Solid-State Batteries: The Real Game Changer for Electric Vehicles?

Insights | 12-03-2024 | By Paul Whytock

Key Things to Know:

- Solid-State Batteries: A promising advancement in EV technology, offering solutions to common lithium-ion battery issues like range inadequacy and fire hazards.

- Environmental Impact: While solid-state batteries eliminate the use of hazardous cobalt, the lithium mining process required for their production consumes significant water resources.

- Electric Double Layer (EDL) Challenge: A key technical hurdle in solid-state battery development, affecting surface resistance and overall battery performance.

- Future Prospects: Major automotive manufacturers, including Toyota, are investing heavily in solid-state technology, with a potential breakthrough expected by 2027.

Amidst the growing enthusiasm for electric vehicles (EVs) as a cornerstone of environmental sustainability, the reality of lithium-ion battery technology presents a complex array of challenges. Despite their pivotal role in the current EV landscape, these batteries grapple with limitations in range, charging time, weight, cost, and safety concerns. Moreover, the environmental and economic hurdles associated with their recycling process underscore the urgent need for innovative solutions in our journey towards a greener future.

The Lithium-Ion Dilemma: Navigating the First Lap in the EV Race

Despite the masses of hype that electric vehicles (EVs) are essential if we humans are going to seriously cut the carbon overload we are inflicting on our planet, the fact is that lithium-ion batteries are only the first transitional lap in a much longer ecological race.

They have problems that still don’t make them a climate game-changer. Prime amongst these are performance issues such as range inadequacy, they take too long to charge, they are heavy and expensive and because their electrolyte is liquid they can be a fire hazard if they are become faulty or are damaged.

In addition to those factors, they are not economically viable to recycle which means it remains cheaper to manufacturer new batteries which in turn means we will see ever-growing mountains of used lithium batteries that eventually leech toxic chemicals into the surrounding area.

Major Battery breakthrough

A battery technology that could deal with a number of those issues is now under serious development and it’s called solid-state. Car company Toyota says it’s on the verge of a major breakthrough that could resolve range anxiety, slow charging issues, size and weight problems and also reduce fire risk.

There are also a number of car-makers such as Ford, Hyundai and the Volkswagen Audi Group that have teamed up with various battery companies to accelerate the development of solid-state batteries.

All this sounds very positive, but like all breakthrough technologies, there are problems that researchers have to surmount, and the reality is that mass-produced, commercially viable solid-state batteries for EVs are a number of years away.

Understanding the Transition to Solid-State Technology

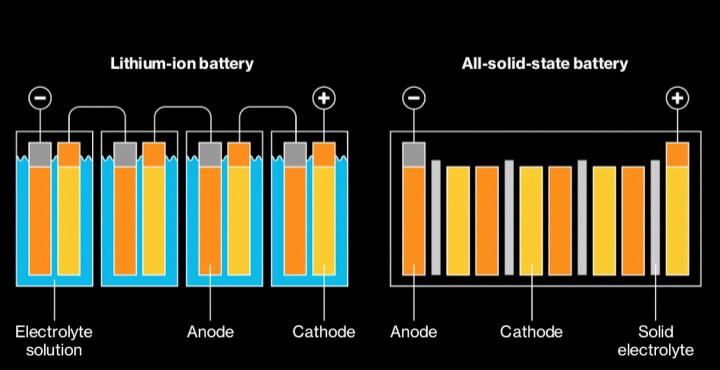

So what are the fundamental differences between lithium-ion batteries and solid-state designs? Much of the answers to that lies in the fundamental makeup of the electrolyte.

The solid-state concept uses a solid electrolyte, such as lithium phosphorus oxynitride, whereas lithium-ion batteries use liquid or gel electrolytes that require separators between the cathode and the anode to prevent those electrolytic substances from reaching each other. Failure of the separators through either poor manufacture or impact damage is what can cause a fire in an EV. By comparison, in solid-state batteries, it is actually the solid electrolyte that separates the cathode and anode poles, so they are far less prone to flammability.

One of the promising solid electrolytes being explored is lithium phosphorus oxynitride (LiPON). This material has been pivotal in the development of thin-film solid-state battery technology, offering a range of stoichiometries with varying properties. Understanding the nuances of LiPON, including its ionic conductivity and how it's affected by different preparation methods, is crucial for optimising solid-state batteries for electric vehicles. The exploration of LiPON underscores the innovative approaches being taken to overcome the limitations of current battery technologies and enhance their safety and efficiency [source].

This solid element of their design means that, in climate terms, they are more resilient to both hot and cold temperatures. It is cold temperatures that can impact the performance of lithium-ion batteries. Because liquid or gel electrolytes are more affected than solid electrolytes, the speed of the ions within them is reduced, which in turn reduces battery performance.

The Range Anxiety Advantage

When it comes to the range anxiety which haunts many existing owners of EVs or deters potential new customers, the solid-state design has an advantage. Because the electrolyte has a far denser structure it can store more electricity. This is where possible size and performance advantages come in. Currently EVs have to carry substantial battery weight which in term requires more energy to move the vehicle.

