What is an Electrical Connector? In-Depth Look into the World of Connectors

Educational | 24-07-2023 | By Jack Pollard

This article provides a comprehensive overview of electronics connectors, their types, components, and applications. It also discusses the challenges faced by connectors in various environments and the solutions to these challenges.

Table of Contents

- Introduction

- Types of Connectors

- Common Types of Connectors

- The Three Main Types of Connectors

- The Most Common Type of Electrical Connector

- Diving Deep into the Anatomy of a Connector

- Connector Selection Criteria

- Connectors for Challenging Environments: IP Ratings

- Applications of Connectors

- Future Trends in Connector Technology

- Conclusion

- References

Introduction

Connectors, often overlooked, are the linchpins of the electronics industry, enabling seamless connections between various pieces of equipment. They come in a myriad of forms, from the ubiquitous USB connectors to the internal links within desktop PCs, ensuring reliable transmission of signals and power. In this comprehensive guide, we delve into the captivating world of connectors, exploring their common types, essential components, and the crucial role they play in both everyday and challenging environments.

Types of Connectors

The connector universe is vast and diverse, encompassing a multitude of types, each with unique features tailored to specific applications. Among them, external connectors like USB, HDMI, and mobile phone chargers are some of the most common examples. These connectors undergo frequent insertion and removal cycles, necessitating mechanical robustness to withstand prolonged usage.

Let's delve deeper into the different types of connectors:

- USB Connectors: Universal Serial Bus (USB) connectors are widely used in computers and other digital devices for data transfer and power supply. They come in various forms, including Type-A, Type-B, Mini USB, Micro USB, and the latest Type-C.

- HDMI Connectors: High-Definition Multimedia Interface (HDMI) connectors transmit high-quality video and audio signals. They are commonly found in televisions, monitors, and audio devices.

- Power Connectors: These connectors deliver power from a source to a device. They come in various forms, including IEC connectors and NEMA connectors, each designed for specific power requirements.

- Audio and Video Connectors: These connectors, including RCA, VGA, and DVI, are used to transmit audio and video signals. They are commonly found in entertainment and audio-visual systems.

- Data Connectors: Data connectors, such as Ethernet and SATA, are used for data communication in networks and storage devices.

- RF Connectors: Radio Frequency (RF) connectors are used in wireless communication systems, including Wi-Fi and satellite systems. Examples include BNC, SMA, and N-Type connectors.

Each type of connector is designed with a specific purpose in mind, and understanding their differences is crucial in selecting the right connector for your application.

The Three Main Types of Connectors

Connectors can be broadly classified into three main types: temporary, semi-permanent, and permanent. Each type has its unique characteristics, applications, and examples, which we will explore in detail:

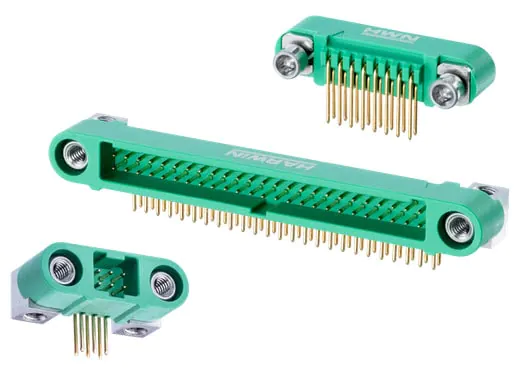

Figure 1: The Harwin Gecko-SL, as shown, employs a sturdy screw-lok connection, providing easier access, more secure fastenings, and options for panel-mounting. (Source: Mouser Electronics)

1. Temporary Connectors

Temporary connectors are designed to be easily connected and disconnected without the need for tools. They are commonly used in applications where frequent connection and disconnection are required. Examples of temporary connectors include USB, HDMI, and Ethernet connectors.

