Case Study: Wireless Charging of AGVs and AMRs Increases Productivity

25-04-2024 | By Jack Pollard

Marco van der Linden, country sales manager at PULS-Wiferion UK, says FFT (Flexible Fertigungstechnik/Flexible Manufacturing Technology) is one of the world’s leading suppliers of systems for automated, flexible manufacturing plants, and now use wireless charging for their AGVs.

FFT (Flexible Fertigungstechnik/Flexible Manufacturing Technology), located in central Germany, is recognised globally as one of the leading providers of systems for automated, flexible manufacturing plants.

As a comprehensive turnkey partner, FFT delivers customised production systems specifically designed for prominent industries such as automotive and aviation. The company's offerings encompass not only body shell production lines but also incorporate advanced automated maintenance concepts and sophisticated manufacturing cells that are crucial in final product assembly. Through its holistic turnkey approach, FFT assures its clients a seamlessly integrated solution that combines the production plant with all necessary materials handling operations.

Introduction of FFTigv AGV System

To enhance its service offerings and meet evolving customer demands for complete, flexible automation solutions, FFT has innovatively expanded its product range with the development of the FFTigv automated guided vehicle (AGV) system. This system is crafted to integrate flawlessly with existing production environments, providing FFT’s customers with a streamlined, highly efficient automation solution from a single source. The FFTigv is a reflection of FFT's commitment to engineering solutions that precisely align with and exceed client expectations for flexibility and efficiency in manufacturing processes.