Solid-state batteries have options here. They could be made the same size as conventional lithium-ion and offer greater operating range, or, alternatively, they could be made smaller and lighter and offer similar operating range ability. They could also be made in a greater variety of shapes. Try to find me an automotive designer who wouldn’t like that flexibility when it comes to future vehicle shapes.

So, in summary, the advantages of solid-state batteries are that they are fire-safe, they have greater range, and there is evidence they charge more rapidly. They are also smaller, lighter and have a greater lifespan.

Environmental and Safety Benefits of Solid-State Batteries

Environmentally they have to be a better bet because unlike lithium-ion they do not use cobalt which is known to be extremely hazardous to humans and is carcinogenic.

But there is a but. They do use a lot of lithium and mining and manufacturing that requires huge quantities of water. This can often deprive surrounding areas of adequate water supplies for farming purposes and other manufacturing processes. So all is not perfect when it comes to the solid- state concept.

The environmental impact of lithium mining is a significant concern, particularly in terms of water usage. The process of extracting lithium involves pumping mineral-rich brine to the surface, which then evaporates over several months. This method consumes approximately 1.9 million liters of water per metric ton of lithium produced, raising sustainability concerns, especially in water-scarce regions. The lithium triangle in South America, a major source of the world's lithium, is one such area where mining activities have significantly affected local water resources, impacting communities and ecosystems [source].

Solving the EDL Factor

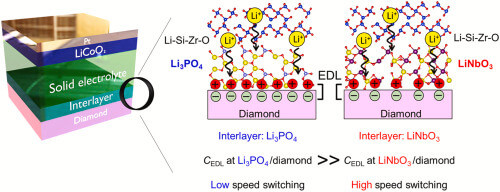

There are also some other operational elements that need sorting out, and prime amongst these is the EDL factor. This is a factor known as Electric Double Layer and it is this that is probably the cause of the high surface resistance of solid-state batteries and is the prime reason why they have not yet reached wide acceptance by EV makers.

The Electric Double Layer (EDL) phenomenon plays a critical role at the interface of solid electrolytes in solid-state batteries. It involves the accumulation of charge at the solid-to-solid interface, which can significantly affect the battery's performance. Understanding and mitigating the EDL effect is crucial for improving the surface resistance and overall efficiency of solid-state batteries. This area of research is vital for the development of solid-state batteries that meet the demands of electric vehicle manufacturers and consumers alike [source].

Exploring the Impact of the Electric Double Layer

So what is EDL? This characteristic happens at the interface of the solid-to- solid electrolytic interface. It occurs when colloidal particles gain negative electric charge by adsorbing the negatively charged ions of the dispersion medium on their surface. Consequently, researchers and car manufacturers are working hard to understand and resolve the problem.

In Japan, Dr Tohru Higuchi, associate professor at Tokyo University of Science (TUS) and other colleagues from TUS and Dr Takashi Tsuchiya and Dr Kazuya Terabe from Japan’s National Institute for Materials Science have developed a unique all-solid-state hydrogen-terminated diamond-based EDL transistor in order to take Hall measurements and pulse response measurements that determined EDL charging characteristics. This is used to determine the EDL effect at the solid/solid electrolyte interface.

By inserting a nanometre-thick lithium niobate or lithium phosphate interlayer between the diamond-based EDL transistor and lithium solid electrolyte, the team could investigate the electrical response of the EDL effect at the interface between these two layers.

The results showed that the makeup of the electrolyte did have an influence of the EDL in the area of the electrolyte interface. Most importantly the research also determined what material changes could assist with the reduction of EDL.

Understandably, details of these material options are not public knowledge at present but the work undoubtedly shows there are ways to resolve solid-state EDL effects.

Conclusion

Finally, let us conclude with a very positive statement from Japanese car maker Toyota. It has made bold public statements about its work with solid-state battery technology and is predicting that eventually, its battery technology will have a range of 1,200 Km and will reach a full charge in approximately 14 minutes.

Is this just marketing hyperbole or a real possibility? We’ll have to wait and see but Toyota make it clear that its roadmap indicates it will have commercially viable solid-state battery technology by 2027 and its already investing in large manufacturing facilities to enable that.

So yes. Solid-state EV batteries will be a game-changer when it comes to propelling our EVs but still only a transitional one . When it comes to the long-term protection of the World’s environment there is potentially an even bigger one waiting in the wings…hydrogen!

References:

- A Review on Lithium Phosphorus Oxynitride: https://www.osti.gov/servlets/purl/1772959

- 1 metric ton Lithium requires 1,9 million liter of water: https://247storage.energy/1-metric-ton-lithium-requires-19-million-liter-of-water/#:~:text=The%20lithium%20extraction%20process%20uses,rich%20brine%20to%20the%20surface.

- Department of Chemical Engineering and Biotechnology: https://www.ceb.cam.ac.uk/research/groups/rg-eme/Edu/the-electrical-double-layer