USB connectors, for instance, are used to connect devices like printers, scanners, and external hard drives to computers. HDMI connectors are used to transmit high-definition video and audio signals between devices such as televisions, monitors, and gaming consoles. Ethernet connectors, on the other hand, are used to connect computers to a network.

2. Semi-Permanent Connectors

Semi-permanent connectors require some form of tool for connection and disconnection. They are typically used in applications where the connection needs to be secure but may need to be disconnected at some point. Examples of semi-permanent connectors include those found in computer peripherals, such as the connectors used to connect a motherboard to a power supply or hard drive.

These connectors often have a locking mechanism to ensure a secure connection. For instance, the SATA connectors used to connect hard drives to the motherboard have a small latch that locks the connector in place when inserted.

3. Permanent Connectors

Permanent connectors are intended to remain in place for the life of the device. They are used in applications where the connection should not be broken under normal circumstances. Examples of permanent connectors include soldered connectors on a circuit board, or the connectors used to connect components within a smartphone.

Soldered connectors, for instance, are used to make a permanent, electrically conductive connection between components on a circuit board. These connectors are soldered directly onto the board, creating a strong and reliable connection that can withstand the rigours of use.

The Most Common Type of Electrical Connector

The most common type of electrical connector is the pin and socket connector, also known as a plug and receptacle connector. This type of connector is used in a wide range of applications, from consumer electronics to industrial machinery and even in aerospace and military applications.

The pin and socket connector is designed to provide a reliable and secure connection, with the pin (male) component inserted into the socket (female) component. The male component, or the pin, is typically a protruding piece that fits into the female component, or the socket, which is a receptacle for the pin.

These connectors are designed to maintain a strong connection, often with a locking mechanism to prevent accidental disconnection. They are also designed to withstand a variety of environmental conditions, with some variants offering features such as waterproofing or resistance to high temperatures.

In terms of their construction, pin and socket connectors can be made from a variety of materials, including brass, copper, and even gold, depending on the specific requirements of the application. The choice of material can affect factors such as the connector's durability, conductivity, and resistance to corrosion.

Overall, the pin and socket connector's versatility, reliability, and wide range of applications make it the most common type of electrical connector in use today.

Diving Deep into the Anatomy of a Connector

Connectors are ingeniously designed, comprising several essential components to ensure optimal performance. Each part plays a vital role in the overall functionality of the connector, contributing to its durability, reliability, and efficiency. Let's delve deeper into these components:

- Connector Pins: These are the heart of any connector. They carry both signals and power, forming the lifeline of the connection. The pins are typically made of a conductive material like copper or brass, often coated with a layer of gold or nickel to enhance conductivity and resist corrosion. The number and arrangement of pins can vary widely, depending on the specific requirements of the connection.

- Housing: This is the protective shell of the connector, holding the pins in position. The housing not only provides mechanical support but also ensures that the pins are correctly aligned for connection. It is usually made of a durable material like plastic or metal to withstand the rigours of regular use.

- Strain Relief: This component safeguards the attached cable from stress and strain during usage. By providing a flexible link between the cable and the connector, strain relief helps prevent damage to the cable and ensures a stable connection, even when the cable is bent or twisted.

- Shielding: This is essential for preventing electrical noise and ensuring reliable data transmission. The shielding acts as a barrier that blocks electromagnetic interference, which can disrupt signal transmission. This is particularly important in connectors used for data or signal transmission, where even a small amount of interference can lead to significant data loss.

- Mechanical Keying or Polarisation: This feature facilitates correct connection and prevents mismatches. By ensuring that the connector can only be inserted in one way, mechanical keying prevents damage to the pins and ensures a secure connection. This is particularly important in complex connectors with multiple pins, where an incorrect connection could lead to short circuits or other issues.

Connector Selection Criteria

Choosing the right connector for a specific application can be a complex task, as it involves considering a variety of factors. Here are some key criteria to consider when selecting a connector:

- Number of Contacts: The number of contacts or pins a connector has can determine the number of signals or power lines it can handle.