Advanced Charging Technology in Use

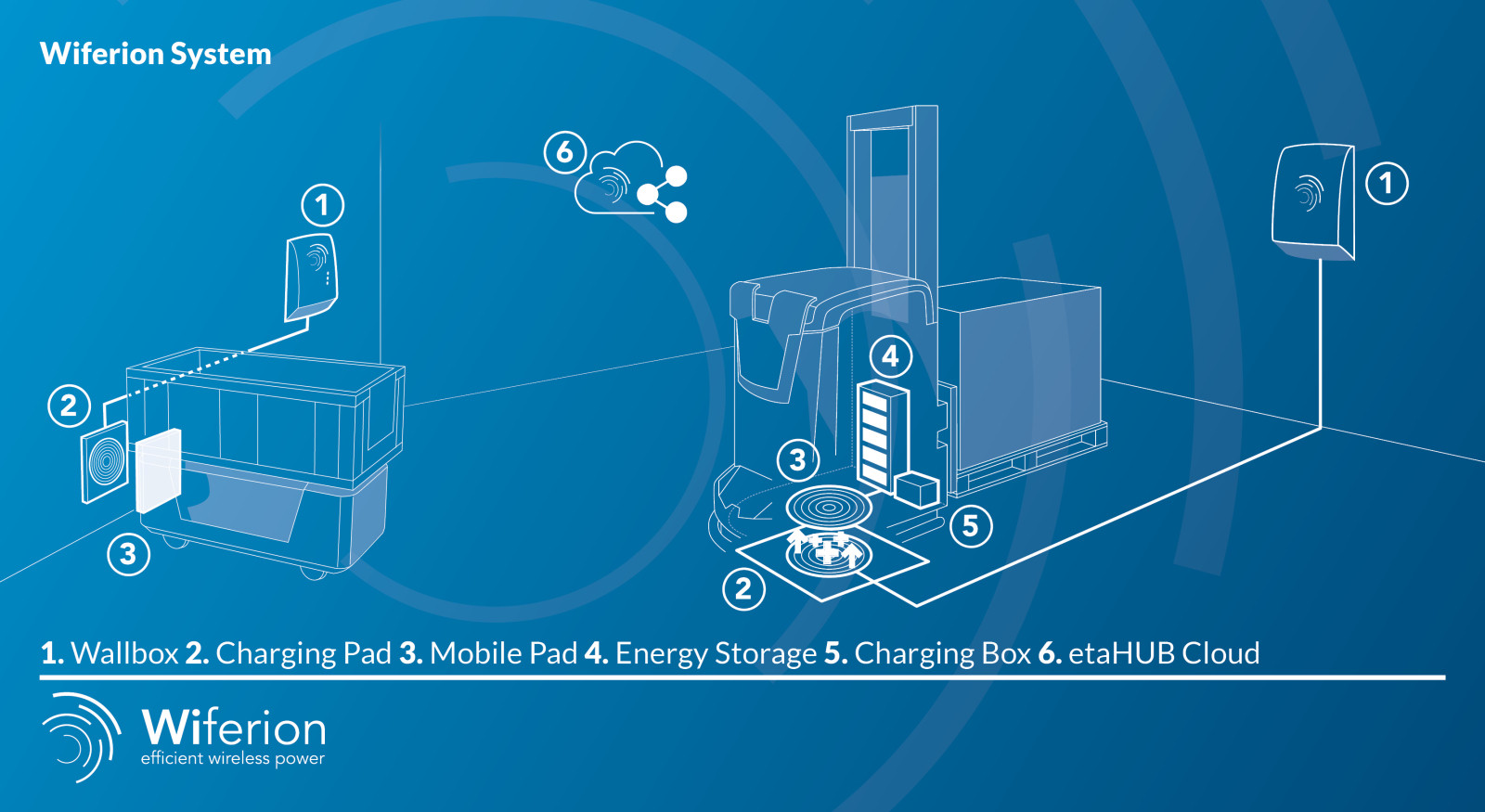

Central to the new FFTigv system is the adoption of the Wiferion by PULS charging technology. This choice was driven by the specific requirements of body shell construction, which include managing tight cycle times and accommodating heavily staggered cycles. With several thousand Wiferion by PULS etaLINK charging systems already in successful operation across various applications, it was a natural progression for FFT to incorporate this reliable technology into their new AGV system. The challenge lay in ensuring that the AGVs could manage the transport of heavy goods while being capable of rapid recharging with high currents. To address this, Wiferion by PULS has tailored an energy system comprising high-performance batteries coupled with efficient chargers designed to meet these high demands. Each FFTigv unit is equipped with two etaLINK 3000 fast charging systems that, when operated in parallel, produce a significant charging power of 6 kW, thus providing the batteries with energy at a fast charging rate of 2 C.

Real-World Applications of FFT Technology

The flexibility offered by the etaLINK fast charging system is a key advantage, allowing for the strategic placement of charging points at almost any frequently utilised location within a manufacturing or warehouse setting. This design enables robots to initiate the charging process automatically upon aligning with a charging point, with the system reaching full power within mere seconds. The "in-process" charging capability of the AGVs is critical, as it eliminates the need for charging breaks and reduces unproductive travel times to stationary charging stations. This continuous operational capability ensures that FFT's AGVs are available round-the-clock, thereby supporting the deployment of highly productive manufacturing lines, such as those observed at the BMW Group factory in Leipzig, where they significantly contribute to enhancing manufacturing efficiency and throughput.

About Wiferion by PULS

Wiferion by PULS, known for pioneering and leading the technology in wireless charging for mobile robots (AGVs/AMRs) and forklifts, became a vital part of PULS GmbH in 2023. The etaLINK family's inductive charging systems are specifically designed to eliminate unnecessary machine downtimes and significantly enhance fleet efficiency, offering long-term increases of up to 32%. The integration with PULS has generated considerable synergies, enhancing the capability to quickly bring new product concepts to market and providing improved support and services to customers worldwide. With a solid foundation supported by PULS Group's extensive resources, including more than 1,700 employees and modern production facilities located in the Czech Republic, China, and Germany, Wiferion by PULS is well-positioned to escalate its global scaling efforts, bolstering its role as a market leader in industrial charging solutions.

For more information please visit https://www.wiferion.com/en/.