightweight while maintaining extreme ruggedness. One solution includes the use of the Metal-Nano-D connector. The connectors are built to meet Military Specifications @ .025” pitch and survive a range of ruggedness and performance tests useful in automated machinery. Board-mounted versions mate up with pre-wired connectors/cables for instrument wiring. Temperature ranges can exceed +200ºC, and locking screws or latches hold things together during machine operation. New equipment most often includes new devices and performs unique functions. This process of configuring connectors to application-specific begins with a review of the equipment to which the connectors will be applied. Standard and COTs connectors can be considered and analyzed to find a close fit to the new application. During the early stages of design, COTs connectors can be used in prototype circuits, which can save time and cost of development. There are significant advantages when the COTs, or even small changes to the COTs connectors, will suffice. Connectors with previous military-quality materials and processes can shorten the design cycle time and give early expectations of lifespan and performance. When changes in shape or size are required, a solid model of the new design can be quickly completed by the connector supplier and sent to the system design team. This can begin an online work session that also helps to get the design right early in the process. After design completion, connector fabrication can be transferred directly to smart tooling machines.

Design and Planning of Sensor Cabling

Planning sensor cabling and interconnection routing significantly helps in the design of the whole system. Again, size, weight, insulation, shielding, and even flexibility can be critical and or a problem, if not planned ahead of time.

Challenges in High-Speed Signal Processing

Signal and power to the cable as signal speeds increase can be very critical. Higher speed differential signal processing pushes the limits of standard cables in our industry. Signal length, attenuation, and skew of differential signals must all be planned, prescribed, and attended to in the cable design.

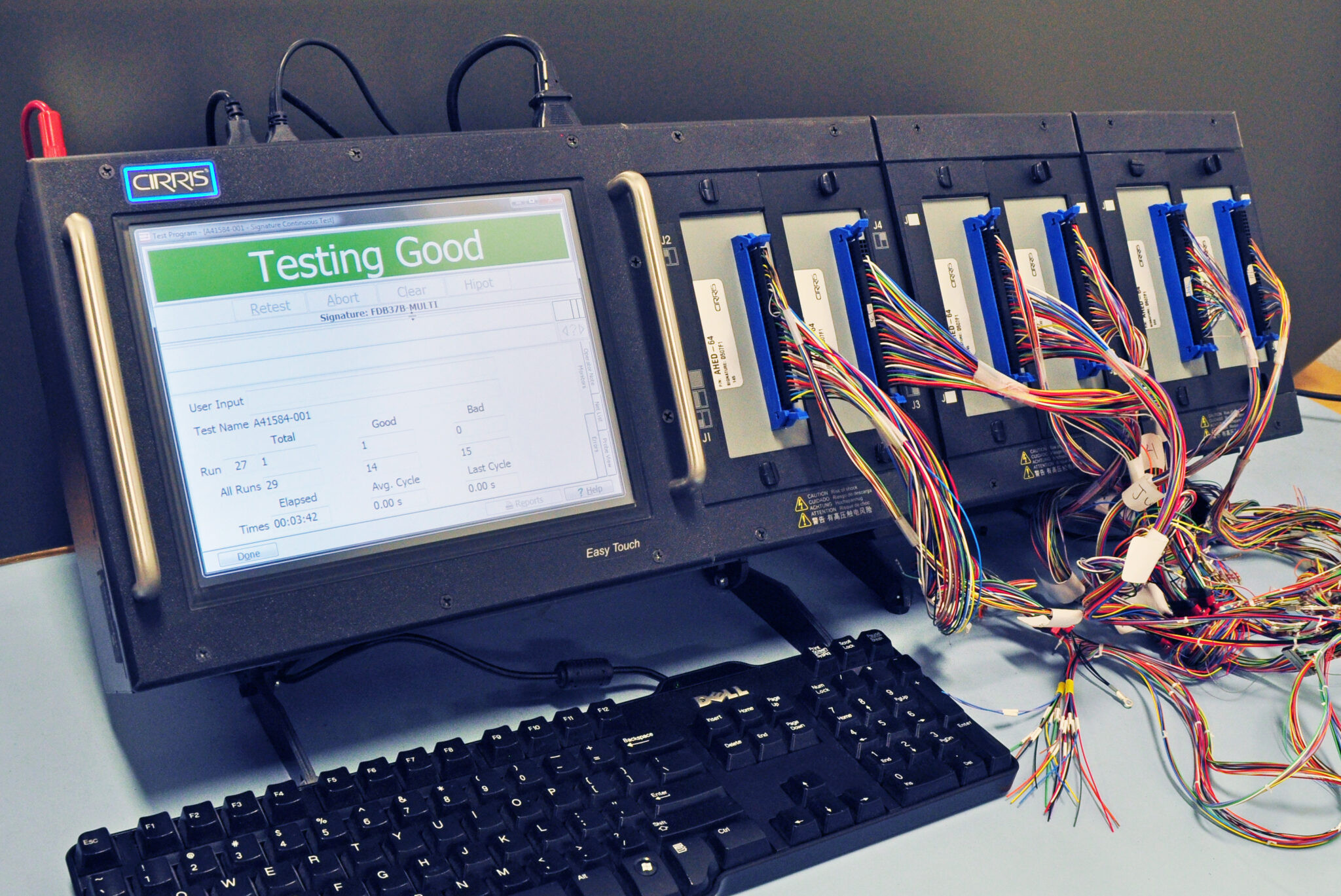

Importance of Testing and Certification

Final electrical and mechanical testing can ensure good performance of the completely assembled connector to the cable harness. Field-proof testing and certification will require building enough of the products to run the group through combinations of mechanical, environmental, and signal integrity performance.

Advancements in Connector and Interconnection Technology

Many standard designs are off-the-shelf at reasonable costs. Nano-sized industrial interconnect systems are helping the explosion of sensor use from satellites to home-based devices. High-reliability pin and socket systems using spring beryllium copper or twisted steel to retain constant contact. In addition, the pin/socket set must be plated with nickel and then gold to help retain contact reliability over long exposures. Test specifications are defined to qualify and ensure reliable performance. Many applications will require metal back shells and braided metal shielding over the cable to prevent both damage and EMI (electromagnetic interference shielding). As digital signals operate at a lower voltage and as speeds increase, we can squeeze more electronics into tighter spaces. Preplanned sensor design and interconnection routing have become critical. Application design support is available online directly from your connector design supplier. The Fast Turn-Design team at Omnetics can share solid models and change size, shape and connection routing on the fly to save time and money in your next sensor circuit.

For more information, please contact us or visit https://www.omnetics.com/.