- Type of Termination: The termination method, such as soldering, crimping, or insulation displacement, can affect the ease of assembly and the reliability of the connection.

- Current Rating: The maximum current a connector can carry is a critical specification, especially for power connectors.

- Voltage Rating: The maximum voltage a connector can handle without breaking down is another important factor, particularly in high-voltage applications.

- Operating Temperature: The range of temperatures a connector can withstand during operation can determine its suitability for certain environments.

Connectors for Challenging Environments: IP Ratings

In industrial or outdoor settings, connectors face a multitude of challenges. They are exposed to harsh conditions and a variety of environmental factors like liquids, gases, dust, and other contaminants. These demanding environments require connectors that are robust, durable, and capable of maintaining reliable connections despite the adversities they face.

For such applications, connectors with Ingress Protection (IP) ratings, such as IP67 or IP68, are often utilised. The IP rating system is a standard that defines the levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies (tools, dirt, etc.) and moisture. The first digit in the rating indicates the level of protection that the enclosure provides against access to hazardous parts and the ingress of solid foreign objects. The second digit indicates the level of protection of the equipment inside the enclosure against harmful ingress of water.

For instance, an IP67-rated connector is completely dust-tight and can withstand temporary immersion in water, while an IP68-rated connector is dust-tight and can be continuously submerged in water under conditions specified by the manufacturer. These connectors are equipped with seals and locking mechanisms to prevent the ingress of moisture and contaminants, ensuring reliable performance even in the most challenging environments.

Before these connectors are deemed suitable for use, they must pass rigorous tests to ensure compliance with their respective IP ratings. These tests often involve exposure to dust, high-pressure water jets, and even prolonged submersion in water. Only after successfully passing these tests can a connector be certified with an IP rating and considered fit for use in challenging environments.

In conclusion, when it comes to challenging environments, the choice of connector is crucial. The right connector, with the appropriate IP rating, can ensure the reliable and uninterrupted operation of equipment, contributing to the overall efficiency and productivity of industrial and outdoor applications.

Applications of Connectors

Having explored the various types and components of connectors, let's now delve into their practical applications, starting with the versatile role of internal connectors.

The Versatility of Internal Connectors

Within the confines of electronic devices, connectors take on a different role, often carrying numerous connections. They are the unsung heroes that ensure the smooth operation of the device, enabling communication between different components and facilitating the device's overall functionality.

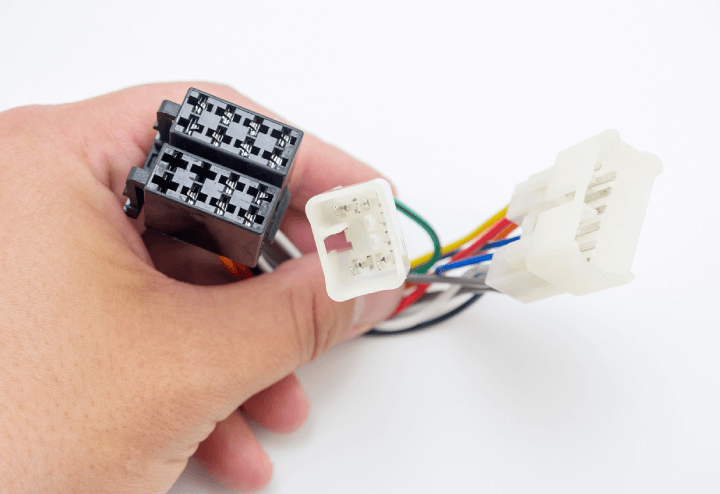

These connectors are found inside a wide range of products, from desktop PCs to tablets and laptops. They enable various types of connections, including board-to-board, wire-to-board, and box-to-box connections. These internal connectors are crucial in transmitting power and data within the device, ensuring that each component can perform its function effectively.

Internal connectors come in a variety of shapes, sizes, and pin counts, each designed to suit the specific application. For instance, a desktop PC might use a 24-pin ATX connector for its main power supply, while a laptop might use a smaller, proprietary connector for its internal battery. The design of these connectors often incorporates locking mechanisms to ensure a secure connection and prevent accidental disconnections.

Moreover, these connectors are designed with polarisation features to prevent incorrect connections. This is crucial in ensuring the safety and longevity of the device, as incorrect connections can lead to short circuits, component damage, or even fires.

In conclusion, internal connectors may not be visible or prominent, but they play an essential role in the operation of electronic devices. Their versatility and adaptability make them a vital component in the world of electronics.

Two Common Types of Power Connectors and Their Use in Space Applications

Power connectors, as the name suggests, are used to transmit electrical power. The two most common types of power connectors are the IEC connector and the NEMA connector. The IEC connector is used worldwide and comes in a variety of types, each designed for a specific application. The NEMA connector, on the other hand, is primarily used in North America and comes in both locking and non-locking varieties.

In demanding environments such as space, the choice of power connectors requires extra considerations. The space environment introduces additional factors such as vacuum, cosmic and thermal radiation, the cost of pushing mass away from the Earth’s gravity, space (volume) allowance in a rocket, vibration at launch, and the cost of failure and repair. These factors must be factored into the connector choice.

For instance, the lack of air in space affects the maximum voltage rating of connectors. Flashover, the moment of flashover from a conductor to the nearest metal item, will occur at a different voltage depending on the air molecules’ density. Therefore, connectors with a voltage rating for altitude are required. Additionally, outgassing or offgassing, the release of gas dissolved, trapped, frozen, or absorbed in materials, introduces contaminants into the equipment, which might cause problems during the life of the product. Both NASA and the European Space Agency (ESA) specify recommended volume levels of outgassing for materials used in their space applications.

Cosmic radiation becomes a problem as altitude increases and our protective atmosphere thins. The effects are similar to electromagnetic interference (EMI) in ground-level electronics, and the solution is the same: shielding. Thermal radiation also increases when a space vehicle is in direct sunlight with no atmosphere, but the temperature can also drop to very low levels in shadow or even on the vehicle’s side away from the sun. Therefore, connectors must be specified for maximum and minimum temperature range during operation.

Every gram pushed into space from the Earth’s surface costs money. More mass equals a bigger vehicle, which requires more fuel. Both volume and weight carry penalties. Therefore, connectors in the performance bracket needed should also be the smallest and lightest possible. The launch is a high-vibration, high-acceleration environment, so connections need to survive this period intact and still mated. Therefore, connectors rated for vibration, shock, and acceleration are required.

Finally, the cost of failure and repair is a significant consideration. Depending on the mission, a failure could cause a loss of human life or a costly setback. Therefore, connector requirements should be set based solely on performance requirements.

Future Trends in Connector Technology

As technology continues to evolve, so too does the world of connectors. Here are some emerging trends to watch:

- Miniaturization: As devices become smaller and more compact, there is a growing demand for smaller connectors that can still deliver reliable performance.

- Increased Data Rates: With the rise of high-speed data applications, connectors capable of supporting higher data rates are becoming increasingly important.

- New Applications: Emerging technologies such as electric vehicles and renewable energy systems are driving the development of new types of connectors.

Conclusion

As we draw to a close, we celebrate the vital role connectors play in uniting the world of electronic devices. From facilitating communication between external equipment to ensuring seamless internal connections, connectors bring the magic of interconnectivity to life.

This article was brought to you by Mouser Electronics with help from Samtec.

With an incredible range of connector solutions tailored to diverse interconnectivity needs, Samtec takes centre stage as a world leader in the field. Equipped to meet any application's performance requirements or environmental challenges, Samtec connectors empower electronic devices with efficient and reliable interconnections.

To learn more and access Samtec technical resources & downloads, visit: https://www.mouser.com/manufacturer/samtec/

See the NEWEST PRODUCTS available from Mouser: https://www.mouser.co.uk/new/

References